Q2. What future works have the authors mentioned in the paper "A calibration procedure for reconfigurable gough-stewart manipulators" ?

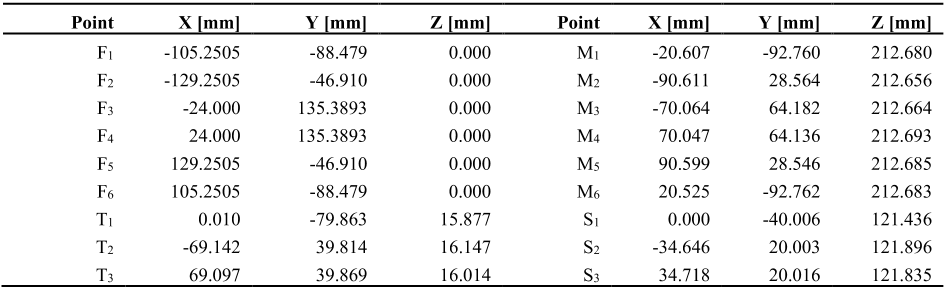

Since the procedure follows a linear approximation with the assumption of small parameter variation, it is possible to study the dependency of limb length on position and geometry independently. A direct derivation of the total differential of Eq. ( 2. 2 ) yields the same result without decoupling the system and can be obtained by expanding Eq. ( A. 5 ) without applying conditions ( A. 6 ) or ( A. 9 ).