HAL Id: hal-02383394

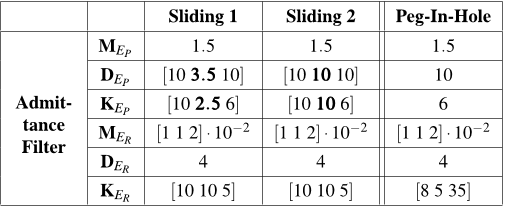

https://hal.laas.fr/hal-02383394

Submitted on 27 Nov 2019

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of sci-

entic research documents, whether they are pub-

lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diusion de documents

scientiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

6D interaction control with aerial robots: The ying

end-eector paradigm

Markus Ryll, Giuseppe Muscio, Francesco Pierri, Elisabetta Cataldi, Gianluca

Antonelli, Fabrizio Caccavale, Davide Bicego, Antonio Franchi

To cite this version:

Markus Ryll, Giuseppe Muscio, Francesco Pierri, Elisabetta Cataldi, Gianluca Antonelli, et al.. 6D

interaction control with aerial robots: The ying end-eector paradigm. The International Journal

of Robotics Research, SAGE Publications, 2019, 38 (9), pp.1045-1062. �10.1177/0278364919856694�.

�hal-02383394�

6D Interaction Control with Aerial

Robots: The Flying End-Effector

Paradigm

Accepted for The International Journal of

Robotics Research 2019

Preprint version,

final version at

https://journals.sagepub.com/loi/ijra

Markus Ryll

1

, Giuseppe Muscio

2

, Francesco Pierri

2

, Elisabetta Cataldi

3

, Gianluca

Antonelli

3

, Fabrizio Caccavale

2

, Davide Bicego

1

and Antonio Franchi

1

Abstract

This paper presents a novel paradigm for physical interactive tasks in aerial robotics allowing to increase reliability and

decrease weight and costs compared to state of the art approaches. By exploiting its tilted propeller actuation, the robot

is able to control the full 6D pose (position and orientation independently) and to exert a full-wrench (force and torque

independently) with a rigidly attached end-effector. Interaction is achieved by means of an admittance control scheme

in which an outer loop control governs the desired admittance behavior (i.e., interaction compliance/stiffness, damping,

and mass) and an inner loop based on inverse dynamics ensures full 6D pose tracking. The interaction forces are

estimated by a IMU-enhanced momentum based observer. An extensive experimental campaign is performed and four

case studies are reported. Firstly, a hard touch and slide on a wooden surface, named sliding surface task. Secondly, a

tilted peg-in-hole task, i.e., the insertion of the end-effector in a tilted funnel. Then an admittance shaping experiment in

which it is shown how the stiffness, damping and apparent mass can be modulated at will. Finally, the fourth experiment

is in charge of showing the effectiveness of the approach also in the presence of time-varying interaction forces

Keywords

Aerial robotics, Aerial physical interaction, Aerial Manipulation

INTRODUCTION

Direct physical interaction of a robot with its environment

is a vast and continuously growing field of research with

several relevant applications. Industrial case studies have

been object of massive research, see, e.g., Villani and

De Schutter (2008) for an introductory reading. Recently,

the use of aerial robotic platforms, possibly equipped with

an arm, came prominently into focus. Aerial robots offer

a nearly unlimited motion space and can be exposed in

dangerous or poisonous environments. Along this line,

aerial robots have been recently exploited in operations

such as, e.g., transportation (Fink et al. (2011)), structure

assembly, object grasping (Augugliaro et al. (2014)), and

wall inspection (Fumagalli et al. (2012)), requiring both

autonomous flight competences and physical interaction

capabilities; the latter being a particularly challenging task

due to the complexity of aerodynamics – especially when

the vehicle is close to surfaces – and intrinsic instability of

almost all the aerial robotic platforms.

To perform physical interaction, aerial robots are either

equipped with a rigid tool or an n degree of freedom (DoF)

robotic arm. In the first case, the tool is rigidly fixed to

the airframe, see, e.g., Gioioso et al. (2014b); Augugliaro

et al. (2014); Y

¨

uksel et al. (2014b); Nguyen and Lee (2013);

Gioioso et al. (2014a). A drawback of this solution is that

typical aerial platforms are underactuated and therefore it is

impossible to independently control the 6D (position plus

orientation) dynamics of the end-effector. This limits the

potential use cases and also creates stability issues. In fact, it

has been shown that in the presence of interaction with points

of the airframe different from the vehicle’s center of mass

(CoM) the internal dynamics of underactuated multi-rotors

is not guaranteed to be stable, and it is, in general, neither

easy to stabilize nor practical for real applications (Nguyen

and Lee (2013)).

The second possibility is to attach an n-DoF robotic arm

to the aerial platform (Muscio et al. (2016, 2017); Baizid

et al. (2016); Kim et al. (2013); Tognon et al. (2017)),

a solution which aims at overcoming the underactuation

of the end-effector dynamics by exploiting the increased

number of actuators provided by the arm. In this way, a fully

actuated 6D force control at the end-effector side becomes

possible (Yang and Lee (2014)). However, this solution

comes with several drawbacks as well, which are mentioned

in the following:

i) a robotic arm strongly decreases the payload and flight

time due to its own weight;

ii) the system is much more complex from a mechanical

point of view than a single airframe with a rigid tool and,

thus, it is more expensive to build and also requires more

maintenance and repairing costs across its operational life;

1

LAAS-CNRS, Universit

´

e de Toulouse, CNRS, Toulouse, France,

2

University of Basilicata, School of Engineering, via dell’Ateneo Lucano,

10, Potenza, Italy,

3

University of Cassino and Southern Lazio, Via Di Biasio 43, 03043

Cassino, Italy

Corresponding author:

Antonio Franchi, LAAS-CNRS, Universit

´

e de Toulouse, CNRS, Toulouse,

France.

Email: antonio.franchi@laas.fr

Preprint, final version at https://journals.sagepub.com/loi/ijra

2 Accepted for The International Journal of Robotics Research 2019

iii) lateral forces in body frame, which cannot be provided

by the aerial platform itself, have to be generated through the

dynamical/inertial coupling between the arm and the aerial

robot: the proper mastering of the dynamical coupling is

something that has to be necessarily exploited in order to

get the sought benefits in terms of 6D force control. This, in

turn, requires the knowledge of the precise dynamical model

and a very accurate measurement of the system inputs and

states (position, orientation, linear and angular velocities).

As a matter of fact, these requirements are extremely hard to

achieve in real world conditions (especially the former). For

this reason, kinematic-only approaches have been preferred

for real world validations, see e.g., Muscio et al. (2016,

2017), at the expense of losing the main benefits for which

the manipulator was introduced.

As a byproduct, the use of such complex systems has

been exploited in real world so far only for basic interaction

tasks such as, e.g., pick and place, vertical insertion,

and pull/pushing of constrained objects like drawers (Kim

et al. 2015). At the best of our knowledge, more complex

interactions required in real world like: a) peg in-hole

with non-vertical orientation, b) position-force control for

sliding on surfaces, and, more in general, c) an accurate

shaping of the full 6D force/moment interaction of the end-

effector with the environment; have not yet been successfully

demonstrated in real world in state-of-the-art systems.

Summarizing, standard flying platforms are underactuated

and, thus, incapable of 6D end-effector force control. On the

other side, using a full manipulator up in the air to perform

the sought 6D end-effector force control is often excessively

complex and may introduce more problems than benefits.

To solve all these problems at once and finally achieve

the sought full 6D force control of the aerial interaction,

we propose a novel paradigm which we named the Flying

End-Effector. The concept is based on the ascertainment

that the overall mission goal is to achieve 6D interaction

with an end-effector. While in ground robotics the end-

effector must be actuated by a manipulator with at least six

degrees of freedom (DoF), in the aerial robotics case there

is no necessity to bring up to the air a full manipulator

together with the end-effector. What is instead needed is

that the aerial robot possesses the minimal requirements

to perform such interaction with a rigidly attached end-

effector. In order to achieve such requirements, we propose

to use a multi-rotor robot with non-collinear fixedly-tilted

propellers (NCFTP) instead of the more common collinear

fixedly-tilted propeller (CFTP) architectures (Ryll et al.

(2016)). In NCFTP platforms, which appeared in the robotics

literature only recently (see, e.g., Rajappa et al. (2015);

Voyles and Jiang (2014); Brescianini and D’Andrea (2016);

Park et al. (2016)), the full-actuation is achieved by a more

general propeller position and orientation. The difference

between the underactuated platform and NCFTP platforms

is that, in the former approach, all the propellers have

the same orientation while, in the latter approach, every

propeller orientation is different. The NCFTP approach is,

thus, able to control independently the translational and

angular acceleration when unconstrained, or any of the six

components of the exerted wrench when in contact, thus

allowing full and dexterous 6D force control, which makes

them much more suited for physical interaction tasks than

standard CFTP platforms.

Another solution to obtain full-actuation consists of

actively tilting the whole propeller groups (Ryll et al. (2016,

2015); Long and Cappelleri (2013)), a solution which is

called thrust vectoring or tilting propeller. This solution

however is subject to the same drawbacks of the solutions

employing a manipulator arm, since they require extra

actuation, mechanical complexity, and weight. Furthermore,

they cannot in general guarantee instantaneous disturbance

rejection or fast force exertion since the propellers might

have to be re-oriented, which again takes some non-

negligible time.

A critical issue for aerial robot interaction control is the

measurement of the interaction wrench. A reliable solution

is the adoption of force/torque sensors, such as in Antonelli

et al. (2016) where the wrench measurement of a wrist

mounted sensor of an aerial manipulator is fed to an

admittance filter. Use of force/torque sensor increases the

cost and the weight of the aerial platform, thus alternative

solutions based on wrench estimators have been proposed

in the last years. In Y

¨

uksel et al. (2014a) a Lyapunov-

based nonlinear observer is proposed for estimating the

external wrenches applied on a quadrotor, while in Tomic

and Haddadin (2014) a hybrid estimation is proposed, using

the linear acceleration for directly computing the interaction

forces and a momentum based observer for estimating

the interaction torques. In Tomic et al. (2017) the same

authors propose a more refined hybrid estimation, where

the estimated forces are not simply computed by the model

but are obtained via a first-order stable filter, similar to

the solution proposed in Y

¨

uksel et al. (2014a). In Rajappa

et al. (2017), the authors, by exploiting both a wrench

estimation and a ring of eight contact sensors, proposed

a control able to separate human interaction forces from

additional disturbances as wind and parameter uncertainties.

In Tagliabue et al. (2016) as well an admittance control

framework is used for collaborative transportation of objects

by using underactuated aerial robots, an approach which is

theoretically analyzed and refined in Tognon et al. (2018) by

demonstrating its stability and the fundamental role of the

internal force in such control scheme.

A preliminary (6-pages long) version of this work has been

presented in a conference version (Ryll et al. (2017)). With

respect to Ryll et al. (2017), in this paper i) we provide much

more details for all considered aspect; ii) we consider an

improved solution for the wrench estimate that exploits also

the linear acceleration measurements provided by the IMU;

iii) the position and force tracking quality has been largely

improved; iv) the physical property shaping capabilities of

the admittance filter are thoroughly tested and explained

and v) a very broad range of experiments is performed and

discussed; in particular, the case of sliding on a surface

with a tilted orientation, the peg-in-hole experiment, and the

admittance shaping tests and sliding in contact with two

ledges have been conducted.

Concluding this introduction, in the following we

summarize the main contributions (but not all) of this work:

1) we propose and show the practicability through real

experiments, of a completely new aerial physical interaction

paradigm: the 6D flying end-effector. We believe that this

Preprint, final version at https://journals.sagepub.com/loi/ijra Accepted for The International Journal of Robotics Research 2019

6D Interaction Control with Aerial Robots: The Flying End-Effector Paradigm 3

Figure 1. The Tilt-Hex (NCFTP aerial platform with tilted

propellers in-house developed at LAAS-CNRS) with the rigidly

attached end-effector. Notice how the interaction takes place far

away and off-centered from the vehicle CoM. The picture is

taken right after a Peg-In-Hole task was successfully performed.

paradigm will pave the way to a novel aerial system concept

which outperforms currently adopted solutions for aerial

manipulation and physical interaction in terms of capability,

reliability, complexity and costs.

2) we propose a specific integration of known robotic

algorithms, achieving both motion and interaction control

as well as external wrench estimation, in a thoroughly

conceived architecture and show how the integrated system

can work with a minimal sensor suite (pose sensor plus IMU)

not even needing a force sensor in its basic configuration

– the addition of more sensors, if available, being anyway

straightforward.

3) in support of the aforementioned features, we show

experiments that are the first of their kind in aerial robotics:

fully impedance shaping in 6D, peg-in-hole with tilted

holes, sliding on tilted surfaces. Moreover, in order to

show the effectiveness of the wrench estimate, a forth

experiment, consisting on sliding in contact with two ledges

on a surface mounted on an ATI45 force/torque sensor, has

been conducted in such a way to exert variable forces and

torques on the end-effector. The wrench estimator results

are compared with the measures obtained by the sensor. The

experiments are designed to clearly show the versatility and

the robustness of the proposed approach to the environmental

uncertainties.

The paper is organized as follows. First a generic model

for NCFTP aerial systems is introduced and afterwards we

model the proposed NCFTP platform, named Tilt-Hex. Then

the complete admittance control framework is presented as

well as its components, namely the inner loop geometric pose

controller, the wrench observer and the outer loop admittance

filter. Then we present the hard-/software architecture and the

experimental evaluation. Finally, we conclude the paper with

a summary of the results and an outline of future works.

Remark It is important to mention that the theory and the

architecture proposed in this paper is very general and works

seamlessly with any NCFTP platform other than the one used

in particular here.

System Modeling

We consider as aerial robot a fully actuated aerial vehicle

equipped with an arbitrarily mounted end-effector tool. The

presented physical interaction framework is generic for any

fully actuated system able to track a full-pose trajectory

with the end-effector. We shall start with the generic parts

of the modeling and present afterwards the instantiation of

this general model for the NCFTP hexarotor used in the

experiments.

General Modeling Let us consider the following coordinate

frames (see Figure 2):

• Inertial world frame F

W

, whose axes (unit vectors)

and origin are indicated with {x

W

,y

W

,z

W

} and O

W

,

respectively;

• Body frame F

R

: O

R

−{x

R

,y

R

,z

R

}, attached to the

robot and with origin O

R

in the CoM of the aerial

vehicle with the end-effector;

• End-effector frame F

E

: O

E

−{x

E

,y

E

,z

E

}, attached to

the robot end effector and with origin in the interaction

point O

E

.

For a generic vector υ, the notation υ

?

(with ? = R,E)

denotes that the vector υ is expressed in frame F

?

. If the

superscript is omitted it means that the vector is expressed in

inertial frame.

The position of O

R

expressed in F

W

is denoted by p

R

∈

R

3

, while the position of O

E

in F

W

and in F

R

are denoted by

p

E

∈R

3

and p

R

E

∈R

3

, respectively, where p

R

E

is constant over

time. Analogously, let us denote with R

R

∈ SO(3) and R

E

∈

SO(3) (where SO(3) = {A ∈ R

3×3

|AA

T

= I ∧ det A = 1})

the rotation matrices expressing, respectively, the orientation

of frame F

R

and F

E

with respect to the inertial frame F

W

.

Moreover, R

R

E

∈ SO(3) denotes the constant rotation matrix

expressing the orientation of F

E

with respect to F

R

. Finally

let us denote as ω

ω

ω

R

R

∈R

3

and ω

ω

ω

E

E

∈R

3

the angular velocities

of F

R

and F

E

with respect to F

W

expressed, respectively,

in frame F

R

and F

E

. Thus, the orientation kinematics of the

robot and the end effector are then expressed by

˙

R

R

= R

R

[ω

ω

ω

R

R

]

×

(1)

˙

R

E

= R

E

[ω

ω

ω

E

E

]

×

, (2)

respectively, where [•]

×

∈ SO(3) represents the skew

symmetric matrix (Siciliano et al. (2009)) associated to

vector •∈ R

3

.

Using the Newton-Euler formalism, the equation of

motion of the aerial robot can be expressed as

m

¨

p

R

J

˙

ω

ω

ω

R

R

= −

mge

3

ω

ω

ω

R

R

×Jω

ω

ω

R

R

| {z }

g(ω

ω

ω

R

R

)

+

f

τ

τ

τ

R

+

f

R

τ

τ

τ

R

R

(3)

where m and J ∈R

3×3

represent the robot mass and its inertia

matrix with respect to O

R

and expressed in F

R

, respectively,

g is the gravitational acceleration, f ∈ R

3

and τ

τ

τ

R

∈ R

3

are

force and torque inputs, while f

R

and τ

τ

τ

R

R

are the external force

and torque on the robot CoM due to the force and torque

exerted by the environment on the end-effector.

Preprint, final version at https://journals.sagepub.com/loi/ijra Accepted for The International Journal of Robotics Research 2019

4 Accepted for The International Journal of Robotics Research 2019

Figure 2. Schematic view of important frames and vectors of

the Tilt-Hex with the rigidly attached end-effector. The zoomed

propeller group shows further vectors needed to model the

system.

Remark It is worth noticing that, as usual in aerial robotics

field, in (3) the translational dynamics is expressed in the

frame F

W

, while the rotational dynamics is expressed in the

frame F

R

.

Tilt-Hex Without loss of generality for any fully actuated

aerial platform, we will now derive (3) for the NCFTP

platform used in the later presented experiments. The

NCFTP platform is based on a hexarotor structure, with

propellers equally-spaced and equidistant from O

R

in the

x-y-plane of F

R

. Full actuation is achieved by rigid

adapters, tilting every single motor-propeller combination

(see Figure 1 and 2). Let us consider 6 frames F

P

i

, i = 1 ...6

where O

P

i

coincides with the center of rotation of the i-th

propeller group (see Figure 2). The orientation of F

P

i

with

respect to F

B

is represented by the rotation matrix

R

R

P

i

= R

z

((i −1)

π

3

)R

x

((−1)

i−1

α)R

y

(β ), i = 1...6. (4)

The inclination of the i-th motor-propeller group with

respect to F

R

is defined by the constant parameters α and

β . The selection of α and β decides the maximum lateral

forces with the cost that higher lateral forces result in higher

internal forces and therefore a waste of energy (Rajappa et al.

(2015)). Selecting an alternating sign of α for every other

propeller in (4) allows for the full actuation of the aerial

vehicle.

The i-th motor-propeller group’s position with respect to

O

R

can be defined as

p

R

P

i

= R

z

((i −1)

π

3

)l +R

x

((−1)

i−1

α)R

y

(β )d, i = 1 ...6

(5)

where d is the vector from the center of the tilting rotation to

the center of the motor-propeller group O

P

i

, and l is the vector

from O

R

to the center of the tilting rotation (see Figure 2).

As well known, a spinning propeller generates a thrust

force and a drag moment in O

P

i

. In a good approximation

both can be modeled by utilizing the signed squared of the

spinning velocity as

f

R

i

= c

f

u

i

R

R

P

i

e

3

, i = 1 . . . 6 (6)

and

τ

τ

τ

R

i

= (−1)

i−1

c

τ

u

i

R

R

P

i

e

3

, i = 1 . . . 6 (7)

Table 1. Overview of most symbols used in this paper. If

constant through all experiments a value is presented as well.

Definition Symbol Value

Inertial world frame with origin O

W

and axes {x

W

,y

W

,z

W

} F

W

Robot body frame with origin O

R

and axes {x

R

,y

R

,z

R

} F

R

End effector frame with origin O

E

and axes {x

E

,y

E

,z

E

} F

E

Symbols that can assume the values W,R, or E ?, ◦

Position of O

◦

in F

W

p

◦

Velocity of O

◦

in F

W

v

◦

Rotation matrix expressing the orientation of F

◦

w.r.t. F

?

R

?

◦

Rotation matrix expressing the orientation of F

◦

w.r.t. F

W

R

◦

Angular velocity of F

◦

w.r.t. F

W

, expressed in F

◦

ω

ω

ω

◦

Reference position expressed in F

W

p

R,r

Reference rotation matrix R

R,r

Desired position expressed in F

W

p

R,d

Desired rotation matrix R

R,d

Actuation wrench expressed in F

W

w

Real external wrench on the EE in F

W

w

E

Observed (estimated) external wrench on the EE in F

W

ˆ

w

E

Observed (estimated) external wrench on the robot in F

W

ˆ

w

R

Tilting angle (around x

P

i

) of the i

th

prop. group α

i

35

◦

Tilting angle (around y

P

i

) of the i

th

prop. group β

i

10

◦

i

th

propeller blade spinning frequency about z

P

i

(in Hz)

√

u

i

Mass of the whole aerial robot m 2.4 Kg

Gravity acceleration constant g 9.81 m/s

2

Gain matrix of the wrench observer K

I

Mechanical impedance inertia matrix M

E

Mechanical impedance damping matrix D

E

Mechanical impedance stiffness matrix K

E

with c

f

and c

τ

being constant parameters linking the

propeller spinning velocity

√

u

i

to the generated thrust force

and drag moment. The term (−1)

i−1

in (7) represents the

effect of counter spinning rotors for all even propellers.

We can now express the total force applied on O

R

in F

W

as

f(u) = R

R

6

∑

i=1

f

R

i

= R

R

F

1

u (8)

with F

1

∈ R

3×6

incorporating the geometrical and physical

properties of the aerial robot (i.e., dimensions, tilting angles,

thrust coefficients) and with u = [u

1

...u

6

]

T

being the vector

collecting the 6 squared propeller spinning velocities.

In the same manner we can incorporate the total torque due

to the thrust contribution and the drag moment expressed in

F

B

utilizing (6) and (7) as

τ

τ

τ

R

(u) =

6

∑

i=1

(p

R

P

×f

R

i

+ τ

τ

τ

R

i

) = F

2

u (9)

where F

2

∈R

3×6

again includes the geometrical and physical

properties. A detailed derivation of the model and of F

1

and

F

2

and its necessary conditions for full actuation can be

found in Rajappa et al. (2015) and Michieletto et al. (2017).

By replacing (8) and (9) in (3) we obtain

m

¨

p

R

J

˙

ω

ω

ω

R

R

= g(ω

ω

ω

R

) +

R

R

F

1

F

2

u +

f

R

τ

τ

τ

R

R

(10)

as a reliable dynamical model under slow flight conditions

(< 0.5 m/s). We neglect any aerodynamic effects like the

well known first order-effects rotor drag, fuselage drag and

H-force as these effects linearly depend on the vehicle’s

velocity and can therefore be neglected for the slow velocity

aerial interaction considered in this paper (Faessler et al.

(2018); Kai et al. (2017)).

Preprint, final version at https://journals.sagepub.com/loi/ijra Accepted for The International Journal of Robotics Research 2019