UC Davis

UC Davis Previously Published Works

Title

1D lignin-based solid acid catalysts for cellulose hydrolysis to glucose and nanocellulose

Permalink

https://escholarship.org/uc/item/1t4608p8

Journal

ACS Sustainable Chemistry and Engineering, 3(10)

ISSN

2168-0485

Authors

Hu, S

Jiang, F

Hsieh, YL

Publication Date

2015-10-05

DOI

10.1021/acssuschemeng.5b00780

Peer reviewed

eScholarship.org Powered by the California Digital Library

University of California

1D Lignin-Based Solid Acid Catalysts for Cellulose Hydrolysis to

Glucose and Nanocellulose

Sixiao Hu, Feng Jiang, and You-Lo Hsieh*

Fiber and Polymer Science, University of California-Davis, One Shields Avenue, Davis, California 95616, United States

*

S

Supporting Information

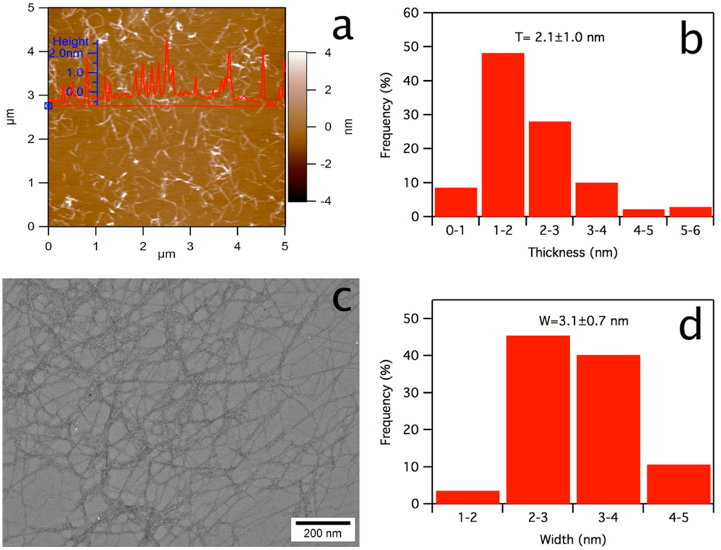

ABSTRACT: One-dimensional (1D) solid acid catalysts have

been synthesized from lignin-based activated carbon fibers via

sulfonation and hydrothermal treatment to be mesoporous and

contain 0.56 mmol/g sulfonic and 0.88 mmol/g total acid for

direct hydrolysis of highly crystalline rice straw cellulose (CrI =

72.2%). Under optimal hydrothermal conditions of 150 °C

and 5 atm, 69.8% of cellulose was hydrolyzed in three

consecutive runs, yielding 64% glucose at 91.7 selectivity as

well as 8.1% cellulose nanofibrils (2.1 nm thick, 3.1 nm wide,

and up to 1 μm long). These 1D acid catalysts could be used

repetitively to hydrolyze the remaining cellulose as well as be

easily separated from products for hydrolysis of additional cellulose. In essence, complete valorization of rice straw cellulose has

been demonstrated by direct hydrolysis with these 1D acid catalysts to superior glucose selectivity while generating high value

cellulose nanofibrils.

KEYWORDS: Solid acid catalysts, Mesoporous, Activated carbon fibers, Hydrolysis, Glucose, Cellulose nanofibrils

■

INTRODUCTION

Heterogeneous solid acid catalysts are particularly suited for

large-scale industrial operations due to their many advantages

over homogeneous liquid phase catalysts. Heterogeneous solid

acid catalysts are noncorrosive and safe and can function more

efficiently under continuous flow than the typical batch

operations of homogeneous liquid acid catalysts.

1

In solid

acid catalysis, the reactants can be activated directly by protons

generated from the acid sites or via hydrogen spillover from

other active phases in the system.

2

The products could be easily

separated to allow recovery and reuse of the solid catalysts.

Various solid acid catalysts, such as zeolite,

3−6

silica,

7−12

hydrous zirconia,

12

nafion

13−15

and carbons,

16−19

have been

developed for common chemical reactions, including ester-

ification,

3,12,16

alcohol dehydration,

7,13

and hydrolysis.

18,19

Solid catalysts have also been reported in the hydrolysis of

cellulose for biofuel production, including nafion,

15

zeolite,

20

Fe

3

O

4

magnetic nanoparticles bearing mesoporous silica,

21

nano Zn-Ca-Fe oxide,

22

as well as a wide range of cellulose

chars and activated carbon particulates.

18,19,23−29

Among them,

carbon solid acid catalysts have exhibited particularly high

activity because of their high acid densities and strong

interactions with the β-1,4-glycosidic bonds in cellulose.

28

An

exceptional 74% glucose yield was achieved under hydro-

thermal conditions using sulfonated ordered mesoporous

carbon derived from a silica template.

18

However, either ball

milling

18,26,29

or ionic liquid dissolution of cellulose

27

was

necessary to enhance contact or diffusion to destruct the

crystalline structure of cellulose. To overcome the accessibility

issue, smaller Zn-Ca-Fe oxide nanoparticle catalysts have been

shown to significantly increase the hydrolysis of crystalline

cellulose into glucose and oligosaccharides.

22

Separation of

zero-dimensional nanocatalysts from the hydrolysate products

is, however, difficult. Therefore, solid acid catalysts with high

acid densities and yet geometries that allow easy separation for

reuse would be of significant interest. Furthermore, solid acid

hydrolysis of cellulose should generate nanocellulose, but this

has only been reported on solid cationic exchange polystyrene

resin beads (NKC-9 with 4.7 mmol/g acid density).

30

This study aimed to synthesize one-dimensional (1D) solid

acid catalysts for direct hydrolysis of crystalline cellulose for

simultaneous production of sugars and high valued nano-

cellulose. The 1D solid acid catalysts were prepared from

sulfonation of submicron-sized activated carbon fibers (ACFs)

using concentrated sulfuric acid. The ultrafine ACFs were

electrospun from lignin and simultaneously carbonized and

activated at 900 °C to high specific surface (1400 m

2

/g) and

pore volume (0.7 cm

3

/g).

31

The solid acid catalysts from lignin-

based ACFs have several advantages and desired attributes over

other solid acid catalysts for hydrolysis of crystalline cellulose.

Lignin, an abundant and underutilized biomass fraction, is an

excellent carbon precursor, and lignin chars are less recalcitrant

than rigid graphitic carbons, such as carbon nanotubes,

18

to be

readily sulfonated by concentrated sulfuric acid, a much safer

alternative than the commonly used fuming sulfuric acid for

sulfonation of graphitic carbons. These 1D solid acid catalysts

Received: July 29, 2015

Revised: August 21, 2015

Published: August 21, 2015

Research Article

pubs.acs.org/journal/ascecg

© 2015 American Chemical Society 2566 DOI: 10.1021/acssuschemeng.5b00780

ACS Sustainable Chem. Eng. 2015, 3, 2566− 2574

can be directly mixed with untreated semicrystalline cellulose.

ACFs, with the high aspect ratio, submicron diameters, and

porous structures are expected to be in more intimate contact

with cellulose, affording shorter access to the active sites and

better interconnected diffusive pathways for rapid and efficient

hydrolysis while minimizing deactivation of the catalysts. The

continuous fibrous form of the solid acid catalysts can be easily

separated from the soluble products via simple filtration for

repetitive use.

■

EXPERIMENTAL SECTION

Materials. Pure cellulose was isolated from rice straw (Calrose

variety) by extraction with 2:1 v/v toluene/ethanol and subsequent

dissolution of lignin and hemicellulose/silica with acidified NaClO

2

(1.4 wt %, 70 °C, 5 h) and alkaline KOH (5 wt %) at 90 °C for 2 h

resulting in 36% yield and 72.2% crystallinity.

32,33

Poly(ethylene

oxide) (PEO) (M

w

= 600 kDa), alkali lignin (low sulfonate) (AL

ls

)

(M

w

= 60 kDa, spruce origin) were acquired from Sigma-Aldrich

(USA), sodium hydroxide (anhydrous NaOH pallets, A.C.S. grade, 85

wt % minimum purity), aqueous NaOH (1N), sulfuric acid (95−98 wt

% purity), dinitrosalicylic acid (98 wt % purity), sodium sulfite

anhydrous (98 wt % minimum purity), potassium sodium tartrate

tetrahydrate (A.C.S. grade), and water (HPLC grade) were from

Fisher Scientific (USA). All of the chemicals were used as received.

Synthesis of Solid Acid Catalysts. Both carbon fibers (CFs) and

activated carbon fibers (ACFs) were synthesized according to a

previously reported approach.

31

Briefly, aqueous 9:1 w/w AL

ls

/PEO

(10 wt % total concentration) mixtures without and with NaOH at a

1:2 w/w NaOH/lignin ratio were electrospun into CF and ACF

precursor fibers, respectively. The precursor fibers were placed in a

quartz tube (2 cm inner diameter) of an electric furnace (Mini-Mite,

Lindberg/Blue), heated at 10 °C min

−1

under flowing N

2

at 100 mL

min

−1

to 105 °C, held for 0.5 h to drive off moisture, and then to 600

(CFs) or 900 °C (CFs and ACFs), held for another 0.5 h, and finally

cooled to ambient temperature under flowing N

2

at 100 mL min

−1

.

CFs and ACFs were then washed with deionized water repeatedly to

remove residual alkali metals and other small hydrocarbon impurities

followed by oven drying at 60 °C for 12 h.

Dried CFs and ACFs were sulfonated with concentrated sulfuric

acid at 110 or 150 °C for 20 h (5 mg/mL solid/liquid ratio, 1 atm) to

obtain sulfonated CF (SCFs) and ACFs (SACFs), respectively. SACFs

were rinsed thoroughly with 70 °C water to remove residual sulfuric

acid and then heated in water at 150 °C and 5 atm for 24 h using a 100

mL poly(tetrafluoroethylene) cylindrical reactor to obtain the

hydrothermal-treated SACFs. Hydrothermal-treated SACFs sulfonated

at 150 °C were further characterized and used in the hydrolysis of

cellulose and were denoted as HTSACFs unless specified otherwise.

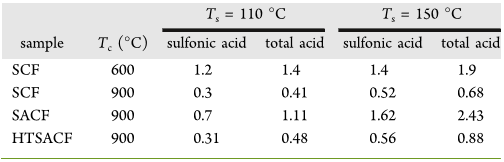

Hydrolysis of Cellulose. Solid HTSACFs catalyst (160 mg) and

cellulose (40 mg) were dispersed in 32 mL of water in a 100 mL PTFE

cylindrical reactor, hermetically sealed, and heated in 110, 130, and

150 °C oil baths for 24 h with corresponding pressures of 1.4, 2.8, and

5.0 atm, respectively. The catalysts and remaining cellulose were

vacuum filtered (Whatman No. 1, dried, and weighed to 0.1 mg). The

average mass of the remaining cellulose and the catalysts (m

cell+HTSACF

)

from five reactions were used to determine the extent of cellulose

hydrolysis via eq 1. For repetitive hydrolysis, the dried HTSACF

catalysts along with the remaining cellulose were redispersed to 32 mL

of water and heated at 150 °C for a second and then a third time with

drying and weighing in between to determine the extent of cellulose

hydrolysis for each repetition. The filtrates were thoroughly dialyzed

(12−14 kDa MWCO, Fisher brand) to exchange the sugars in the

aqueous environm ent and retain nanocellulose in the dialysis

membrane. The glucose produced was quantified by the colorimetric

assay as described later. The nanocellulose yield was determined

gravimetrically by weighing dried nanocellulose and reported as a

percentage of the original cellulose.

=

−

×

+

m

cellulose hydrolysis (wt %)

160

40

100%

cell HTSACF

(1)

Analytical Methods. The chemical structures of ACFs, SACFs,

and HTSACFs were examined by Fourier transform infrared

spectroscopy (FTIR) (Nicolet 6700, Thermo Scientific), and their

morphologies were characterized by scanning electron microscope

(SEM) (FEI-XL 30, FEI) and atomic compositions by energy-

dispersive X-ray spectroscopy (EDX) adjunct to the SEM. All samples

were washed thoroughly with deionized water and dried at 60 °C for at

least 12 h before characterization. All FTIR spectra were collected

from samples pressed with anhydrous KBr powders into pellets. All

samples were sputter coated with gold for 1 min and imaged by SEM,

and noncoated samples were analyzed by EDX under a working

voltage of 5 kV. The acid density of the catalysts was analyzed via

conductometric titration using a pH/con ductivi ty meter (510,

OAKTON). For each titration, 10 mg of the acid catalysts were

dispersed in 15 mL of water, and 0.02 N NaOH was added to

neutralize the acids. The surface acid density (σ, in mmol/g of the

solid acid catalyst) was calculated from eq 2, where c is the NaOH

concentration (in N), m is the mass of the catalyst (in g), and V is the

volume of NaOH (in mL) used to neutralize the sulfonic acid and total

acids on the catalysts.

σ =

V

m

c

(2)

For surface area and pore characterization, the ACFs, SACFs, and

HTSACFs were dried at 50 °C for 48 h and then measured at 77 K by

a nitrogen adsorption−desorption analyzer (ASAP 2020, Micro-

metics). The single point total pore volume was estimated from

nitrogen adsorption at a relative pressure P/P

o

close to 1.The

Brunauer−Emmett−Teller (BET) surface area was calculated from the

isotherm in the BET linear region where relative pressure P/P

o

ranged

from 0.05 to 0.3. The mesopore surface area was derived from the

adsorption branch whereas pore and neck size distributions were

derived from both adsorption and desorption branches of the isotherm

using the Barret−Joyner−Halenda (BJH) method. To derive micro-

pore characteristics from the adsorption−desorption isotherm with

incomplete data below 0.05 P/P

o

relative pressure, micropore surface

area and pore hydraulic diameter distributions from 0.7 to 1.6 nm were

derived from a t-plot using the Mikhail, Brunauer, and Bodor MP

method

34

and the Harkins and Jura equation.

35

Micropore volume

(V

mp

) was derived from the tangent line of a contiguous range of the t-

plot using the surface area of the filled pores via eq 3

=

−+

×

+−

V

SS tt()()

2

15.47

nn nn

mp

11

(3)

where S

n

and t

n

are the surface area derived from the slope of the

tangent and the thickness of the adsorbed layer at the n point in the t-

plot, respectively, and 15.47 was the constant for converting gas

volume to liquid volume at STP.

The mixed HTSACF catalysts/cellulose (4:1) before and after three

consecutive reactions (32 mL of water and 150 °C) were sonicated in

a water bath (Branson 2510) for 10 min and then visualized under a

polarizing light microscope (PLM, LEICA DM 2500). The nano-

cellulose separated from the catalyst by dialysis was diluted 10×,of

which 10 μL was deposited onto a freshly cleaved mica surface, air-

dried, and scanned using an atomic force microscope (AFM, MFP 3D,

Asylum Research) under ambient air conditions in the tapping mode

with OMCL-AC160TS standard silicon probes at 1 Hz scan rate and

512 × 512 pixel resolution. The height image and pro file were

processed with Igor Pro 6.21 loaded with MFP3D 090909 + 1409, and

the average thickness was determined from ∼100 individual

nanocellulose. Using a transmission electron microscope (TEM), a

diluted nanocellulose suspension (5 μ L) was deposited onto glow-

discharged carbon-coated grids (300 mesh copper, Formvar-carbon,

Ted Pella Incorporated, Redding, CA) with excess liquid being

removed by blotting with filter paper after 10 min, negatively stained

with 2 wt % uranyl acetate solution for 5 min, and observed using a

Philip CM12 TEM operated at 100 kV accelerating voltage. The width

ACS Sustainable Chemistry & Engineering Research Article

DOI: 10.1021/acssuschemeng.5b00780

ACS Sustainable Chem. Eng. 2015, 3, 2566− 2574

2567

of the nanocellulose was measured from ∼100 individual nanofibrils

using an image analyzer (ImageJ, NIH, USA).

The water-soluble hydrolysates (10 μL) were injected into a 0.32

mm × 100 mm Hypercarb column, and the compositions were

analyzed by LC-MS (Thermo Scientific, USA). A standard reverse-

phase gradient utilizing 5 mM ammonium formate as solvent “A” and

acetonitrile as solvent “B” was run at a 25 μL/min flow rate for 12 min.

The eluent was monitored for negative ions by an orbitrap XL

(Thermo Scientific, USA) operated in the centroid mode at 4.5 kV

spray voltage, 275 °C capillary temperature, and 20 sheath gas setting.

Spectral data were acquired at a 30,000 fwhm resolution setting with

the lockmass feature, which has a typical mass accuracy of <2 ppm.

The glucose concentration was derived from the colorimetric assay.

36

Briefly, 100 mL of 1 wt % dinitrosalicylic acid reagent (DNS) solution

was prepared by mixing 1 g of dinitrosalicylic acid, 1 g of sodium

hydroxide, and 50 mg of sodium sulfite. Then, 1.5 mL of DNS solution

and 1.5 mL of hydrolysate were mixed and then heated at 90 °C for 10

min to develop the red-orange color, which was stabilized by

subsequently adding 1 mL of 40 wt % potassium sodium tartrate

solution. U pon cooling to ambient temperature, the UV− vis

absorbance of the stabilized solution was measured (Evolution 600,

Thermo Scientific) at 575 nm. Their sugar concentrations were

derived from the standard calibration using glucose solutions in 0.125

to 1.25 mg/mL concentrations (Figure S1). The glucose yield and

selectivity were calculated based on the original cellulose (40 mg) via

eqs 4 and 5, respectively, where C

g

is the glucose concentration (mg/

mL) determined by colorimetric titration and V

g

is the volume of the

hydrolysate (mL).

=

×

×

CV

glucose yield (%)

40

100%

gg

(4)

=×glucose selectivity (%)

glucose yield

cellulose hydrolysis

100%

(5)

■

RESULTS AND DISCUSSION

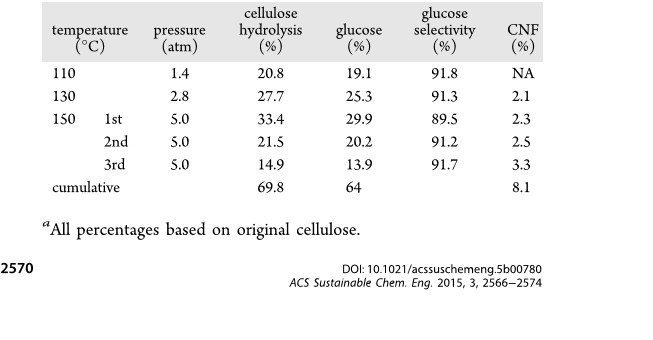

Acid Density and Chemical Structures of Solid Acid

Catalysts. Sulfonated carbon fibers (SCFs) and sulfonated

activated carbon fibers (SACFs) were prepared under two

carbonization (T

c

= 600 or 900 °C) and sulfonation (T

s

= 110

or 150 °C) temperatures (Table 1). The SACFs carbonized at

900 °C were also hydrothermal-treated (150 °C, 5 atm, 24 h)

to obtain HTSACFs. The acid densities were determined by

conductometric titration where conductivity typically decreased

sharply from neutralization of sulfonic acid groups, then stayed

constant as the weaker carboxylic acid was consumed, and

finally increased after all acid sites were neutralized with NaOH

addition (Figure S2). In all titration curves, sulfonic acid was

shown to be dominant with much lower extents of carboxylic

acid groups. Although sulfonic acid is expected from the

sulfonation reaction, carboxylic acid groups are likely from

oxidation of the reductive hydroxyl groups during prolonged

sulfonation.

Both sulfonic and total acid densities were higher for SCFs

carbonized at the lower 600 °C T

c

and for all fibers sulfonated

at the higher 150 °C T

s

(Table 1). SCFs carbonized at the

higher 900 °C had approximately 1/4 to 1/3 of the respective

sulfonic and total acid densities, i.e., 0.3 and 0.41 mmol/g at T

s

= 110 °C and 0.52 and 0.68 mmol/g at T

s

= 150 °C,

respectively, of those carbonized at 600 °C. Sulfonation of

ACFs (T

c

= 900 °C) at the respective T

s

of 110 and 150 °Con

SACFs, on the other hand, doubled and tripled the sulfonic and

total acid quantities relative to the corresponding SCFs.

Although the more rigid carbon structures produced at the

higher carbonization temperature of 900 °C are more difficult

to be sulfonated, hence lower acid densities, higher specific

surface ACF could only be produced at 900 °C. The greater

sulfonation effects on ACFs are due to their higher internal

surfaces as well as the carbon microstructure defects introduced

by alkali hydroxide activation.

37

Most significantly, the higher

sulfonation temperature produced increases in sulfonic and

total acids on the activated SACFs that were more pronounced

than on the SCFs. Overall, the SACFs carbonized at higher 900

°C still had a much higher acid density than SCFs carbonized at

lower 600 °C and therefore were hydrothermally treated to

prepare stable solid acid catalysts. Following hydrothermal

washing (150 °C, 5 atm, 24 h), the sulfonic and total acid

densities of HTSACFs sulfonated at 110 and 150 °C declined

significantly by 55% (0.31 and 0.48 mmol/g) and 65% (0.56

mmol/g and 0.88 mmol/g), whereas their mass decreased to

lesser degrees of 5 and 9%, respectively. The substantial losses

of sulfonic and total acids coupled with some mass losses from

hydrothermal washing suggest that sulfonation of the pore

surfaces may have led to fragmentation and solubilization of

small hydrocarbons. Both surface acid densities and catalyst

mass remained unchanged following a second hydrothermal

washing, showing no further leaching. That these acid sites

remain stable under the hydrothermal catalysis condition is a

critical attribute for HTSACF solid acid catalysts to be effective

in repetitive use. HTSACFs sulfonated at 150 °C with higher

sulfonic (0.56 mmol/g) and acid (0.88 mmol/g) densities was

used as the solid acid catalyst for the hydrolysis of cellulose to

be described later.

The presence of carboxylic and sulfonic acid groups on

ACFs, SACFs, and HTSACFs was further confirmed by FTIR

and EDX. Both FTIR spectra of SACFs and HTSACFs showed

aCO peak at 1720 cm

−1

but no evidence of the C−OH peak

at 1630 cm

−1

(Figure 1a), indicating complete oxidation of C−

OH to carbonyl and carboxylic acid by the concentrated

sulfuric acid. Aromatic skeletal st retching at 1580 cm

−1

,

expected from the polycyclic aromatic structures in all three

activated carbons, was also clearly present. In addition, EDX

showed the O content to be tripled from 4.4 wt % in ACFs to

12.7 wt % in SACFs in which 2.8 wt % of S was also detected

(Figure 1b). The hydrothermal treatment significantly lowered

the respective O and S contents in SACFs to 7.3 and 0.9 wt %

in HTSACFs. Such elemental com position changes were

consistent with the decreases in sulfonic and total acid densities

presented previously and attributed to the dissolution of the

highly oxidized and sulfonated hydrocarbons from the

hydrothermal treatment.

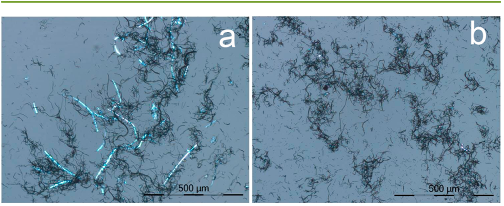

Morphologies and Porous Structures of the Solid

Acid Catalysts. ACFs were 500 nm to 2 μm wide and most

were over 100 μm long (Figure 2a and b). Sulfonation caused

SACFs to fragment into a few tens of micrometers in length.

This obvious length reduction is attributed to the extreme

Table 1. Sulfonic and Total Acid Density (mmol/g) of

Sulfonated Carbon Fibers (SCFs) and Sulfonated Activated

Carbon Fibers (SACFs) Prepared at the Prescribed

Carbonization (T

c

) and Sulfonation (T

s

) Temperatures

T

s

= 110 °C T

s

= 150 °C

sample T

c

(°C) sulfonic acid total acid sulfonic acid total acid

SCF 600 1.2 1.4 1.4 1.9

SCF 900 0.3 0.41 0.52 0.68

SACF 900 0.7 1.11 1.62 2.43

HTSACF 900 0.31 0.48 0.56 0.88

ACS Sustainable Chemistry & Engineering Research Article

DOI: 10.1021/acssuschemeng.5b00780

ACS Sustainable Chem. Eng. 2015, 3, 2566− 2574

2568

oxidation in concentrated sulfuric acid and the mechanical

forces from ma gnetic agitation (Figure 2c and d). The

hydrothermally washed HTSACFs remained similarly frag-

mented but showed no further morphological changes (Figure

2e and f). All three fibers, i.e., ACFs, SACFs, and HTSACFs,

appeared similarly porous with surface macropores in the tens

of nanometers range (Figure 2b, d, and f).

The porous structures of ACFs, SACFs, and HTSACFs were

further analyzed by BET nitrogen adsorption to all exhibit type

IV adsorption − desorption isotherms (Figure 3a) typical of

microporous and mesoporous materials. Each showed a step-

down at 0.45 relative pressure in the desorption isotherm

(Figure 3a) and an artificial peak at 4 nm (Figure 3b),

suggesting an ink-bottle porous structure with a neck size

smaller than 5 nm.

38,39

The sulfonation reaction slightly and

hydrothermal treatment more prominently shifted the meso-

pores to larger pore sizes and wider ranges ( Figure 3b and c).

Sulfonation slightly increased the mesopore (5−30 nm) surface

area and volume from 407 m

2

/g to 416 m

2

/g and from 0.71 to

0.75 cm

3

/g, respectively (Figure 3c), but significantly decreased

micropore (0.5−0.8 nm) surface area and volume from 444 to

305 m

2

/g and 0.18 to 0.13 cm

3

/g, respectively (Figure 3d),

resulting in a slight decrease in the total BET surface area (885

to 752 m

2

/g) and pore volume (0.9 to 0.88 cm

3

/g).

Figure 1. (a) FTIR and (b) EDX of ACF, SACF, and HTSACF. Inset in (b): elemental composition (wt %).

Figure 2. SEM of (a,b) ACFs, (c,d) SACFs, and (e,f) HTSACFs.

ACS Sustainable Chemistry & Engineering Research Article

DOI: 10.1021/acssuschemeng.5b00780

ACS Sustainable Chem. Eng. 2015, 3, 2566− 2574

2569