Fatigue fracture of tough hydrogels

Figures (7)

Fig. 1 Shakedown after prolonged cycling. (a) A sample of tough hydrogel is cyclically stretched in the pure shear test. (b) The loading profile of the test. Shakedown of stress-stretch curves was observed in tests with different loading frequencies, and shows no significant rate dependence: The loading frequency is (c) 0.25 Hz, (d) 0.125 Hz.

Fig. 4 Crack growth as a function of the number of cycles N, under different maximum stretches. The crack growth reaches the steady state after thousands of cycles, and becomes approximately a linear function of N.

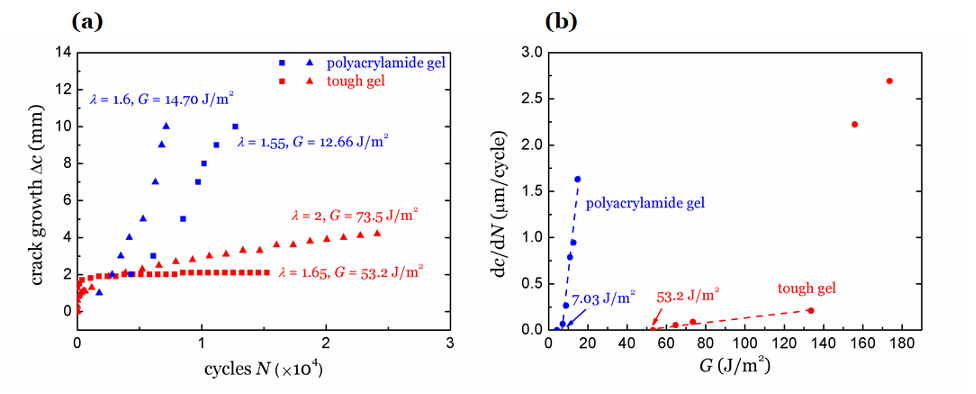

Fig. 7 Comparison between a polyacrylamide hydrogel and a tough hydrogel in fatigue fracture. (a) The crack growth of the polyacrylamide hydrogel is faster (steeper slope) than that of the tough hydrogel, even under a less critical condition (smaller and G per cycle). (b) The fatigue threshold of the tough hydrogel is higher than that of the polyacrylamide hydrogel. The slope of dc/dN vs. G in the tough hydrogel is much lower than that in the polyacrylamide hydrogel. Both factors show that tough hydrogels have better fatigue fracture resistance than polyacrylamide hydrogels.

Fig. 6 (a) A polyacrylamide hydrogel maintains stable stress-stretch loops over thousands of cycles. (b) The maximum stress in each cycle remains nearly constant over cycles.

Fig. 2 (a) The maximum stress in each cycle decreases and approaches a steady state. (b) The stress-stretch curves after 2000 cycles for different maximum stretches .

Fig. 5 (a) The energy release rate is calculated by integrating the stress-stretch curve in the steady state of the material far ahead of the crack tip. (b) In the steady state, the extension of crack per cycle, dc/dN, is plotted as a function of energy release rate G. A threshold is found, below which no crack propagation in the steady state occurs. Close above the threshold, dc/dN is found as a linear function of G. dc/dN then increases rapidly with G.

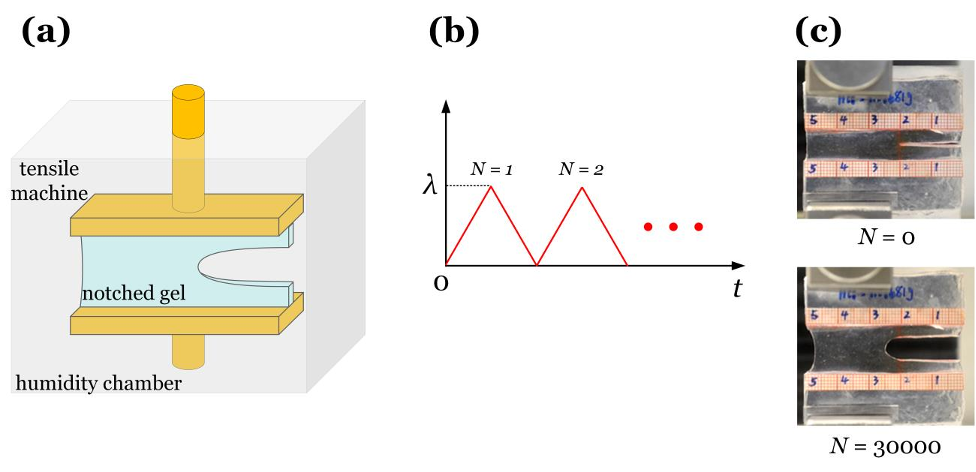

Fig. 3 Fatigue fracture. (a) A notched sample is cyclically stretched. The sample and the grips are enclosed in a chamber with water droplets on its inner surface to control the humidity of the environment. (b) The applied loading profile over cycles. (c) The crack propagates cycle by cycle, and the evolution is recorded by photos. The crack propagation can be measured from the metric papers on the grips.

Citations

444 citations

312 citations

299 citations

276 citations

258 citations

References

4,511 citations

[...]

4,158 citations

"Fatigue fracture of tough hydrogels..." refers background in this paper

...Shakedown has been extensively studied in ductile metals [26]....

[...]

3,856 citations

"Fatigue fracture of tough hydrogels..." refers background or methods in this paper

...Several strategies have been developed to synthesize tough hydrogels, including double network hydrogels [13, 14], nano- and micro-composite hydrogels [15-17], as well as tri-block copolymers and hydrophobic associated hydrogels [18, 19]....

[...]

...The fatigue threshold of the tough hydrogel is about 53 J/m2, whereas the fracture toughness of the tough hydrogel under monotonic load easily reaches several thousands of J/m2....

[...]

...We focus on a polyacrylamide-alginate tough hydrogel, where polyacrylamide forms a network of covalent crosslinks, and alginate forms a network of ionic crosslinks [14]....

[...]

...The threshold for fatigue fracture is about 53 J/m2, much below the fracture energy (~10,000 J/m2) measured under monotonic load....

[...]

...The re-zipping of the calcium crosslinks takes hours to days [14], and does not occur within the time period of each cycle....

[...]

3,307 citations

"Fatigue fracture of tough hydrogels..." refers background or methods in this paper

...Several strategies have been developed to synthesize tough hydrogels, including double network hydrogels [13,14], nano- andmicro-composite hydrogels [15–17], as well as tri-block copolymers and hydrophobic associated hydrogels [18,19]....

[...]

...High toughness of these hydrogels is achieved by breaking sacrificial bonds, such as covalent bonds in a short-chain network [13], or ionic crosslinks [14,18]....

[...]

2,195 citations