Appl. Phys. Lett. 113, 243703 (2018); https://doi.org/10.1063/1.5064363 113, 243703

© 2018 Author(s).

Controlling shedding characteristics of

condensate drops using electrowetting

Cite as: Appl. Phys. Lett. 113, 243703 (2018); https://doi.org/10.1063/1.5064363

Submitted: 03 October 2018 . Accepted: 24 November 2018 . Published Online: 11 December 2018

Ranabir Dey, Jander Gilbers, Davood Baratian , Harmen Hoek, Dirk van den Ende, and Frieder Mugele

COLLECTIONS

This paper was selected as an Editor’s Pick

ARTICLES YOU MAY BE INTERESTED IN

Self-propelling Leidenfrost droplets on a variable topography surface

Applied Physics Letters 113, 243704 (2018); https://doi.org/10.1063/1.5056249

Investigation of Gilbert damping of a tetragonally distorted ultrathin Fe

0.5

Co

0.5

epitaxial film

with high magnetic anisotropy

Applied Physics Letters 113, 232406 (2018); https://doi.org/10.1063/1.5052721

Propensity for spontaneous relaxor-ferroelectric transition in quenched (Na

1/2

Bi

1/2

)TiO

3

-

BaTiO

3

compositions

Applied Physics Letters 113, 252902 (2018); https://doi.org/10.1063/1.5053989

Controlling shedding characteristics of condensate drops using

electrowetting

Ranabir Dey, Jander Gilbers, Davood Baratian, Harmen Hoek, Dirk van den Ende,

and Frieder Mugele

a)

Physics of Complex Fluids, MESAþ Institute for Nanotechnology, University of Twente, PO Box 217,

7500 AE Enschede, The Netherlands

(Received 3 October 2018; accepted 24 November 2018; published online 11 December 2018)

We show here that ac electrowetting (ac-EW) with structured electrodes can be used to control the

gravity-driven shedding of drops condensing onto flat hydrophobic surfaces. Under ac-EW with

straight interdigitated electrodes, the condensate drops shed with relatively small radii due to the ac-

EW-induced reduction of contact angle hysteresis. The smaller shedding radius, coupled with the

enhanced growth due to coalescence under EW, results in an increased shedding rate. We also show

that the condensate droplet pattern under EW can be controlled, and the coalescence can be further

enhanced, using interdigitated electrodes with zigzag edges. Such enhanced coalescence in conjunc-

tion with the electrically induced trapping effect due to the electrode geometry results in a larger

shedding radius, but a lower shedding rate. However, the shedding characteristics can be further opti-

mized by applying the electrical voltage intermittently. We finally provide an estimate of the conden-

sate volume removed per unit time in order to highlight how it is enhanced using ac-EW-controlled

dropwise condensation. Published by AIP Publishing. https://doi.org/10.1063/1.5064363

Dropwise condensation is important in a wide range of

technologies like water-harvesting systems,

1

desalination sys-

tems,

2

and heat exchangers.

3

The effectiveness of all these

technologies depends on the efficient volumetric collection

rate of the condensate and, hence, depends on the shedding of

the condensate drops from the condensing surface. The con-

tinuous drop shedding exposes the bare surface for renewed

nucleation and growth of the condensate drops culminating in

efficient vapour-to-liquid phase changes and enhanced con-

densate collection.

4

To this end, the enhanced mobility and

shedding of condensate drops have been studied on superhy-

drophobic nanostructured surfaces,

5–8

wettability-patterned

surfaces,

9

liquid impregnated textured surfaces,

10,11

and bio-

mimetic surfaces.

12

All these approaches towards enhancing

droplet mobility are passive in nature, relying solely on the

topographical and/or chemical patterning of the condensing

surface. As an alternative, recently we have demonstrated that

an alternating (ac) electric field in an electrowetting (EW)

configuration with structured electrodes can be used to

actively control the mobility of condensate drops on homoge-

neous hydrophobic surfaces.

13

The growth of the condensate

drops under EW is characterized by their migration to the

size-dependent locations of the minima in the corresponding

electrostatic energy landscapes and by enhanced coales-

cence.

13

The use of electrical forces to control condensate

droplet pattern (breath figures) evolution is—to our knowl-

edge—a completely new approach. While in our previous

study, we focused on the evolution and statistics of the con-

densate droplet pattern, the present work is devoted to the

analysis of subsequent gravity-driven shedding of condensate

drops under ac-EW. Such a study is essential for the effective

implementation of EW for technological applications involv-

ing dropwise condensation.

In this letter, we demonstrate that the gravity-driven

shedding characteristics of condensate drops can be indeed

controlled using ac-EW with structured electrodes. In gen-

eral, a condensate drop on a vertical substrate begins to shed

under gravity only when the drop reaches a certain critical

“shedding” radius R

sh

at which its weight overcomes the

inherent contact angle hysteresis force.

14

It has also been

demonstrated that ac-EW in air results in the reduction of the

effective contact angle hyste resis culminating in enhanced

mobilization of sessile drops.

15,16

We show here that under

ac-EW with straight interdigitated electrodes, the underlying

reduction in effective contact angle hysteresis and the

enhanced coalescence result in smaller R

sh

and the increased

shedding rate ðf

sh

Þ of the condensate drops, as compared to

the classical no EW case. Interestingly, the shedding charac-

teristics under ac-EW can be further altered using interdigi-

tated electrodes with zigzag edges. In this case, the enhanced

mobility of condensate drops due to the non-uniform electri-

cal force distribution and the eventual electrical trapping

effect result in larger R

sh

and lower f

sh

; however, the overall

condensate removal rate increases. Finally, we demonstrate

that the condensate shedding is further enhanced by applying

the electrical voltage intermittently instead of continuously.

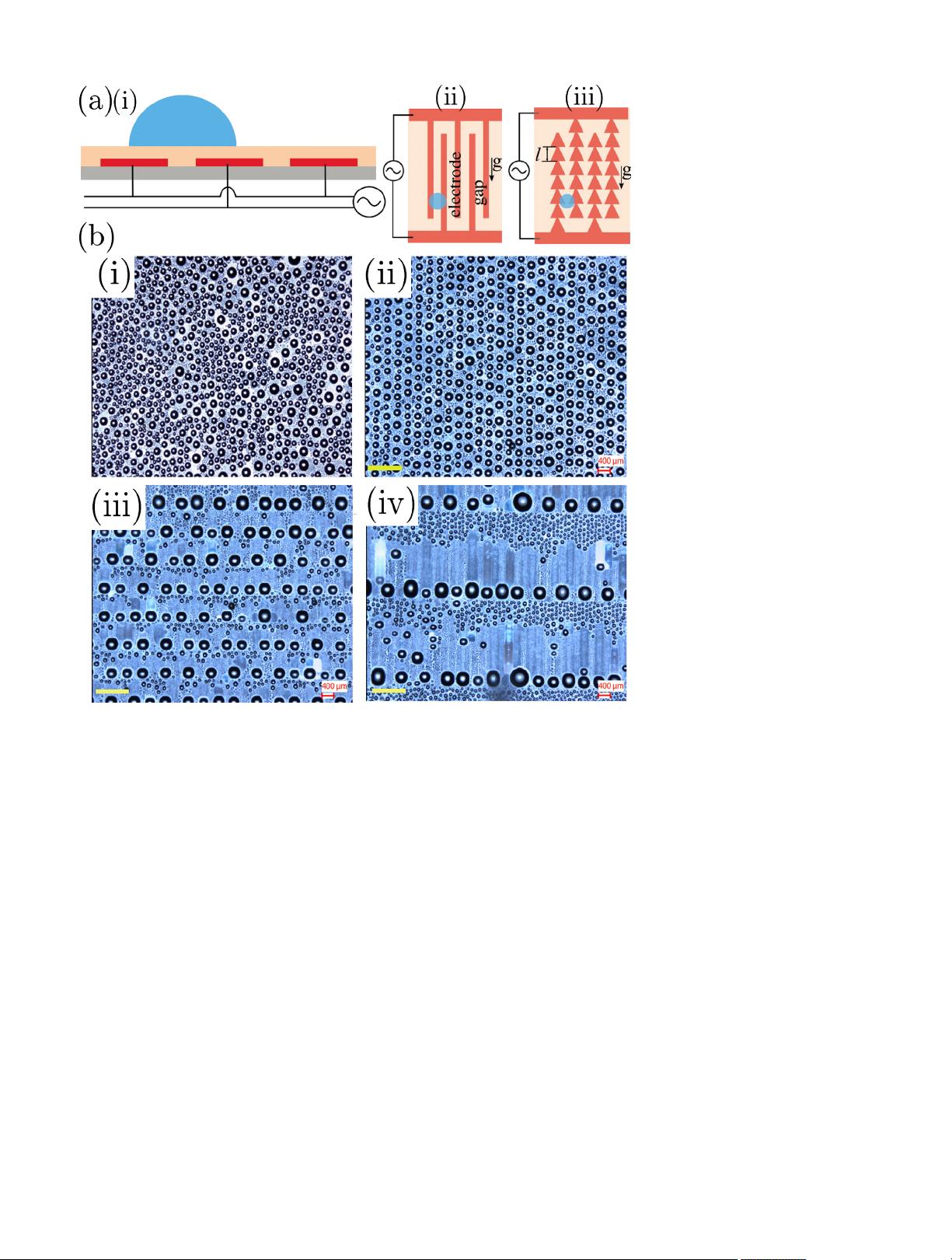

The experimental setup is identical to that used in our

previous study

13

(see Sec. S1 in the supplementary material

for a schematic). The condensing substrate [Fig. 1(a-i)] con-

sists of interdigitated ITO electrodes (red) on a glass sub-

strate (gray), which is coated with a hydroph obic dielectric

film (orange)—2 lm thick Parylene C layer topped with an

ultrathin layer of Cytop. For the straight interdigitated elec-

trodes [Fig. 1(a-ii)], the width of both the electrodes and the

gaps is 200 lm; for the zigzag interdigitated electrodes [Fig.

1(a-iii)], the base and the apex of each triangular element for

both electrodes and gaps are 250 lm and 50 lm wide, respec-

tively, while the distance l between the consecutive

a)

E-mail: f.mugele@utwente.nl

0003-6951/2018/113(24)/243703/5/$30.00 Published by AIP Publishing.113, 243703-1

APPLIED PHYSICS LETTERS 113, 243703 (2018)

triangular elements is varied from 500 lmto3000lm to cre-

ate different electrode designs. For EW, an ac voltage with a

frequency of f ¼ 1 kHz and a maximum magnitude of 150 V

U

rms

is applied across the electrodes [Fig. 1(a)]. Thereafter, a

stream of vapour-air mixture at a flow rate of 3.6 l/min and a

temperature of 41:8

C is passed through a condensation

chamber, in which the substrate is maintained at a temperature

of 11:5

C. Throughout the condensation process, the substrate

is kept inside the condensation chamber and the vapour-air

mixture flow rate is kept constant . Condensation experiments

are performed without EW and under ac-EW by applying dif-

ferent magnitudes of U

rms

using straight and zigzag interdigi-

tated electrodes with l ¼ 500 lm, 1000 lm, and 3000 lm. The

condensation process, including the shedding events, is moni-

tored for 5 min using a high resolution camera.

In the absence of EW (U

rms

¼ 0 V), the condensate drops

are apparently randomly distributed with smaller average

sizes [Fig. 1(b-i); Movie S1 in the supplementary material]. In

contrast, under ac-EW with straight interdigitated electrodes,

the condensate drops with diameters comparable to the gap

width are aligned along the corresponding electrostatic energy

minimum locations at the gap centres [Fig. 1(b-ii); Movie

S2]. As discussed in our earlier study,

13

this alignment pro-

cess is accompanied by a sharp increase in the average drop

size. The latter is caused by the cascades of coalescence

events triggered by the EW-induced migration of the drops.

In this study, the underlying fact that the coalescence-induced

growth of the condensate drops under EW can be further

enhanced by moving the drops in a particular direction using

non-uniform electrical forces motivated the use of the zigzag

interdigitated electrodes towards altering the final shedding

characteristics. The converging gap geometry results in a net

downward electrical force on a condensate drop which moves

it towards the gap apex. Such sweeping of condensate drops

results in enhanced coalescence culminating in increased

growth of the average drop size. However, the droplets thus

mobilized eventually accumulate at the apices of the triangu-

lar gap elements due to the electrical trapping effect at these

locations [schematic in Fig. 1(a-iii)]. Hence, the condensate

droplet pattern under EW with zigzag interdigitated electrodes

also has a periodicity along the electrodes which is given by

l [compare Figs. 1(b-ii) and 1(b-iii),or1(b-iv)]. For longer l,

the condensate drops sweep a longer distance on the condens-

ing surface, resulting in on average larger sizes of the trapped

condensate droplets and also longer periodicity along the elec-

trodes [compare Figs. 1(b-iii) and 1(b-iv); Movies S3, S4, and

S5 show the condensate droplet pattern evolution correspond-

ing to l ¼ 1000 lm, 3000 lm, and 500 lm, respectively).

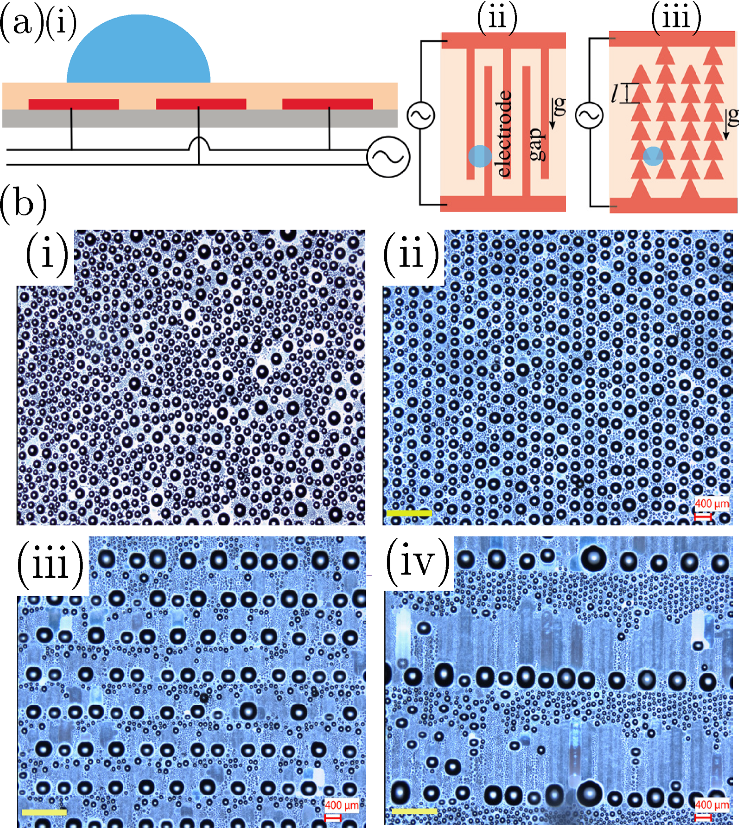

The final gravity-driven shedding characteristics are

quantified here by the average shedding radius hR

sh

i of the

FIG. 1. (a-i) Schematic of the substrate

used for the condensatio n experiments.

Schematics of the interdigitated elec-

trode (electrode-gap) designs are also

shown here—(a-ii) straight interdigi-

tated electrodes and (a-iii) zigzag inter-

digitated electrodes; the distance

l between the consecutive triangular ele-

ments is varied to create different elec-

trode designs. (b) Comparison between

condensate droplet patterns (at approxi-

mately the same time instant) (i) without

EW and under EW (U

rms

¼ 150 V;

f ¼ 1 k Hz) with different electrode

designs, (ii) straight interdigitated elec-

trodes, and zigzag interdigitated electro-

des with (iii) l ¼ 1000 lm and (iv)

l ¼ 3000 lm. Gravity points from top to

bottom along the electrodes. The yellow

bars in (b) represent 1 mm.

243703-2 Dey et al. Appl. Phys. Lett. 113, 243703 (2018)

condensate drops, and the average shedding rate hf

sh

i. hR

sh

i

represents the average value of R

sh

evaluated using an average

of more than 10 shedding events corresponding to a particular

EW condition, where R

sh

is evaluated using an image analysis

procedure [Fig. 2(a); see Sec. S1 in the supplementary mate-

rial]. The typical value of the percentage error involved is

16%. hf

sh

i is evaluated by dividing the total number of

recorded shedding events with the total time required for

those starting from the opening of the vapour valve for the ini-

tiation of the condensation process. Figure 2(b) clearly shows

that hR

sh

i progressively reduces under ac-EW, with straight

interdigitated electrodes, with increasing U

rms

; hR

sh

i for U

rms

¼ 150 V is approximately 50% smaller than that observed

without EW. Note that the values of R

sh

are typically larger

than the electrode pitch, and hence, the shedding drops cover

a few electrodes. In the absence of EW, hR

sh

i canbeesti-

mated from the balance between the droplet weight and the

inherent contact angle hysteresis (CAH) force acting on the

droplet

14

—hR

sh

i

ffiffi

3

p

q

k

c

ðD cos hÞ

1=2

.Here,k

c

¼

ffiffiffiffi

c

qg

q

is the

capillary length and c and q are the surface tension and the

density of water, respectively. D cos h is the difference

between the cosines of the receding and advancing contact

angles of water drops on the condensing surface; D cos h gives

a quantitative measure of the involved CAH (see Sec. S2 in

the supplementary material). It is now established that the

effective CAH under ac-EW in air gradually decreases with

increasing ac voltage.

15–17

This reduction in CAH is due to

the depinning of the droplet contact line from the random sur-

face heterogeneities induced by the oscillatory electrical

force, which is related to the associated oscillation of the

liquid-vapour interface.

15,18

The reduction in CAH with U

rms

can be expressed as D cos hðU

rms

ÞD cos h

0

abU

2

rms

,

where D cos h

0

is the value of D cos h for U

rms

¼ 0V,b is the

ratio of the effective dielectric capacitance per unit area and

c,anda is a coefficient characterizing the efficiency of the ac-

EW induced CAH reduction mechanism (generally a 1).

15,16

In this way, ac-EW reduces hR

sh

i with U

rms

for the case of

straight interdigitated electrodes [Fig. 2(b)]; hence, the corre-

sponding voltage dependent shedding radius can be estimated

as hR

sh

i

ffiffi

3

p

q

k

c

½D cos h

0

abU

2

rms

1=2

(also see Sec. S2 in

the supplementary material). It must be noted here that CAH

does not go on decreasing with increasing U

rms

but stabilize s at

a finite, albeit smaller, value at moderate values of U

rms.

15,16

Accordingly, the reduction in hR

sh

i is insignificant for higher

values of U

rms

[Fig. 2(b);Sec.S2inthesupplementary mate-

rial]. The gradually decreasing value of hR

sh

i, coupled with the

enhanced coalescence induced droplet growth under EW,

results in the increasing value of hf

sh

i [Fig. 2(c)]. In the case of

zigzag interdigitated electrodes [Fig. 2(d)], the non-uniform

overlap area between a condensate droplet footprint [the blue

filled circle in Fig. 2(d)] and the active electrode elements

results in a net electrical force on the droplet in the direction of

the converging gap. This net force is obtained by integrating

the vertical ð

^

vÞ component of the normal electrical force per

unit length ð

~

F

el

¼ F

el

^

n bcU

2

rms

^

nÞ along the droplet contact

line length on top of the electrode elements [Fig. 2(d);alsosee

Sec. S3 in the supplementary material]. This electrical force

sweeps the condensate drops towards the gap apices, thereby

enhancing coalescence and droplet growth. However, at the

gap apex, the orientation of the net vertical electrical force

FIG. 2. (ai) Representative image of a

condensate drop (outlined in red) about

to shed under gravity. The radius of

the drop at this instant is defined as the

shedding radius R

sh

. (aii) The conse-

quent frame showing the clearing of

the surface due to the droplet shedding.

(b) Variations of the average droplet

shedding radius hR

sh

i with the applied

voltage U

rms

for different electrode

designs, i.e., straight [Fig. 1(a-ii)] and

zigzag interdigitated electrodes with

different values of l [Fig. 1(a-iii)]; the

black solid curve with the black trian-

gles represents the theoretical esti-

mates corresponding to l ¼ 3000 lm

obtained using Eq. (1). (c) Variations

of the average shedding rate hf

sh

i with

U

rms

for the different electrode

designs. (d) Schematic of a condensate

droplet during dropwise condensation

under ac-EW with zigzag interdigi-

tated electrodes of varying l. The sche-

matic is not to scale.

243703-3 Dey et al. Appl. Phys. Lett. 113, 243703 (2018)

reverses the direction (from downward to upward) due to the

electrode geometry, which consequently traps the droplet at

that location [the dashed circle in Fig. 2(d) represents the foot-

print of the trapped droplet], in a manner similar to droplet

trapping by electrically tunable defects.

19

The condensate drops

thus accumulate at the gap apices till the droplet weight over-

comes the CAH force and the additional electrical trapping

force. So, for this case, hR

sh

i can be estimated from the relation

hR

sh

i

3

3

p

k

2

c

ðD cos h

0

abU

2

rms

ÞhR

sh

iþ

1:5

p

k

2

c

bU

2

rms

Dl

h

c

;

(1)

where the last term in Eq. (1) is due to the additional electri-

cal trapping force, Dl

h

c

represents the difference between the

horizontal projections of the total droplet contact line length

on the zigzag electrode elements above the horizontal droplet

footprint diameter and of the same below it, and a here takes

care of the possible non-uniformity in the ac-EW-induced

CAH reduction mechanism due to the zigzag electrode

geometry (also see Sec. S3 in the supplementary material).

Note that Dl

h

c

< 2hR

sh

i. Considering 2hR

sh

i as a scale for

Dl

h

c

, it can be inferred from Eq. (1) that for small values of

U

rms

, the reduction in CAH force and the additional electri-

cal trapping force [last two terms on RHS in Eq. (1)] almost

balance each other. Consequently, hR

sh

i for zigzag interdigi-

tated electrodes remains relatively unchanged for small val-

ues of U

rms

[Fig. 2(b)]. However, for large values of U

rms

,

the CAH force remains constant at a small finite value, while

the magnitude of the electrical trapping force progressively

increases ð/ U

2

rms

Þ. Hence, hR

sh

i increases with higher val-

ues of U

rms

for zigzag interdigitated electrodes [Fig. 2(b)].

Furthermore, Dl

h

c

in Eq. (1) increases with increasing l due to

the longer length of the droplet contact line on top of the elec-

trode elements with longer l [dashed electrode in Fig. 2(d)].

Accordingly, the electrical trapping force increases with

increasing l; consequently, hR

sh

i increases with increasing

l for a higher value of U

rms

[Fig. 2(b)]. Equation (1) provides

a reasonable estimate for hR

sh

i under ac-EW with zigzag

interdigitated electrodes, e.g., see the black solid curve with

the black triangles in Fig. 2(b) for rough theoretical estimates

of hR

sh

i for l ¼ 3000 lm (considering D cos h

0

0:13; b

8:5 10

6

F=ðNmÞ; a 0:8; Dl

h

c

Oð2hR

sh

iÞ). Finally,

the increasing value of hR

sh

i due to the electrical trapping

effect results in the lower shedding rate for the zigzag inter-

digitated electrodes, as compared to the straight interdigitated

electrodes [Fig. 2(c)].

Ac-EW with zigzag interdigitated electrodes indeed leads

to faster growth of condensate drops at earlier stages due

to the electrically induced droplet sweeping, as shown by

the temporal variations of the area-weighted average radius

of the condensate drops ðhriðtÞ¼Rr

3

=Rr

2

Þ [Fig. 3(a)]. hri

increases with increasing l [Fig. 3(a)] because the drops

sweep larger areas of the surface and thereby undergo more

coalescence before getting trapped, as can be seen in Fig.

1(b). However, this faster growth does not translate into a

higher shedding rate because of the electrostatic trapping

effect, as described before. The effect of electrostatic trapping

can be attenuated by applying U

rms

intermittently instead of

continuously, as shown in the inset in Fig. 3(b). During the

voltage-on phases, the sweeping and enhanced coalescence of

drops promote faster growth towards a radius k

c

[note that

in the absence of EW, hR

sh

iOðk

c

Þ]. Subsequently, the

voltage-off phases facilitate the gravity-driven shedding of

the sufficiently big condensate drops by turning off the

FIG. 3. (a) Temporal variations of the

area-weighted mean radius hri of the

condensate drops under ac-EW (U

rms

¼ 150 V) with different electrode

designs. (b) Variations of the average

shedding radius hR

sh

i with U

rms

under

continuous ac-EW (circles: straight

interdigitated electrodes; diamonds:

zigzag interdigitated electrodes with

l ¼ 3000 lm) and under intermittent

ac-EW (triangles: identical zigzag

interdigitated electrodes). The inter-

mittent ac-EW is achieved by switch-

ing the applied sinusoidal voltage on

(50 s) and off (10 s) as shown in the

inset. (c) Variations of the average

shedding rate hf

sh

i with U

rms

for con-

tinuous and intermittent ac-EW. (d)

Variations of the average volumetric

condensate removal rate h

_

v i with U

rms

for the different ac-EW conditions.

The symbols in (b)–(d) represent iden-

tical EW conditions.

243703-4 Dey et al. Appl. Phys. Lett. 113, 243703 (2018)

![FIG. 2. (ai) Representative image of a condensate drop (outlined in red) about to shed under gravity. The radius of the drop at this instant is defined as the shedding radius Rsh. (aii) The consequent frame showing the clearing of the surface due to the droplet shedding. (b) Variations of the average droplet shedding radius hRshi with the applied voltage Urms for different electrode designs, i.e., straight [Fig. 1(a-ii)] and zigzag interdigitated electrodes with different values of l [Fig. 1(a-iii)]; the black solid curve with the black triangles represents the theoretical estimates corresponding to l¼ 3000 lm obtained using Eq. (1). (c) Variations of the average shedding rate hfshi with Urms for the different electrode designs. (d) Schematic of a condensate droplet during dropwise condensation under ac-EW with zigzag interdigitated electrodes of varying l. The schematic is not to scale.](/figures/fig-2-ai-representative-image-of-a-condensate-drop-outlined-9aw9gxuz.png)