Q2. What are the future works in "A 5-step reduced mechanism for combustion of co/h2/h2o/ch4/co2 mixtures with low hydrogen/methane and high h2o content" ?

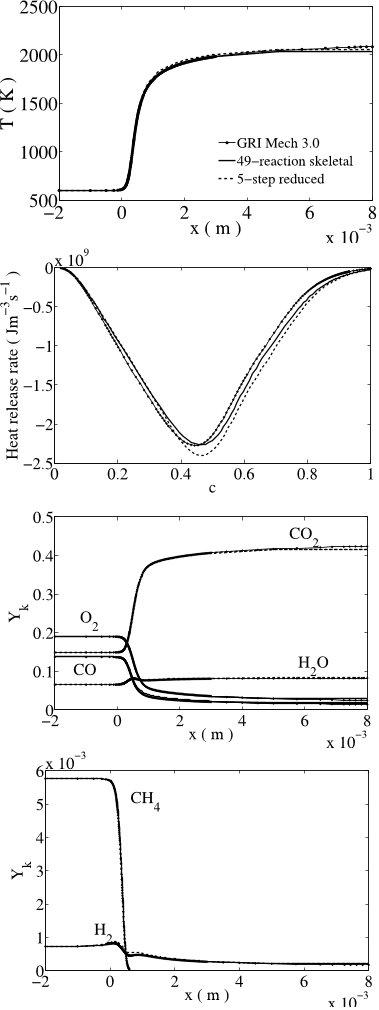

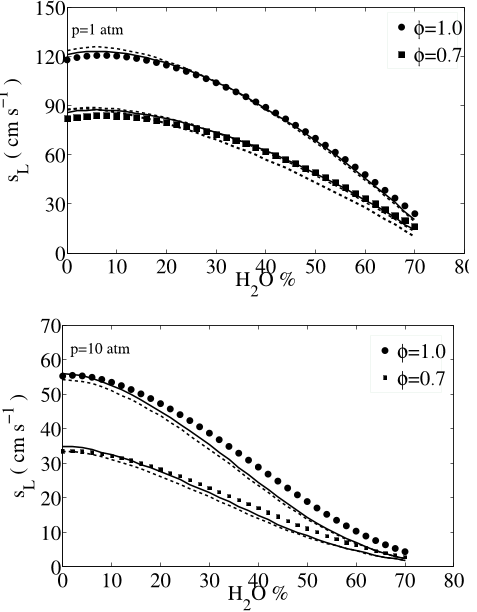

The computational results are compared to experimental measurements of the flame speeds available in the literature for a wide range of pressure, 1-20 atm., temperature, 298- 700 K and thermo-chemical conditions. The authors thank the reviewers for suggesting many validation data which helped to show the robustness of the mechanisms over wide range of conditions for flame speeds and autoignition delay times.

![Fig. 4: Laminar flame speeds of CO/H2-air mixtures using the reduced (dashed lines) and skeletal (full lines) mechanisms. Symbols: experimental results of Vagelopoulos and Egolfopoulos [48]. Tu = 298 K, p = 1 atm, XN2/XO2 = 3.76.](/figures/fig-4-laminar-flame-speeds-of-co-h2-air-mixtures-using-the-209eopff.png)

![Fig. 3: Laminar flame speeds of syngas mixtures ( CO/H2/CH4/CO2/N2-air ) using the reduced (dashed lines) and the skeletal (full lines) mechanisms. Symbols: experimental results of Yong et al. [27]. fCH4 = 0.24 with 11% CO2 and 42.7% N2 in the fuel mixture. Tu = 298 K, p = 1 atm, XN2/XO2 = 3.76. Error bars from [27] are also shown.](/figures/fig-3-laminar-flame-speeds-of-syngas-mixtures-co-h2-ch4-co2-3u6a11oi.png)

![Fig. 8: Laminar flame speeds of CO/H2 mixtures using the reduced (dashed lines) and skeletal (continuous lines) mechanisms. Symbols: experimental results of Sun et al. [33]. At p = 1 atm the oxidizer is O2,N2 with XN2/XO2 = 3.76. At p = 5, 10, 20 atm the oxidizer is O2 and He with XHe/XO2 = 7.0. Open symbols: experimental results of Singh et al. [21].](/figures/fig-8-laminar-flame-speeds-of-co-h2-mixtures-using-the-1l00yv4j.png)

![Fig. 22: Ignition delay times of CO/H2/CO2/O2/N2 mixtures using the reduced (dashed lines) and skeletal (continuous lines) mechanisms. Symbols: experimental data of [28], 8.91%H2 + 11.58%CO+ 24.44%CO2 + 10.25%O2 + 44.83%N2.62](/figures/fig-22-ignition-delay-times-of-co-h2-co2-o2-n2-mixtures-3pfqzjjf.png)

![Fig. 21: Ignition delay times of CO/H2/O2/N2 mixtures ( XN2/XO2 = 3.76) for φ = 0.5 using the reduced (dashed lines) and skeletal (continuous lines) mechanisms. Symbols: experimental results of Kalitan et al. [55]. Also shown for comparison are the results with the skeletal mechanism of Boivin et al. [14] (dashed lines with ×) for the fH2 = 20/80 case.](/figures/fig-21-ignition-delay-times-of-co-h2-o2-n2-mixtures-xn2-xo2-3newhz2i.png)

![Fig. 1: Laminar flame speeds of CO/H2/H2O-air mixtures using the reduced (dashed lines) and skeletal (full lines) mechanisms. Open circles: Li et al. [31] mechanism results from [22]. Also shown are the predictions using the skeletal mechanism of Boivin et al. (dashed lines with ×) [14]. Filled symbols: experimental results of Das et al. [22]. Tu = 323 K, p = 1 atm, fH2 = 5/95, XN2/XO2 = 3.76.](/figures/fig-1-laminar-flame-speeds-of-co-h2-h2o-air-mixtures-using-1wc6l9to.png)

![Fig. 2: Laminar flame speeds of CO/H2/H2O mixtures using the reduced (dashed lines) and skeletal (continuous lines) mechanisms. Filled symbols: experimental results of Singh et al. [21]. p = 1 atm, Tu = 400 K, φ = 1, oxidiser is O2,N2 with XN2/XO2 = 3.76.](/figures/fig-2-laminar-flame-speeds-of-co-h2-h2o-mixtures-using-the-twgf0oeg.png)

![Fig. 7: Laminar flame speeds of CO/H2/CO2/O2/N2 mixtures using the reduced (dashed lines) and skeletal (continuous lines) mechanisms . Symbols: experimental results of Natarajan et al. [49]. fH2 = 5/95 and 1.0, at p = 1 atm, XN2/XO2 = 3.76 with 10% and 20% CO2 dilution.](/figures/fig-7-laminar-flame-speeds-of-co-h2-co2-o2-n2-mixtures-using-3p13osby.png)

![Fig. 6: Laminar flame speeds of CO/H2 mixtures using the reduced (dashed lines) and skeletal (continuous lines) mechanisms. Filled symbols: experimental results of Singh et al. [21]. p = 1 atm, oxidizer is air.](/figures/fig-6-laminar-flame-speeds-of-co-h2-mixtures-using-the-2hspl2i9.png)

![Fig. 10: Laminar flame speeds of CO/H2/CH4/CO2/O2/N2 mixtures using the reduced (dashed lines) and skeletal (continuous lines) mechanisms. Symbols: experimental results of Park et al. [54], p = 1 atm, Tu = 298 K. 49](/figures/fig-10-laminar-flame-speeds-of-co-h2-ch4-co2-o2-n2-mixtures-1taf19bx.png)

![Fig. 5: Laminar flame speeds of CO/H2/O2/N2 mixtures using the reduced (dashed lines) and skeletal ( continuous lines ) mechanisms. Also shown are the results using the 4- step reduced mechanism of [14] ( open squares ), the skeletal mechanism of [14] ( open circles ) from the same study, and the implementation of the skeletal mechanism of [14] in this study (dashed-dotted lines). Symbols: experimental results of Natarajan et al. [49]. fH2 = 5/95 and 1.0, at p = 1 atm, XN2/XO2 = 3.76, for Tu = 400, 500, 600 and 700 K.](/figures/fig-5-laminar-flame-speeds-of-co-h2-o2-n2-mixtures-using-the-izelzdr2.png)