UCLA

UCLA Previously Published Works

Title

EWOD (electrowetting on dielectric) digital microfluidics powered by finger actuation.

Permalink

https://escholarship.org/uc/item/2nr7z58v

Journal

Lab on a chip, 14(6)

ISSN

1473-0197

Authors

Peng, Cheng

Zhang, Zhongning

Kim, Chang-Jin CJ

et al.

Publication Date

2014-03-01

DOI

10.1039/c3lc51223a

Peer reviewed

eScholarship.org Powered by the California Digital Library

University of California

Lab on a Chip

PAPER

Cite this: Lab Chip,2014,14,1117

Received 30th October 2013,

Accepted 17th December 2013

DOI: 10.1039/c3lc51223a

www.rsc.org/loc

EWOD (electrowetting on dielectric) digital

microfluidics powered by finger actuation

Cheng Peng,

a

Zhongning Zhang,

a

Chang-Jin “CJ” Kim

a

and Y. Sungtaek Ju

*

ab

We report finger-actuated digital microfluidics (F-DMF) based on the manipulation of discrete droplets via

the electrowetting on dielectric (EWOD) phenomenon. Instead of requiring an external power supply, our

F-DMF uses piezoelectric elements to convert mechanical energy produced by human fingers to electric

voltage pulses for droplet actuation. Voltage outputs of over 40 V are provided by single piezoelectric

elements, which is necessary for oil-free EWOD devices with thin (typically <1 μm) dielectric layers. Higher

actuation voltages can be provided using multiple piezoelectric elements connected in series when needed.

Using this energy conversion scheme, we confirmed basic modes of EWOD droplet operation, such as

droplet transport, splitting and merging. Using two piezoelectric elements in series, we also successfully

demonstrated applications of F-DMF for glucose detection and immunoassay. Not requiring power sources,

F-DMF offers intriguing paths for various portable and other microfluidic applications.

Introduction

Microfluidic devices are attractive for portable applications,

including point-of-care (POC) diagnosis, bio-surveillance, envi-

ronment sampling, and forensic science. They offer advantages

of low sample volume requirements and high reaction rates for

rapid analyses. However, most microfluidic systems require

bulky pumping and control systems as well as electrical outlets

to power them, limiting their field applications.

1

Previous studies proposed different approaches to

circumventing these challenges. Battery-powered microfluidic

devices with integrated microvalves and micropumps, for

example, have been reported for carrying out biological assays.

2

The resulting systems, however, were still too bulky for porta-

ble operations. “Passive” pumping mechanisms were also

explored. Paper-based microfluidic devices based on capillary

wicking attracted a lot of attention due to its perceived low

cost, lightweight and disposability.

3,4

Other passive pumping

mechanisms investigated include osmotic pressure,

5

built-in

vacuum

6

and human powered hydraulic pumping.

7,8

The fixed

layouts of continuous microfluidics employed in these devices,

however, limit their scalability and flexibility, making it diffi-

cult to adapt them on the fly to different protocols.

In digital microfluidics (DMF), droplets containing samples

or reagents are manipulated to carry out a range of discrete

fluidic operations. Precise control of individual droplets can be

achieved, thus providing greater flexibility and facilitating the

implementation of multi-step reactions.

9,10

The electrowetting on dielectric (EWOD) phenomenon

11

is

one of the most common actuation mechanisms used in

DMF and has been widely adopted in biomedical

12–16

and,

sometimes, other applications.

17,18

Traditional EWOD

devices, however, still require an external high-voltage supply

and switching circuitry, which require significant custom

development to realize compact systems.

19

We report EWOD-based DMF with finger-actuated voltage

generation on chip, or F-DMF, to eliminate the need for

external voltage sources. Fig. 1 schematically illustrates one

possible implementation of our device concept, which uses

an array of piezoelectric elements to convert mechanical

energy pulses provided by human fingers to voltage pulses.

Using this scheme, we confirmed basic modes of droplet

Lab Chip,2014,14,1117–1122 | 1117This journal is © The Royal Society of Chemistry 2014

a

Department of Mechanical and Aerospace Engineering, University of California,

Los Angeles, CA, USA. E-mail: just@seas.ucla.edu

b

Department of Bioengineering, University of California, Los Angeles, CA, USA

Fig. 1 Schematic of one implementation for the finger-actuated digital

microfluidic platform. The piezoelectric elements convert mechanical

energy imparted by human fingers to electrical energy to actuate droplets

confined between two parallel plates through the electrowetting on

dielectric (EWOD) phenomenon.

Published on 18 December 2013. Downloaded on 20/02/2014 17:10:00.

View Article Online

View Journal

| View Issue

1118 | Lab Chip,2014,14,1117–1122 This journal is © The Royal Society of Chemistry 2014

manipulation, such as transport, splitting and merging

of water droplets.

20

Furthermore, to demonstrate its capabil-

ity for biomedical applications, we successfully performed

the key assay steps involved in glucose detection and an

immunoassay.

EWOD device

Device design and fabrication

To successfully manipulate micro-droplets using EWOD, one

must generate voltage pulses of sufficient amplitude to over-

come capillary, inertial, and viscous forces. The EWOD-

induced contact angle change is related to the applied voltage

by the Lippmann–Young equation:

cos ( ) cos

V

t

V

0

0

LG

2

2

(1)

where θ

0

denotes the equilibrium contact angle at V =0V,ε

0

is the permittivity of vacuum, ε is the dielectric constant of

the dielectric layer separating the droplet from the electrode,

t is its thickness, and γ

LG

is the surface tension between the

droplet and surrounding. Since the contact angle change rep-

resents the actuation force along the surface, the higher the

applied voltage the stronger the actuation force that will drive

the droplet against the above-mentioned resistant forces.

Because the capillary resistance originated from the contact

angle hysteresis of an aqueous droplet surrounded in air

(as opposed to the popular oil environment) is larger than

the inertial or viscous resistance in most cases, performance

of EWOD devices is often measured in the air environment

without resorting to the filler oil or oil impregnation.

11

To

manipulate water droplets in air, typical EWOD devices

require a voltage source of about 40 V.

20

Our EWOD devices consist of two parallel glass plates that

were separated by approximately 100 μm. The bottom glass

plate contains an array of 1 × 1mm

2

gold electrodes, which

was fabricated using standard micro-fabrication processes.

We first deposited a 20 nm Cr/100 nm Au layer on a glass

wafer and patterned the layer by wet etching. Then, we depos-

ited a dielectric layer of silicon nitride by PECVD (plasma

enhanced chemical vapor deposition). We next spin coated a

solution of Teflon® AF (2% wt/wt in Fluorinert FC-40) at

2000 rpm for 30 seconds and baked it at 180 °C for

10 minutes to obtain a ~100 nm-thick hydrophobic topcoat. A

shadow mask was used to define electrical contact pads. The

top glass plate was coated with a transparent conductive ITO

(indium tin oxide, <15 ohm per square) layer to form a

counter electrode for EWOD. The counter electrode was also

coated with a ~100-nm-thick layer of Teflon®.

Due to the finite energy conversion efficiency of our piezo-

electric elements and safety consideration in portable appli-

cations, a low threshold actuation voltage and therefore a

thin dielectric layer is desired. However, a thin dielectric layer

is less robust and prone to pinholes and other defects, which

lead to electrolysis-induced failure of EWOD devices. The

dielectric layer thickness is further limited by the capacitance

allowed per EWOD electrode, which must be kept below that

of the piezoelectric element to minimize the voltage dividing

effect. With the above considerations in mind, we examined

SiNx layers of thickness ranging from 0.8 μm to 2.5 μmas

our dielectric layers. The estimated capacitance is approxi-

mately 60 pF per electrode for the EWOD devices with a

0.8 μm-thick dielectric layer, which is much smaller than that

of the piezoelectric element (~1 nF).

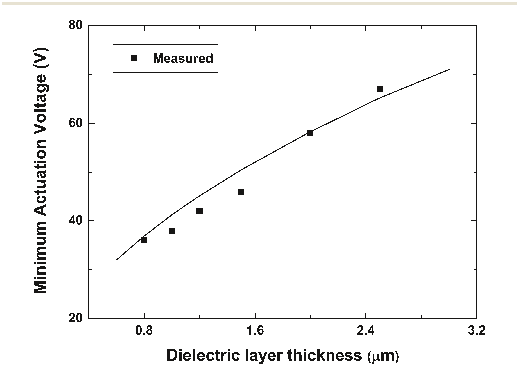

EWOD actuation voltage

To characterize the threshold actuation voltage required for

EWOD actuation as a function of the dielectric layer thick-

ness, an external programmable power source was used

to apply precisely defined voltage pulses. A water droplet of

~0.3 μL in volume was spotted onto the EWOD device and

subsequently split into two nominally identical daughter

droplets. After one of these droplets was positioned on one of

the electrodes, the amplitude of the voltage pulse applied to

the adjacent electrode was gradually increased until the drop-

let was successfully transported.

The threshold actuation voltage was recorded for each

dielectric layer thickness and the results are plotted in Fig. 2

(symbols). Also shown as a solid line in Fig. 2 are the voltages

required theoretically (eqn (1)) for the contact angle to

change from 120° to 70°, which is an empirically determined

range for droplet actuation in the given EWOD device. In

general, the threshold actuation voltage increases with the

increasing dielectric layer thickness. For EWOD devices with

a PECVD SiNx dielectric layer of thickness approximately

2.5 μm, a voltage as large as 70 V is required for successful

actuation of a water droplet.

Mechanical energy conversion

Piezoelectric elements of 13 × 25 mm

2

were used to convert a

mechanical energy input by human fingers into voltage

pulses to actuate micro-droplets in our EWOD DMF devices.

Fig. 2 Threshold actuation voltage of a water droplet on EWOD

devices as a function of the thickness of PECVD SiNx dielectric layers.

Lab on a ChipPaper

Published on 18 December 2013. Downloaded on 20/02/2014 17:10:00.

View Article Online

Lab Chip,2014,14,1117–1122 | 1119This journal is © The Royal Society of Chemistry 2014

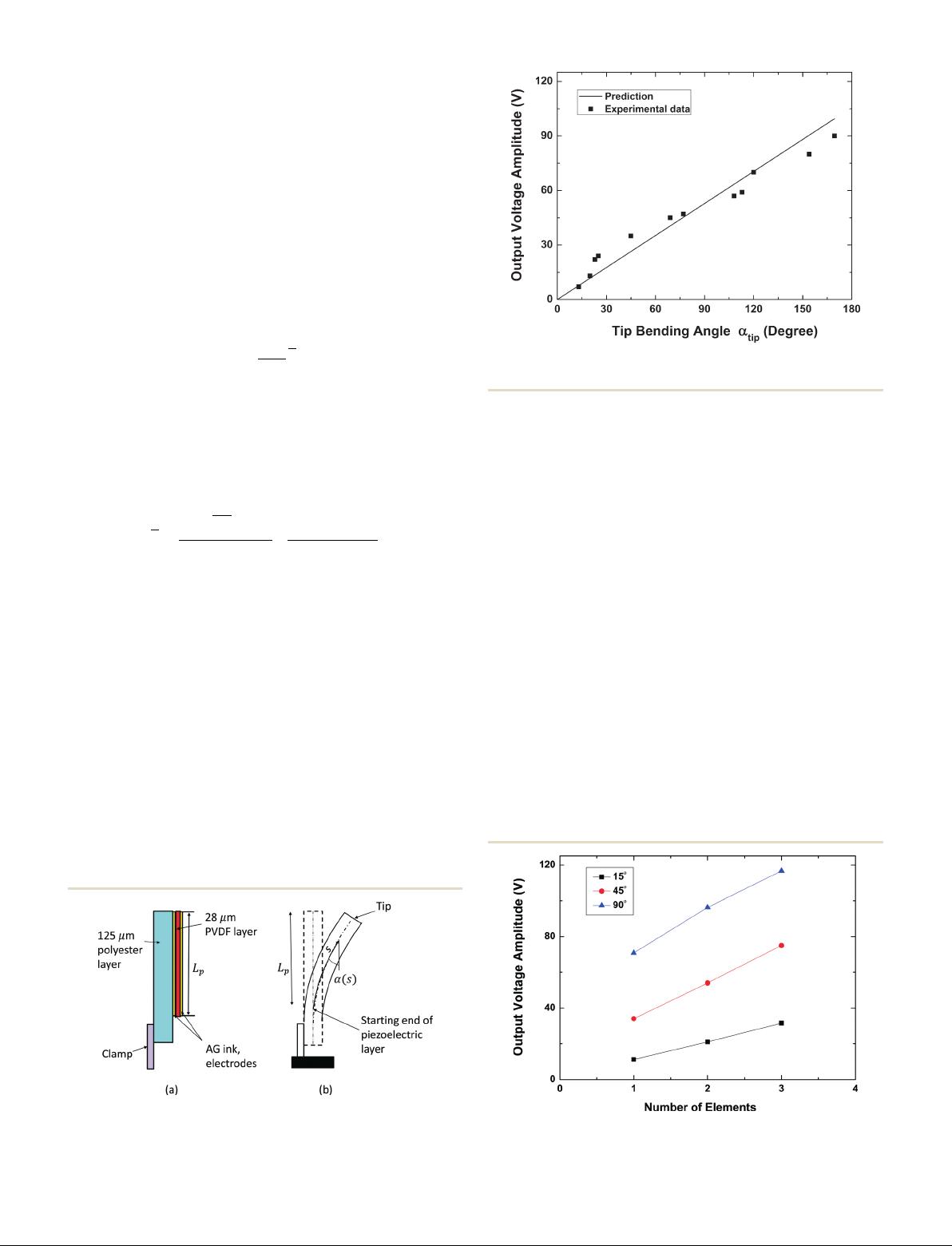

Each piezoelectric element consists of a PVDF (polyvinylidene

fluoride) layer of thickness 28 μm (piezoelectric layer) lami-

nated on a polyester layer of thickness 125 μm (substrate layer)

as illustrated in Fig. 3(a) to maximize the average strain in the

piezoelectric layer and hence its output voltage. The length of

the piezoelectric layer, L

p

, is approximately 20.5 mm.

We modelled each piezoelectric element as an Euler–

Bernoulli beam. The element (beam) is mounted vertically

with the clamped end fixed. The bending angle, α(s), is

defined as the rotation of the piezoelectric element beam

measured in radians at distance s from the fixed end, as illus-

trated in Fig. 3(b). For a single piezoelectric element, the

open circuit voltage can be expressed as:

21,22

V

eh

S

s

0

31

1

p

(2)

Here, e

31

is the electromechanical coupling coefficient of the

piezoelectric layer, ε

s

is the permittivity of the piezoelectric

layer under a constant strain and h

p

is the thickness of the

piezoelectric layer.

The average strain, S

¯

1

, is defined as:

S

s

yys

Lh

yy

Lh

Lh

h

h

h

1

0

1

2

1

2

p

dd

d

pp

tip

pp

()

()

(3)

where h

1

and h

2

are the distances from the neutral axis of

the whole beam to the bottom and top of the piezoelectric

layer, respectively; α

tip

and α

0

are the bending angles, α(s), at

the tip and at the starting end of the piezoelectric layer,

respectively (Fig. 3(b)).

To characterize the energy conversion capability of our

piezoelectric elements, the open-circuit voltage outputs were

measured using an electrometer of input impedance >200 TΩ.

Optical images of the side views of the element were captured

to extract the bending angles along the beam.

Fig. 4 shows the measured and predicted output voltages

as a function of the tip bending angle, α

tip

, for a single piezo-

electric element. The prediction (straight line) agrees reason-

ably well with the experimental results (symbols) over the

entire range. Output voltages greater than 40 V, which are

sufficient to reliably actuate a water droplet in the EWOD

device with a ~0.8 μm-thick SiNx dielectric layer, can be gener-

ated at tip bending angles greater than 80°. However, larger

deformations may not be desirable for field operations and

may also lead to degradation of the piezoelectric elements. We

estimated that the force required to achieve a bending angle of

36, 70 and 108° is approximately 0.06, 0.12 and 0.18 N,

respectively.

If needed, multiple piezoelectric elements may be

connected electrically in series and mechanically in parallel to

increase the output voltage while limiting required deflection

to an acceptable range. Fig. 5 shows the total output voltage of

single and two or three piezoelectric elements connected in

series. The results are shown for three different bending

angles. At relatively small tip bending angles (~15°), the total

voltage output increases linearly with each additional piezo-

electric element. At larger tip bending angles (45° and 90°),

adding more elements does not lead to a proportionate

increase in the output voltage. This is in part due to asynchro-

nous bending of each element and in part to finite leakage cur-

rents. Nevertheless, we demonstrated that output voltages on

Fig. 3 (a) Cross section of the main functional layers of a laminated

piezoelectric element used in the present study; (b) definitions of the

length, L

p

, and the bending angle, α.

Fig. 4 Open-circuit output voltages of a single piezoelectric element

as a function of the tip bending angle.

Fig. 5 Total voltage outputs from multiple piezoelectric elements

connected in series under different tip bending angles.

Lab on a Chip Paper

Published on 18 December 2013. Downloaded on 20/02/2014 17:10:00.

View Article Online

1120 | Lab Chip,2014,14, 1117–1122 This journal is © The Royal Society of Chemistry 2014

the order of 100 V can be reliably generated using piezoelectric

elements connected in series with tip bending angles <90°.

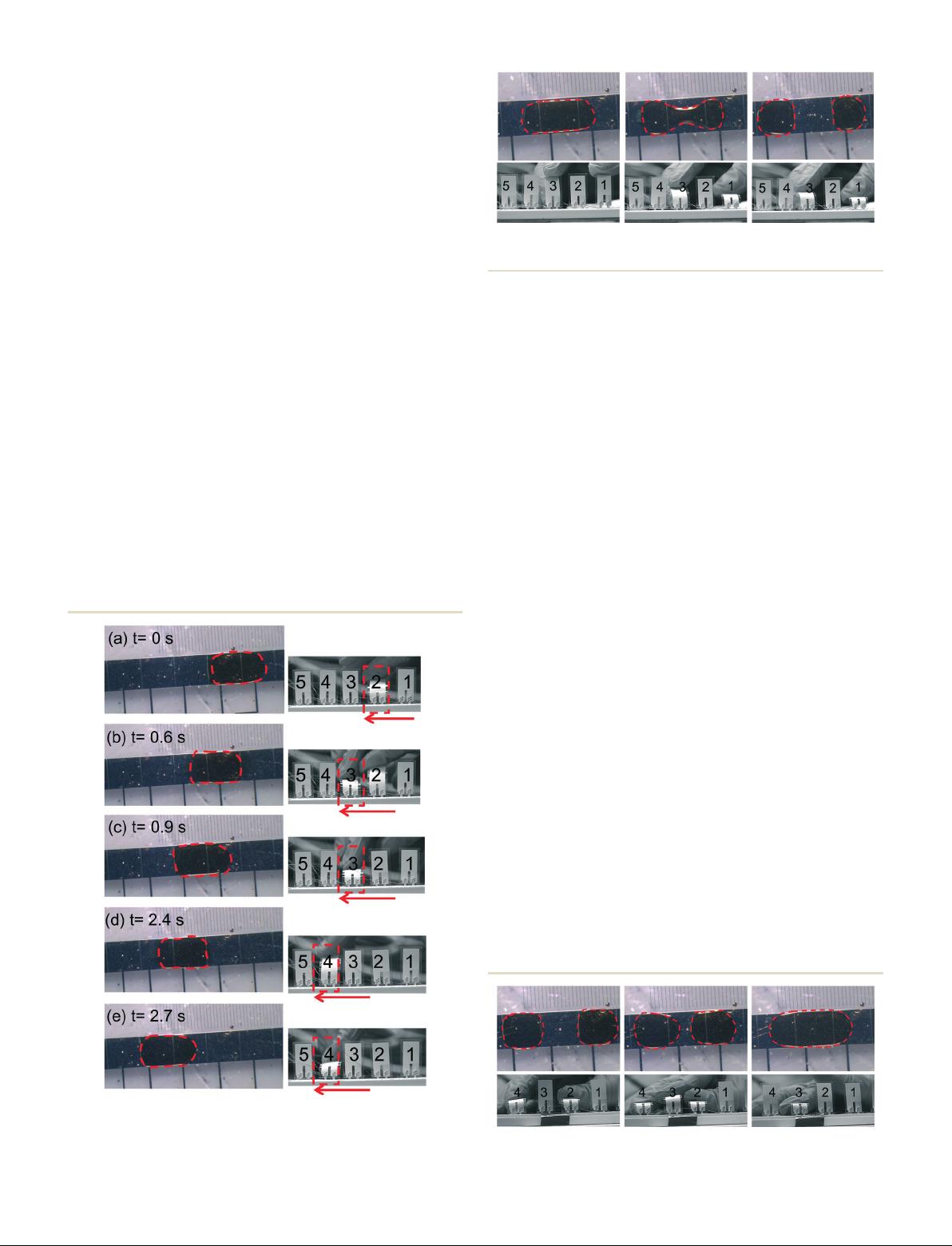

EWOD actuation of micro droplets

Basic droplet operations

We next demonstrated successful finger-powered actuation of

water droplets on EWOD devices with 0.8 μm-thick PECVD

SiNx dielectric layers. An array of single piezoelectric ele-

ments is used to convert mechanical energy to voltage pulses.

Fig. 6 shows optical images of a single water droplet (~0.15 μL)

being transported over adjacent electrodes through a sequence

of finger-driven deflection of the piezoelectric elements. To

avoid a droplet being trapped on an inactive zone between two

adjacent electrodes, we delayed the release of the previously

bent piezoelectric element while deflecting the neighbouring

element. For example, referring to Fig. 6, element 2 was not

entirely released when element 3 was deflected, such that the

front contact line of the droplet would stay across the gap

between electrodes 2 and 3. For such a delayed release, a

holding force of approximately 0.06 N is sufficient.

We also demonstrated droplet splitting by simultaneously

deflecting two non-adjacent piezoelectric elements while

keeping the middle one non-deflected. Fig. 7 illustrates a

splitting of a water droplet (~0.3 μL) into two daughter

droplets of similar sizes through simultaneous deflection of

element 1 and 3. When splitting was in order, the droplet was

elongated in the longitudinal direction by a wetting force

exerted at the two ends while keeping the middle non-wetting,

as shown in Fig. 6. The actuation voltage on either side is

approximately 40–50 V, produced by one single piezoelectric

element with a bending angle <90°. For a large droplet that

covers multiple electrodes, asymmetric splitting can also be

achieved by simultaneously deflecting a set of piezoelectric

elements connected to the electrodes in an asymmetric man-

ner, for example, elements 1 and 3, 4. Fig. 8 shows a merging

of two droplets of similar sizes by asynchronous bending and

release of three piezoelectric elements (2, 4, and 3).

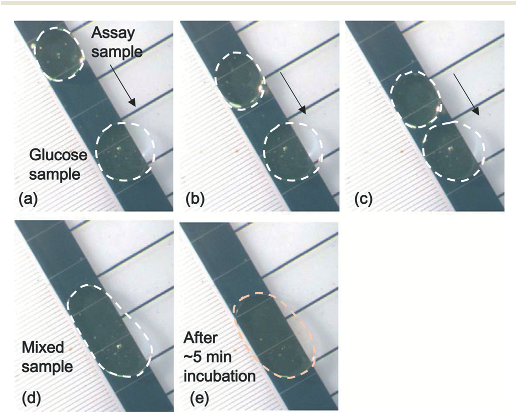

Applications to biological assays

As proof of principle demonstration of biological applications

of our F-DMF, we performed basic steps of glucose detection

and immunoassay. In these experiments, where higher

EWOD voltages are necessary to actuate droplets, we used

silicon nitride layers of thickness 2.5 μm because they help

prevent electrolysis of water under our low-frequency (~1 Hz)

finger-driven actuation scheme. Two piezoelectric elements

connected in series were used to provide an actuation voltage

of up to 100 V.

We demonstrated glucose detection based on an enzy-

matic oxidation, where the color of an assay solution changes

from clear to brown in the presence of glucose. Since the

reagent solution may chemically attack the hydrophobic coat-

ings, we pre-treated both the upper plate and bottom sub-

strate of our EWOD devices with silicone oil. A reagent

solution was prepared by adding 0.8 mL of o-dianisidine

reagent to an amber bottle containing 39.2 mL of a 1 : 5

horseradish peroxidase/glucose oxidase solution (15 units of

protein per mL of solution). We spotted a droplet of a 1 mg mL

−1

Fig. 6 Finger-actuated EWOD transport of a water droplet where

actuation voltage pulses were provided by bending a series of

piezoelectric elements.

Fig. 7 Finger-actuated EWOD droplet splitting. The piezoelectric

elements 1 and 3 are bent simultaneously for splitting.

Fig. 8 Finger-actuated EWOD droplet merging.

Lab on a ChipPaper

Published on 18 December 2013. Downloaded on 20/02/2014 17:10:00.

View Article Online