A novel strategy to enhance interfacial adhesion in fiber-reinforced calcium phosphate cement

Summary (2 min read)

Introduction

- Synthetic bone grafts, but their poor toughness limits their use to nonload-bearing applications.

- Reinforcement through introduction of fibers and yarns has been evaluated in various studies but always resulted in a decrease in elastic modulus or bending strength when compared to the CPC matrix.

- The aim of the present work was to improve the interfacial adhesion between fibers and matrix to obtain tougher biocompatible fiberreinforced calcium phosphate cements .

- This was done by adding a polymer solution to the matrix, with chemical affinity to the reinforcing chitosan fibers, namely trimethyl chitosan (TMC).

- Additionally the TMC-modified CPCs showed suitable biocompatibility with an osteoblastic cell line.

A novel strategy to enhance interfacial adhesion in fiber-reinforced calcium phosphate

- An improvement of the mechanical performance of these materials, and particularly a mitigation of their brittle behavior, would significantly extend the applicability of CPCs.

- For the last 15 years, several strategies have been evaluated to reinforce CPCs with fibers (Canal & Ginebra 2011; Krüger & Groll 2012).

- The excellent adhesion between the PMMA particles and the PMMA matrix is due to the chemical affinity between the liquid and the solid phase.

- Thus, the aim of this work was to develop a biocompatible fiber-reinforced CPC with improved mechanical properties using chitosan as common polymer in the matrix and in the fibers, with the hypothesis that having an additive of similar nature would increase the chemical interactions between matrix and fibers, which would in turn result in a higher toughness.

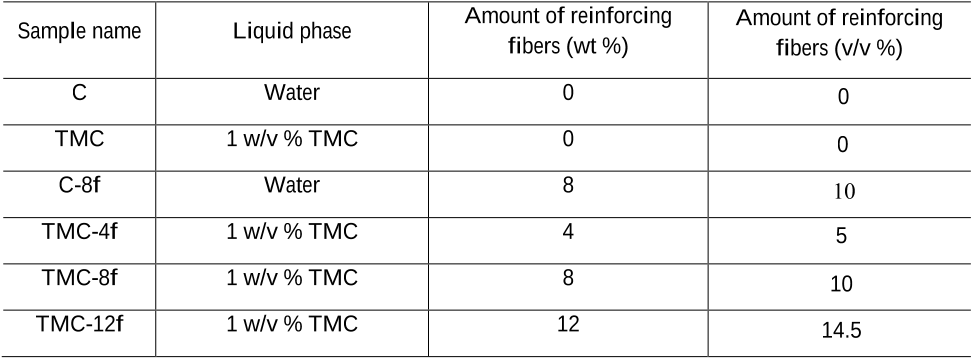

2.1 Fiber reinforced calcium phosphate cements

- Fiber-reinforced calcium phosphate cements were prepared by mixing a solid phase containing α-tricalcium phosphate (α-TCP) and chitosan fibers with a liquid phase.

- The solid phase consisted of in-house made α-TCP obtained by solid-state reaction of a 2:1 molar mixture of calcium hydrogen phosphate (CaHPO4, Sigma–Aldrich C7263) and calcium carbonate (CaCO3, Sigma–Aldrich C4830) at 1400 °C for 15 h followed by quenching in air.

- Detailed powder characteristics are described elsewhere (Espanol et al. 2009).

- To prepare FRCPCs, chitosan fibers were mixed with the CPCs powder.

- In all cases the specimens were set in Ringer’s solution (0.15 M sodium chloride solution) for 7 days at 37ºC.

2.2 Physico-chemical characterization

- The static contact angle of chitosan films with water or 1 w/v % TMC solution as wetting liquids was evaluated.

- It was not possible to measure the contact angle on CPCs –and their composites with chitosan fibers– due to their inherent microporosity and hydrophilicity.

- The assay consists in determining the time needed for the Gillmore needle to fail to make a perceptible circular indentation on the cement surface, counting as time zero the start of mixing.

- The cement’s phase composition was calculated with a semi-quantitative analysis (Chung 1974), which consisted in integrating the area of the three peaks with highest intensity and taking into account the reference intensity constant of their corresponding components.

- The specimens were tested in wet conditions, right after extraction from the setting liquid (ASTM 2008).

2.3 Biological characterization

- Pre-osteoblastic MG-63 cells (purchased from ATCC) were used to evaluate the effect of trimethyl chitosan modification of the cement matrix on the proliferation of the cells in direct contact with the materials.

- Afterwards the samples were rinsed in sterile PBS and pre-incubated for 1 h with supplemented media at 37°C.

- The absorbance values were transformed to cell number by using a standard curve.

- The number of viable cells was visualized after 1, 3 and 7 days using live/dead staining kit (Life Technologies, USA).

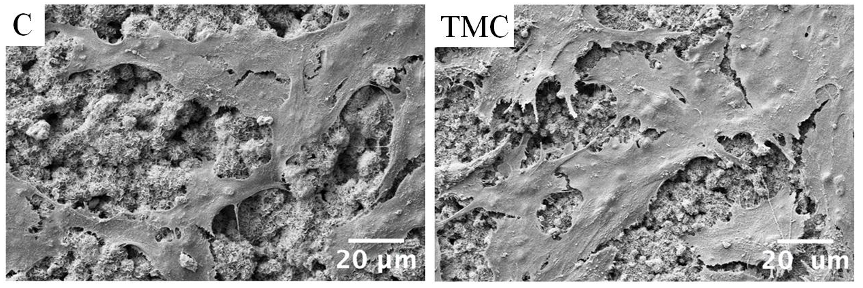

- The morphology of the MG-63 cells cultured on the cement specimens as well as the cement microstructures were visualized by Field Emission Scanning Electron Microscopy (FE-SEM, device: FIB Zeiss Neon40).

3. Results

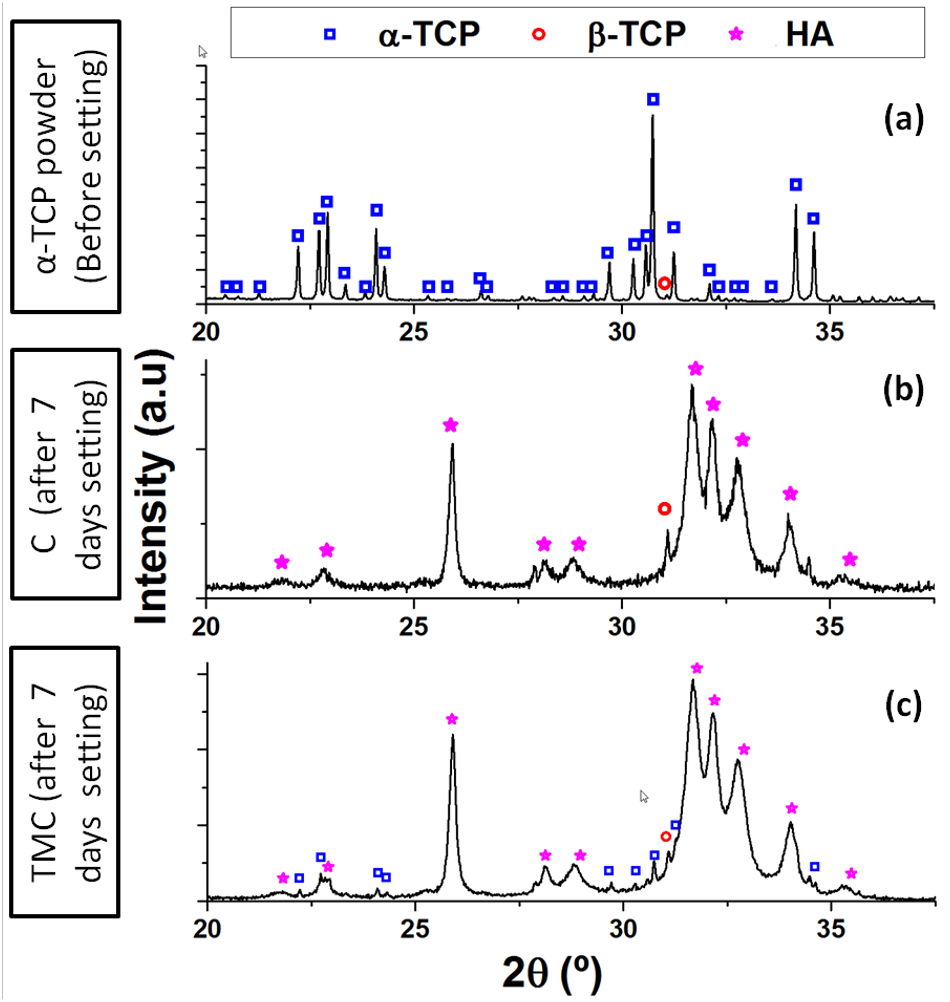

- The crystalline phases of the end-products of the cementitious reaction were analyzed after 7 days (Fig. 2, Table 3).

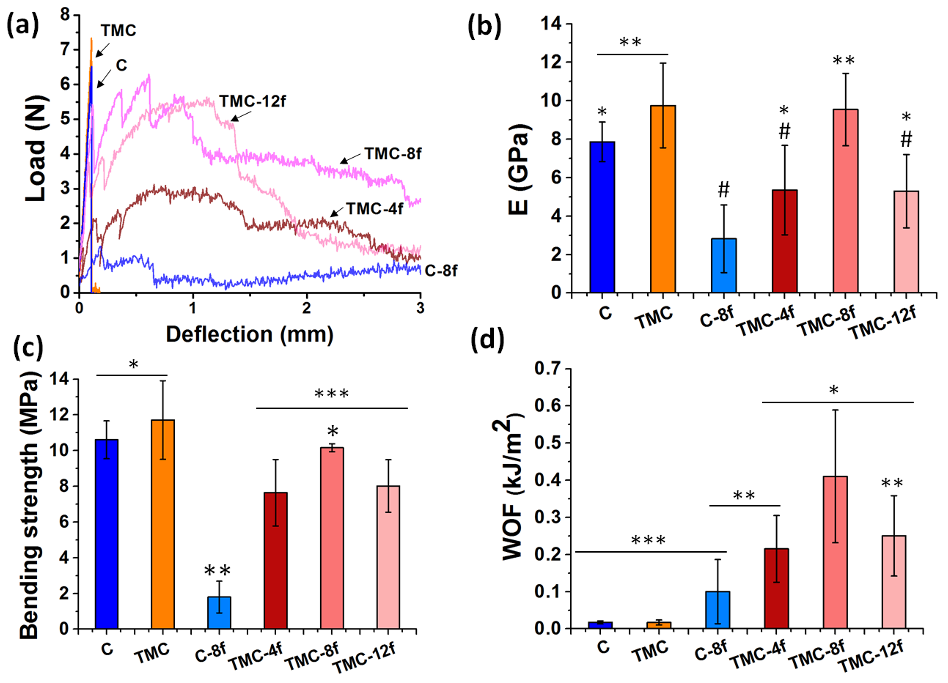

- The addition of TMC in the liquid phase did not modify the toughness (measured as WOF) of the samples without fibers (C ≈ TMC).

- Interestingly, the elastic modulus (Fig. 3b) of the cement containing both chitosan matrix and 8 wt% chitosan fibers (TMC-8f) was similar to that of a cement containing only TMC solution in the matrix, which highlights the relevance of adding TMC in the matrix to increase the fiber-matrix adhesion.

- The pH of the media in contact with TMC samples was hardly modified, especially after 2 days and on, being between 7 and 7.4 for all the samples (Fig. 5b), so this is not expected to influence cell adhesion or proliferation.

- The FRCPCs had a significantly improved toughness (measured as work of fracture) and at the same time the elastic modulus and bending strength were maintained in comparison to samples containing chitosan only as fibers or only as additive.

Did you find this useful? Give us your feedback

Figures (10)

Figure 2. Crystalline phases determined by X-ray diffraction of a) initial powder α –TCP, b) sample C 7 days after setting, and c) sample TMC 7 days after setting.

Figure 3. Mechanical properties under bending of unreinforced CPCs (C and TMC) and fiberreinforced CPCs (C-8f, TMC-4f, TMC-8f, TMC-12f): a) Typical load/deflection curves, b) Young’s modulus (E), c) bending strength, and d) work of fracture (WOF). Groups indicated with same symbol do not have statistically significant differences (p > 0.05).

Figure 7. SEM images showing the morphology of cells cultured on C and TMC samples for 7 days.

Figure 6. Live/dead images showing the alive cells (green) and the dead cells (red) on the C and TMC samples surface at different time points (bar = 100 μm)

Figure 5. a) Number of cells adhered on the samples surface at different time points, and b) evolution with time of the pH of the cell culture medium (1 ml) in contact with a cement disc (15 mm diameter x 1.5 mm thickness).

Table 3. Crystalline phases as determined by X-ray diffraction, and specific surface area measured by N2 adsorption of the initial powder and set cements.

Figure 4. Microstructure taken by FE-SEM of the fracture surface of unreinforced cements and of FRCPCs set for 7 days: C (a), TMC (b), C-8f (c, e, g) and TMC-8f (d, f, h).

Figure 1. pH of α-TCP powder slurries (200 g/ml) in MilliQ water or in 1 w/v% TMC solution measured continuously at 37°C.

Table 1. Nomenclature used for the samples according to the liquid phase used and the presence of reinforcing fibers.

Table 2. Setting time and compressive strength of CPCs using as liquid phase pure water (C) or 1% w/v TMC in water (TMC). Different letters indicate statistically significant differences (p < 0.05) between C and TMC for each group (initial setting time, final setting time and compressive strength).

Citations

10 citations

Cites background from "A novel strategy to enhance interfa..."

...However, the amide C=O bond and amide C-N bond shift to 1,537 cm-1 and 1,648 cm-1, respectively, for tSF, implying a random form of SF chains.(30) These results indicate that the secondary structure of SF changes after treatment with the calcium hydroxide solution....

[...]

10 citations

7 citations

6 citations

6 citations

Cites methods from "A novel strategy to enhance interfa..."

...The work of fracture (WOF) is calculated according to the method in a previous study [27]....

[...]

References

558 citations

"A novel strategy to enhance interfa..." refers methods in this paper

...The cement’s phase composition was calculated with a semi-quantitative analysis (Chung 1974),...

[...]

...The cement’s phase composition was calculated with a semi-quantitative analysis (Chung 1974), which consisted in integrating the area of the three peaks with highest intensity and taking into account the reference intensity constant of their corresponding components....

[...]

425 citations

"A novel strategy to enhance interfa..." refers background in this paper

...The toughness of CPCs ranges from 0.010-0.050 kJ/m 2 in their work of fracture (WOF) (Canal & Ginebra 2011), which is far below the work of fracture of bone, reported to be between 1.5 and 15 kJ/m 2 (Currey & Butler 1975)....

[...]

...Notwithstanding, the value obtained for TMC-8f (0.4 kJ/m 2 ) is still lower than the WOF described for cortical bone, which has been reported to range between 1.5 and 15 kJ/m 2 (Currey & Butler 1975)....

[...]

334 citations

"A novel strategy to enhance interfa..." refers background in this paper

...Among the different polymers, chitosan is of interest mainly because it is biodegradable, biocompatible, and it can be processed into several products including flakes, fine powders, beads, membranes, fibers, and gels (Badawy & Rabea 2011)....

[...]

217 citations

"A novel strategy to enhance interfa..." refers background in this paper

...derivative (Domard et al. 1986), was added to the cement liquid phase, and chitosan fibers were...

[...]

...As chitosan is poorly soluble in water, trimethyl chitosan (TMC), which is a more soluble chitosan derivative (Domard et al. 1986), was added to the cement liquid phase, and chitosan fibers were used as reinforcing agents....

[...]

217 citations

"A novel strategy to enhance interfa..." refers background in this paper

...These approaches have allowed either an increase of the mechanical properties (Zhang & Xu 2005) or to couple good mechanical properties and macroporosity, increasing the degradation rate and allowing cell infiltration in the material (Xu et al. 2006; Xu et al. 2007)....

[...]