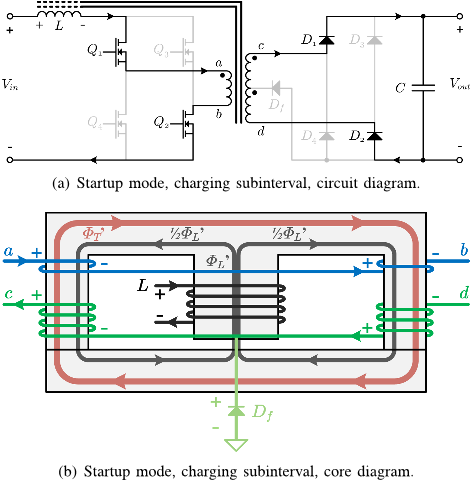

subinterval of operation is shown with an electric circuit

diagram followed by the corresponding and a magnetic core

diagram. Relevant voltage polarities are marked with +/-

signs, and current directions are marked with arrows while

inactive elements are dimmed. The electric circuit diagrams

correspond to their respective core diagrams by the ports

marked a, b, c, d. The core diagrams include the flux rate,

dφ

dt

= φ

0

, induced by the inductor, as well as the flux rate

induced by the transformer. The circuit operation can be

understood by analysing voltage polarities and flux rates

together with the right hand rule, while taking into account

the switch states, current directions and diode bias.

Boost mode operation (D

sw

≥ 0.5)

In the familiar isolated boost topology, the full-bridge

switch duty cycle must be above 0.5, such that there is always

a current path available for the boost inductor. This is defined

as the normal boost mode operation. The gate signal is

phase-shifted 180

◦

between each diagonal high-side/low-side

switch pair. Since D

sw

≥ 0.5, the phase shifted gate signals

overlap such that either all switches are on, or two diagonal

switches are on.

When all switches are on, V

in

is applied to the boost inductor,

and the input current is increasing. Known as the charging

or boosting subinterval, the circuit operation during this is

shown in fig. 4. As seen in fig. 4(b), the flux rate induced by

the inductor is uncoupled from the transformer windings due

to the fact that the voltage drops induced on the transformer

windings on each side leg are of opposite polarity.

The second sub-interval, referred to as the boost mode

discharge subinterval, is shown in fig. 5. When two diagonal

switches are on and the other two are off, the inductor

current passes through the primary winding, allowing the

corresponding diagonal diode pair of the output rectifier to

become forward biased. The output voltage is reflected to the

primary winding, such that a negative voltage drop is applied

over the inductor, decreasing the current. The corresponding

core diagram in fig. 5(b) shows that the inductor flux rate

is decreasing, and is still uncoupled from the transformer.

Additionally, it is noted that the flyback diode D

f

is reverse

biased.

Start-up mode operation (D

sw

< 0.5)

When the switch duty cycle is reduced below 0.5, the

diagonal switch pairs are no longer overlapping in on-state,

meaning that either two diagonal switches are on or all

switches are off. When two switches are on, the circuit

operation is identical to the boost mode discharge subinterval,

except that the inductor current is now decreasing due to the

fact that the primary voltage is lower than the input voltage,

causing a positive voltage drop over L. Because of this,

the subinterval is referred to as the start-up mode charging

subinterval, and the corresponding circuit and core diagrams

are seen in fig. 6.

(a) Boost mode, charging subinterval, circuit diagram.

(b) Boost mode, charging subinterval, core diagram.

Fig. 4. Boost mode, charging subinterval. All switches are on, inductor

current is increasing. Core diagram shows that inductor flux rate is decoupled

from transformer.

(a) Boost mode, discharging subinterval, circuit diagram.

(b) Boost mode, discharging subinterval, core diagram.

Fig. 5. Boost mode, discharge subinterval. Two diagonal switches are on,

inductor current is decreased by transferring energy through the transformer.

It is noted that D

f

is reverse biased..

When all switches are off, there needs to be an alternative

current path such that the inductor flux remains continuous

in order to avoid MOSFET avalanche mode clamping of the

stored energy. This current path is provided by the secondary

transformer winding, which thereby acts as a flyback winding

during the flyback discharge subinterval seen in fig. 7. During

switch turn off, the inductor current is decreasing, creating a