Q1. What have the authors contributed in "Application of constitutive models in european codes to rc-frc" ?

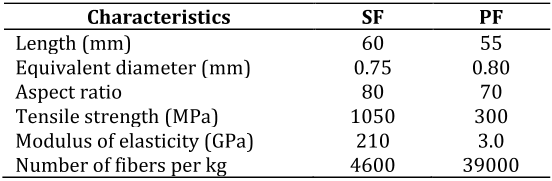

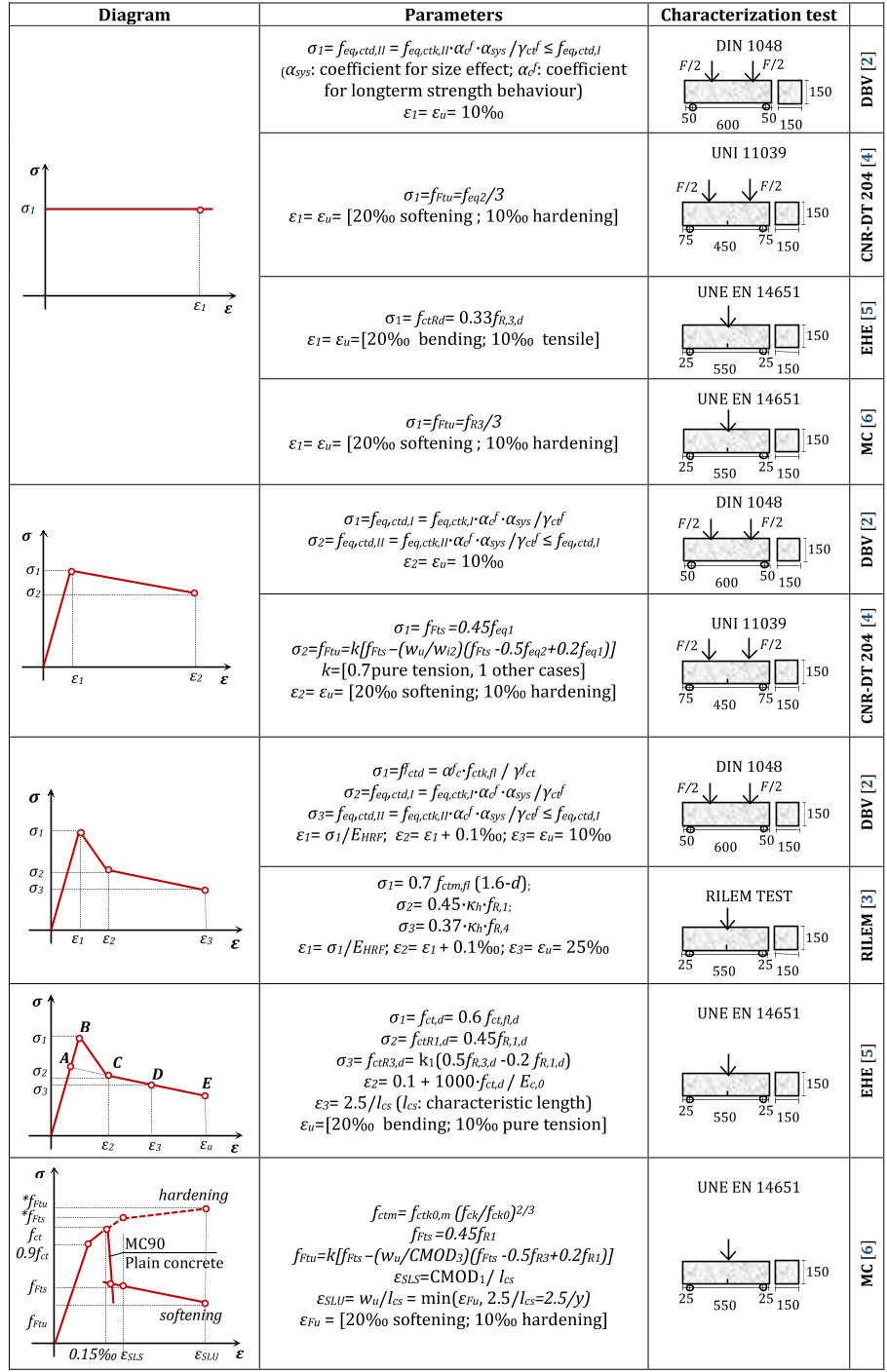

In this study, these models are compared and a numerical simulation is performed to evaluate their differences in terms of the structural behavior predicted and measured in an experimental program of RC-FRC elements. The predictions provided by the models fit satisfactorily the experimental results for elements with steel fibers and with plastic fibers

![Fig. 1. Constitutive models (σ-ε) for the characterization of the tensile behavior of FRC [20, 22, 23].](/figures/fig-1-constitutive-models-s-e-for-the-characterization-of-1cyfwrf0.png)

![Fig. 2. Constitituve models (σ-w) for the tensile behavior of FRC [24-27].](/figures/fig-2-constitituve-models-s-w-for-the-tensile-behavior-of-1x4c1124.png)

![Fig. 3. Constitutive models (σ-w) for the tensile response of FRC [28 and 15].](/figures/fig-3-constitutive-models-s-w-for-the-tensile-response-of-1kap3mod.png)