HAL Id: hal-00098361

https://hal.archives-ouvertes.fr/hal-00098361

Submitted on 16 Feb 2018

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of sci-

entic research documents, whether they are pub-

lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diusion de documents

scientiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Prediction of the machining defects in ank milling

Arnaud Larue, Bernard Anselmetti

To cite this version:

Arnaud Larue, Bernard Anselmetti. Prediction of the machining defects in ank milling. International

Journal of Advanced Manufacturing Technology, Springer Verlag, 2004, Vol. 24/1-2 (1), pp. 102-111.

�10.1007/s00170-003-1774-z�. �hal-00098361�

A. Larue, B. Anselmetti

A prediction of the machining defects in flank milling

Abstract In peripheral milling with great axial engage-

ments, the tool deflections generate some geometrical

defects on the machined surface. This article present a

prediction method of these defects which is applicable

on every ruled surface. The cutting forces are estimate

with the cutting pressure notion. The parameters of the

tool/workpiece material couple are identified by a test

part. The prediction of the tool deflections requires

controlling the tool immersion angle for each angular

position of the tool. The deflections can be significant.

An original procedure which is based on an engagement

cards avoids an iterative calculation of the radial

engagement. The experimental checking of the method

of prediction is presented in a test.

Keywords Peripheral milling Æ Tool deflections Æ

Identification of a tool workpiece material couple Æ

Engagement cards

1 Introduction

1.1 Prese ntation

The present stud y is about flank milling using the long

cutters of free forms. This free forms are made up of

ruled surfaces. This very powerful process, from a pro-

ductivity and surface quality point of view, is very

popular in aeronautics and mould manufacturing.

The magnitude of the defect induced by the deflection

of a long HSS cutter with a diameter of 20 mm can reach

0.7 mm for a radial engagement of 3 mm. Such geo-

metrical variations induce the nonrespective of the part

specifications.

The purpose of this article is to establish a prediction

method of flank milling defects at low speeds which can

be integrated in a computer aided sesign and manufac-

turing software (CAD/CAM).

The characterisation of the tool deflections is based

on a cutting pressure model. The model parameters are

gauged by milling a test part on the production machine

tool. When the tool workpiece coupl e is identified, the

influence of the tool deflection on the part geometrical

defects can be predicted.

1.2 The problem

To predict tool deflection, it is necessary to control the

engagement of the cutting edges into the workpiece

material at every moment.

At high cutting speed, chatter vibration phenomena

appears [1, 2]. To model that phenomena, lots of re-

search took the mass, the damping and the acceleration

of the milling structure into account [3, 4, 5, 6]. These

studies allow the prediction of the vibratory behaviour

of the structure. First ly, they result in long calculations

which are difficult to implement in a CAD/CAM system

on all the surfaces to machine. Secondly, such studies

require a dynamical protocol to identify the dynamical

structure characteristics and the force model parameters.

Our objective at low speed milling was to predict the

surface defects and to compensate for the tool paths. We

also needed a model whic h was easy to identify and fast

to use. We showed that a satisfying result can already be

obtained without taking the vibratory behaviour into

account [7]. That’s why the calculation of surface defects

thus passes by the motion study of the generating point

of each cutting edges in catch in the workpiece material.

In fact, the surface is generated by the cutter sweep-

ing. Each rule of the surface is obtained by the gener-

ating point displacement along the helicoidal cutting

edge during the rotation of the cutter.

A. Larue (&)

LURPA Ecole Normale Supe

´

rieure de Cachan,

61 Av Pt Wilson, 94235 Cachan Cedex, France

E-mail: larue@lurpa.ens-cachan.fr

Tel.: +33-1-47402765

Fax: +33-1-47402220

B. Anselmetti

Institut Universitaire de Technologie de CACHAN,

9 avenue de la division, Leclerc 94234 Cedex, France

1

The tool deflection can be calculated at every moment

using a model resulting from the materials resistance

theory (RdM).

The cutting forces applied to the tool thus depend on

the number of teeth in catch and on the length of the

cutting edge engaged in the workpiece material at every

moment.

It is thus necessary to calculate the immersion angles

for each cutting edge starting from the finished surface

and from the rough surface defined by the CAD model.

This calculation must be carried out for each rule and

for each angular position of the cutt er.

During our tests, we have showed that the deflections

are so significant that it is absolutely necessary to take

the deflection into account to calculate the cutting edge

engagement. In the first approach, this analysis requires

considering an iterative calculation process which is very

expensive in terms of computation times. The article’s

purpose is to establish a precise process, which avoids

this iterative calculat ion in the majority of the cases. It

presents the engagement card concept which represents

the tool load during the milling.

2 The modelisation of surface defects

2.1 The surface generation

The problem studied is the peripheral milling of a ruled

surface. Our interest is focused on the down milling case.

At first approximation, the tool path is generated so that

during that time, the cutter generatrix is combined with

the various rules of the surface. However, the surface

concavity is not constant along the rule. Various tech-

niques of the cutter axis shifting make it possible to

improve the milling quality by limiting the undercut and

the overcut [8, 9, 10, 11].

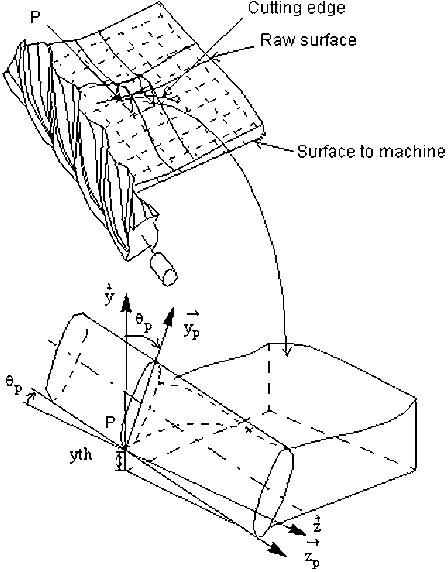

This work thus considers that the CAM system

constructs the tool path generation and gives the tool

axis (axis ~z position A

n

and the normal to the machined

surface

~

y at every moment, which makes it possible to

define the cutting section S

n

at the curvilinear abscissa

S

a

n

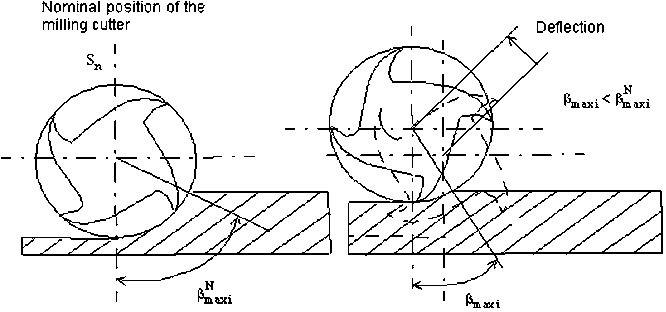

along the directrix (Fig. 1).

~

x completes the trihedral

~

x,

~

y, ~z in the feed direction.

In this section, we will suppose that the generatrix to

machine is the line D

n

. Our objective is thus to determine

the variations of the machined surface position com-

pared with the theoretical line D

n

. These variations are

added to the undercut and overcut defects. The different

sections will be studied with a ‘‘normal’’ step and a

‘‘reduced’’ step. The reduced step will be used when

some engagement discontinuities are detected on the

machined surface or on the rough surface.

The generating point of a tool is mobile on the line

D

n

. At moment t, the generating point is in P at distance

z of the tool holder which is supposed to provide a

perfect embedding. It is thus necessary to know the tool

deflection in P which will be equal to the surface position

variation in this point.

At moment t+dt, the generating point is in P’ at the

distance z’ (Fig. 2).

The deflection varies according to the generating

point P, which generates a deformed profile on the

surface.

2.2 The deflection model

Our deflection model correspond to an extension of the

Kline and DeVor model [12], which has involved lots of

semi static models [13, 14, 15].

At a given moment, the generating point is in P. Each

elementary length of the cutting edges in catch in the

workpiece generates an elementary tool deflection in

P. The sum of these deflections gives the variation of the

surface in P.

At point Q located along the cutting edge, the

angular position is b. The force applied in Q on a part of

the cutting edge, whose elementary length is dz, consists

Fig. 1 The place of the generating points

Fig. 2 The evolution of the generating point of a tool

2

of a tangential compone nt dFt and a radial component

dFr.

The cutting forces are obtained with the following

model:

dFr ¼ Kr ep dz ¼ Kr

0

fz sin bðÞdz

=

fz sin bðÞðÞ

0:3

ð1Þ

ep is the depth of cut given by: ep ¼ fz sin bðÞ.

fz is the feedrate per tooth.

Kr ¼ Kr

0

ep

0:3

and Kt ¼ Kt

0

ep

0:3

ð2Þ

The cutting pressures Kr

0

and Kt

0

are characteristics

of the tool workpiece material couple. They are deter-

mined by an identification test.

Only the normal component dN of the cutting force

acts on the mac hined surface deformation (Fig. 3):

dN bðÞ¼dFr bðÞcos bðÞþdFt bðÞsin bðÞ

In P, the resulting deflection dy induced by the force

dN appl ied to point Q is given by a simple model of a

fixed beam of the constant quadratic moment of inertia:

I

Gy

(Fig. 3).

dy ¼

1

E I

Gy

dN bðÞ

z L bðÞðÞ

3

3

!

þ

z L bðÞðÞ

2

L bðÞ

2

!"#

ð3Þ

where L bðÞ

¼h b

=

2pðÞis the distance between P and

Q for the tooth which leaves its trace on the part, h being

the helicoidal milling cutter step.

A similar relation is defined for the points Q which

belong to the following cutting edge in catch (when Q

is on the left of P).

For each point P, the theoretical total deflection is the

sum of the elementary deflections generated by all the

points Q of the cutting edges simultaneously engaged in

the workpiece material.

yth ¼

X

Nc

k¼1

Z

b

maxi

b

mini

dy

k

0

B

@

1

C

A

ð4Þ

where Nc is the number of cutting edges in catch.

The difficulty of the calculation lies in the definition

of the maximal and minimal immersion tool angles

(b

maxi

and b

mini

). The se angles are defined by the inter-

section of the screw which characteri ses the tool cutting

edge when the generating point is in P. b

maxi

corre-

sponds to the intersection with the rough surface. b

mini

corresponds either to the intersection with the finished

surface (b

mini

=0), or to the intersection with the side

of the part 06b

mini

6b

maxi

ðÞ. This calculation will be

developed in pa ragraph 4, because it should take the

tool deflection into account. Figure 4 shows the calcu-

lation of the resulting deflection dy at point P.

2.3 The identification of the coefficients

To determine the coefficients Kr

0

and Kt

0

, an identifi-

cation protocol on an unspecified industrial milling

machine was proposed [7, 16, 17]. The identification

procedure consists in the down peripheral milling of a

plan starting from the test part defined in Fig. 5. The

width of the part is slightly higher than

h

Z

where h is the

tool helicoı

¨

dal pitch and Z is the total number of teeth.

The radial depth of cut varies gradually from 0.5 to

3 mm (Fig. 5). The tool end is left free so as to make it

possible to stud y only the influence of the helicoidal

cutting edge on the part defect.

From an operational point of view, the identification

procedure consists in milling the test part and measuring

the defects of the machined surface.

The immersion angles can be calculated by taking the

tool deflection which is estimated starting from the

measured dots into account.

The coefficients Kr

0

and Kt

0

are calculated by mini-

mising the sum of the squares of the differences between

the dots measured and the dots simulated.

Fig. 3 The deflection model definition Fig. 4 The calculation of the resulting deflection dy at point P

3

2.4 The identification of the tool workpiece material

couple

For our application, the conditions of the identification

test are the following:

HSS tool of diameter 20 mm, whose active length is

88 mm—4 teeth:

– Machined workpiece material: C48

– Milling on a vertical milling centre

– Vc=25 m/min

– fz=0.2 mm/tooth

With I

Gy

=7,854 mm

4

, the coefficients calculated are:

Kr

0

¼ 312

Kt

0

¼ 120

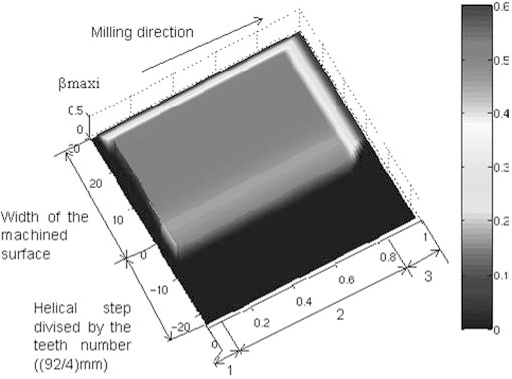

The simu lated machine surface is illustrated in Fig. 6.

Several tests showed that these coefficients are almost

independent from the cutting speed.

Figure 7 shows that the difference between the sim-

ulated and the cloud of theoretical dots lie for 95 percent

of the surface between ±0.05 mm.

3 The prediction of the milling defects in CAM

3.1 Introdu ction

The work objective is to predict the form and the posi-

tion variations of the flank machined surfaces. These

variations are due to the too l deflections generated by

the variable cutting forces. The part deformations and

the machine deformations are not taken into account.

These cutting forces are depending on the cutter

immersion angle at every moment which also consider-

ably depends on the tool deflection, which makes the

calculation difficult (Fig. 8).

In front of this problem, we propose a defects pre-

diction method which is applicable in a CAD environ-

ment for the milling of an unspecified ruled surface. The

final geometry to obtain is thus defined by a CAD

model. The tool paths are initially given by the CAD for

example with the use of tool laying techniques on a

surface, suggested by Rubio [8], To

¨

nshoff [9] and

Affouard [10].

By misnomer, we call the ‘‘rough’’ surface of the part

the part surface before the tool passes. This raw part can

be described by a CAD model or by a raw management

dynamical system according to the tool paths during the

preceding operations (NCSIMUL software [18], Vericut

software [19] and Delmia software [20]). In all cases, the

radial engagement is supposed to be lower than the

cutter diameter: ap £ 2·R, in order to exclude the mill-

ing in full matter.

3.2 The prediction algorithm in steady mode

An iterative solution would firstly consist in calculating

the cutter deflection by considering the theoretical angle

Fig. 5 The part for the calibration of the tool workpiece material

couple

Fig. 6 A simulation of the machined surface

Fig. 7 A comparison of the simulated and machined surfaces

4