Q2. What are the major building blocks of lignocellulosic biomass?

There are three major building blocks of lignocellulosic biomass namely; hemicellulose, lignin and cellulose, but also minute quantities of other components.

Q3. What are the main advantages of acid pretreatment?

The various chemical pretreatment types applied before anaerobic digestion in biogas production include; acid pretreatment, alkaline pretreatment, wet oxidation, catalysed steam explosion, oxidative pretreatment with peroxides and the use of ionic liquids.

Q4. Why did the biomass production from untreated straw last longer?

Biogas production from untreated straw lasted for fewer days probably because there were lower amounts of reducing sugars available for the bacteria to feed on.

Q5. Why is the production of 2nd generation biofuels not very fruitful?

The production of 2nd generation biofuels is generally not very fruitful because of the necessity of pretreatment due to the presence of lignocellulose which adds to the operating cost, cost of transportation of feedstock and the acquisition of capital equipment.

Q6. What are the main types of biofuels?

Biofuels generally refer to compact materials (such as wood chips, pellets etc.), fluids like oils, biodiesel and ethanol, or gaseous fuels such as biohydrogen, biogas, and biosyngas that are mainly obtained from biomass sources (Cecilia Sambusiti 2013).

Q7. What was the effect of the heat assisted acid pretreatment on maize straw?

heat assisted acid pretreatment proved to be more effective especially for maize straw because test samples treated with acid without the application of heat failed to produce biogas probably because of a decrease in pH.

Q8. What countries have successfully implemented industries that process and produce first generation biofuels?

The US, EU and other developing countries like China, Brazil, Thailand, Colombia and Indonesia, have successfully implemented industries that process and produce 1st generation biofuels like bioethanol and biodiesel.

Q9. What is the rate of hydrolysis in lignocellulosic biomass?

If the enzymes do not have access to the substrate (the case in lignocellulosic biomass) hydrolysis becomes the rate-limiting step (Karimi 2008).

Q10. What are some examples of heavy metals that can cause disturbances in biogas plants?

Examples of heavy metals that can lead to disturbances in biogas plants are copper, nickel cadmium, zinc (Dieter D. and Angelika S. 2008).

Q11. How many stages of biogas production are involved in the anaerobic digestion process?

The anaerobic digestion process is complex and includes a wide range of microbes acting in up to nine stages of transformation of organic matter.

Q12. What is the main merit of using microalgae as a substrate for biofuel?

Major merits of using microalgae as a substrates for biofuel6production is its enormous oil content (approximately 40% on dry matter basis).

Q13. How much maize straw is produced simultaneously?

Estimates show that in the production of 1 kilogram of corn grain, approximately one kilogram of maize straw is simultaneously produced (Koundinya, et al. 2017).

Q14. Why is there a step up in the efficiency of the biomethane production process?

due to the little or no lignin and hemicelluloses in algae biomass, there is a step up in the efficiency of the biomethane production process (Saqib et al., 2013).

Q15. What is the condition for acetogens to acquire the energy they need to survive and?

This means that the condition necessary for acetogens to acquire the energy they need to survive and grow is very low concentrations of hydrogen and as a result, they enter a symbiotic relationship with methane producing microorganisms which survive only in environments with high hydrogen partial pressure

Q16. How many different concentrations of sodium hydroxide solutions were applied on the biomass?

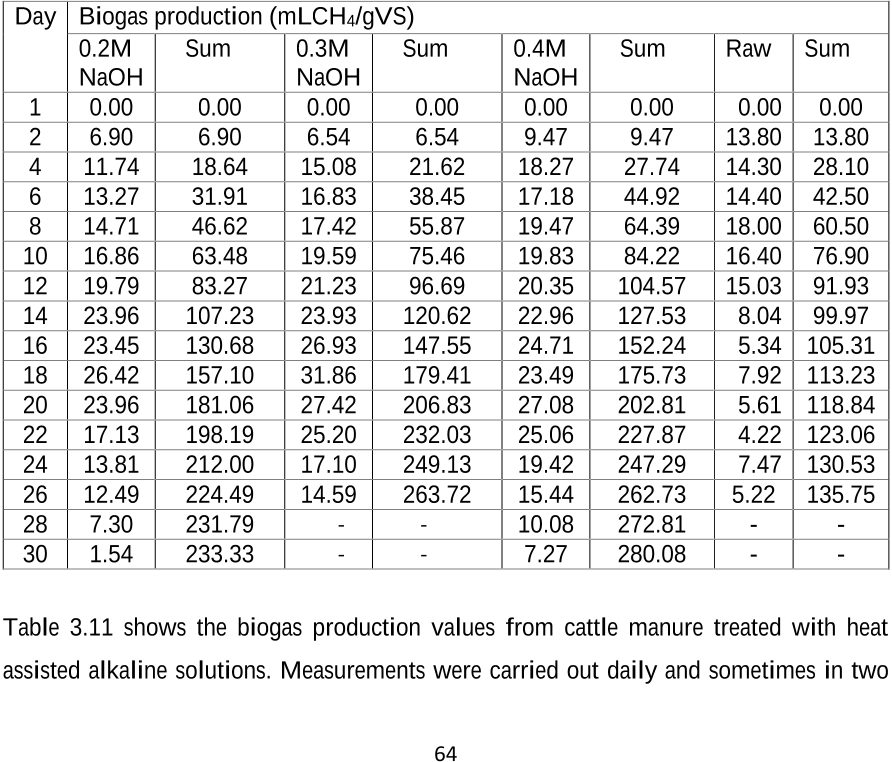

Three different concentrations of dilute sodium hydroxide solutions while heating in an autoclave at 120oC for thirty minutes were applied on the biomass.

Q17. What was the method used to determine the reducing sugar loads for the untreated and treated biomass?

The method used to determine the reducing sugar loads for both the untreated and treated biomass samples used in the study was the G. Lorenz Miller method (G. L. Miller 1959) using the Dinitrosalicylic acid reagent (DNS).

Q18. What is the average methane production from the pretreatment of cattle manure?

As seen above, the pretreatment condition which led to the maximum production of biomethane 0.3M acid solution with a total methane production value of 162.2mLCH4/gVS representing a 20% more methane production than the raw cattle manure.