1

Functional behaviour of TiO

2

films doped with noble metals

M.S. Rodrigues

1,2 *

, J. Borges

1,3

, C. Gabor

4

, D. Munteanu

4

, M. Apreutesei

5

, P. Steyer

5

, C. Lopes

1,2

,

P. Pedrosa

1,3,6

, E. Alves

7

, N.P. Barradas

8

, L. Cunha

1

, D. Martínez-Martínez

1

, F. Vaz

1,3

1

Centro/Dep. de Física, Universidade do Minho, Gualtar, 4710 - 057 Braga, Portugal

2

Instituto Pedro Nunes, Lab. de Ensaios, Desgaste e Materiais, Rua Pedro Nunes, 3030-199

Coimbra, Portugal

3

SEG-CEMUC, Mechanical Engineering Dep., Univ. of Coimbra, 3030-788 Coimbra, Portugal

4

Materials Science Department, Materials Science and Engineering Faculty, Transilvania

University of Brasov - Romania, 500036, 29 Eroilor Blvd.

5

INSA de Lyon, MATEIS Laboratory, Eq. CorrIS/SNMS, Bât. B. Pascal, 7 Av Jean Capelle,

69621-Villeurbanne, France

6

Universidade do Porto, Faculdade de Engenharia, Departamento de Engenharia Metalúrgica e de

Materiais, Rua Dr. Roberto Frias, s/n, 4200-465 Porto, Portugal

7

Instituto de Plasmas e Fusão Nuclear, Instituto Superior Técnico, Universidade de Lisboa, Av.

Rovisco Pais, 1049-001 Lisbon, Portugal

8

Centro de Ciências e Tecn. Nucleares, Instituto Sup. Técnico, Univ. de Lisboa, E.N. 10 (km

139.7), 2695-066 Bobadela, Portugal

* Corresponding author – mprodrigues@ipn.pt ; marcopsr@gmail.com; +351 966 458 876

Abstract

To evaluate the effects of different concentrations of noble metal in a TiO

2

matrix, different films

of both Ag:TiO

2

and Au:TiO

2

systems were prepared. Mechanical and tribological

characterization was carried out to evaluate the coatings response as a function of the noble metals

composition and (micro)structure of the films. The overall set of results indicates that the

amorphous films reveal better results than the crystalline ones. For the amorphous samples, the

2

reduced Young’s modulus and the adhesion critical loads followed similar tendencies in both sets

of films. Wear rates were similar for all samples except for the one with the highest silver content.

To improve brittleness of TiO

2

films, the results seem to indicate that a slight metal doping is

preferred, and Au showed to be a better choice than Ag. In fact, the sample with the lowest Au

content revealed a better mechanical behaviour than the pure TiO

2

film.

Keywords: Magnetron sputtering; Thin films; Brittleness; Noble metal doping; Titanium dioxide

Nomenclatures / abbreviations:

Mole %

Poisson ratio

Ag

Silver

Ar

Argon

at.%

Atomic %

Au

Gold

DC

Direct Current

E*

Reduced Young's modulus

ECG

Electrocardiography

EEG

Electroencephalography

EMG

Electromyography

fcc

Face-centered cubic

H

Hardness

LSPR

Localised Surface Plasmon Resonance

n

Number of mole

NPs

nanoparticles

PVD

Physical Vapor Deposition

RBS

Rutherford Backscattering Spectrometry

SEM

Scanning Electron Microscopy

SERS

Surface-Enhanced Raman Spectroscopy

Si

Silicon

TiO

2

Titanium dioxide

XRD

X-Ray Diffraction

1. Introduction

Titanium dioxide (TiO

2

) is a transparent semiconductor material, with a high bandgap, varying

between 3.0 and 3.4 eV

1-4

. Concerning its behaviour, TiO

2

is known for its biocompatibility, non-

toxicity, chemical stability, high hardness and high optical transmittance, combined with a high

refractive index, between 2.4 and 2.9

5-10

. Due to these characteristics, TiO

2

is widely used in

3

several optical devices, biomedical applications, dye sensitised solar cells, photo-electrolysis,

photocatalysis, as a coating for anti-fogging and evn as a self-cleaning coating material for glasses

5, 6, 11

. In basic terms, TiO

2

exists in both amorphous and crystalline forms. Specifically, the two

most important crystalline forms are anatase and rutile, both showing a tetragonal-like structure

lattice

12

. Among these phases, anatase is known for its excellent photocatalytic activity

12

and it is

kinetically stable at low temperatures. In the rutile form, TiO

2

has good structural stability at high

temperatures, together with a higher refractive index

13

. On the other way around, in the

amorphous form,TiO

2

has high blood compatibility and thus it is often used in several types of

biomedical applications

14

.

Brittleness is an important feature for any kind of thin films system, which may restrict its use in

some applications that require flexible substrates

15-17

. The case of thin film systems designed for

polymeric base electrodes or sensors to be used in several types of biomedical applications,

including electroencephalography, EEG, and electrocardiography ECG

18

and electromyography,

EMG

15, 19, 20

, as well as some kinds of biological sensors

21

are particularly noticeable examples,

that are being develop in the group for some time. To overcome this drawback and improve

flexibility of the coated devices, the tailoring of the elastic modulus

22

of the thin film systems by

adding silver (Ag) or gold (Au) to such oxide material, is one of the most promising routines that

can be optimized. At the same time, the dispersion of such noble metals (Au, Ag) throughout the

TiO

2

matrix can create thin films with metallic nanoparticles (NPs), responsible for the so-called

localised surface plasmon resonance (LSPR)

23

, which gives rise to a set of unique properties that

enables the film system to be used in some appliactions that were fristly impossible when ussing

pure oxide-type films.

Furthermore, the absorption bands in the visible spectra range are the main feature associated with

the presence of Au and Ag nanoparticles

23

. This effect can produce a palette of colours

9

if one

can tune the LSPR position, the bandwidth and peak height through changes on the size,

distribution and shape of the NPs, as well as on the host dielectric matrix (such as TiO

2

).

Consequently, the tailoring of the optical properties of the nanocomposites is possible

24-26

.

4

Beyond colouring that was used for several centuries in the windows of the medieval cathedrals

and ancient Roman glass cups, advanced applications of such plasmonic nanocomposite materials

include: solar cells, optoelectronic devices, biosensors, gas sensors, magnetic storage, energy

conversion, optical filters, photocatalysis and surface-enhanced Raman spectroscopy (SERS)

27-35

.

As mentioned before, to overcome the limitation of experimental conditions, LSPR thin films

have to be developed with higher robustness and flexibility in order to support mechanical stress.

Taking this into account, and in order to evaluate the effects of different concentrations of Au and

Ag in a TiO

2

matrix, several thin films of Ag:TiO

2

and Au:TiO

2

systems were produced by

reactive magnetron sputtering. This physical vapour deposition technique was chosen since it is

known to be an environmentally friendly coating process that provides durable materials with low-

cost production, when compared to the traditional preparation methods

42

. The determination of

hardness, reduced Young’s modulus, wear rate and critical loads

36-38

was performed in order to

evaluate the brittleness of the coatings and to correlate the mechanical behaviour with the

composition and (micro)structure of the films

17, 39-44

.

2. Experimental details

The Au:TiO

2

and Ag:TiO

2

thin films were prepared by reactive DC magnetron sputtering

45

, on Si

(Boron doped p-type, <100> orientation, thickness of 525 µm), in a custom-made deposition

system

45

. The system is composed of a cylindrical deposition chamber (~40 dm

3

), a pre-chamber,

a vacuum system, a gas flow controller, an electrical system and a control unit. The deposition

chamber is composed by two vertically aligned rectangular magnetrons, in a closed field

configuration. To produce the films, only one magnetron was used, powered by a Hüttinger PFG

7500 DC (maximum output of 7.5 kW). The primary vacuum of the deposition chamber (with

pressures of ~0.3 Pa) is achieved using a rotary vane vacuum pump, a Balzers Duo 012A. The

secondary vacuum (with pressures of ~10

−4

Pa) is obtained using a TurboMolecular vacuum

pump, model PTM 5400 (400 L.s−1) from Alcatel. To measure the gas pressure, the system is

controlled by a Leybold Penningvac PTR225 (10

−7

–10 Pa) and a Leybold Sky-Pirani Gauge

5

TR090 (10

−2

–10

5

Pa). The films were prepared using a substrate holder positioned at 70 mm from

the target, in a rotation mode-type (9 rpm). A titanium target (200×100×6 mm

3

, 99.8% purity)

containing different amounts of Au, or Ag, pellets (1 mm thick and 4.5 mm in diameter) incrusted

in the erosion track of the Ti target was used. The number of Au or Ag pellets was changed to

vary the flux of Au or Ag atoms towards the substrate and thus obtain films with different noble

metal concentrations. The power supply connected to the target was set to operate in the current

regulating mode, using a current density of 100 A.m

-2

on the Ti-Au, or Ti-Ag, target. The films

were prepared using an atmosphere composed of Ar and O

2

leading to a total pressure of about

4×10

-1

Pa. To promote and enhance the adhesion of the films, the Si substrates were treated using

an in situ etching process in Ar (pressure of about 5×10

-1

Pa) under a pulsed DC current of 0.5 A

with a duty cycle of 30%, during 1200 s. Find the etching and deposition parameters summarized

in Table 1.

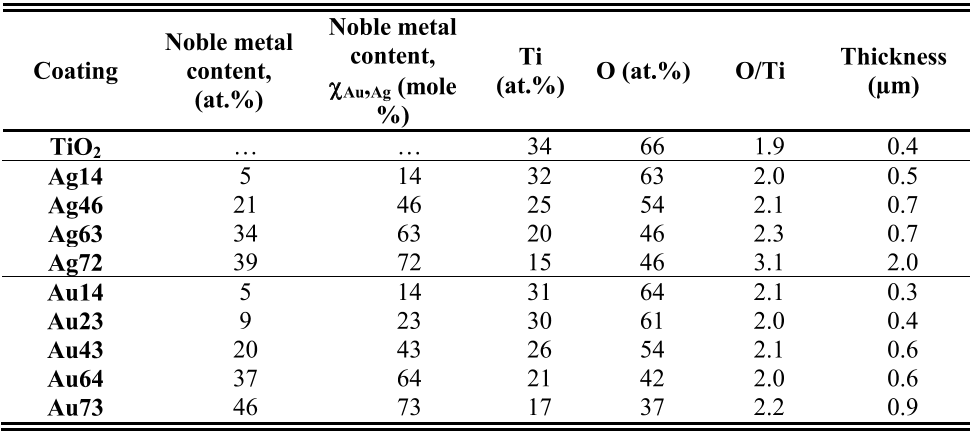

Table 1 – Etching and deposition parameters to produce the coatings

The

dep

osit

ion

par

ame

ters,

such as the target potential and current, gas pressure, argon flow and reactive gas flows, were

monitored before and during the deposition, using a Data Acquisition/Switch Unit Agilent

34970A, equiped with a multifunction module (334907A), where the cables (from analog outputs

Parameter

Etching

Deposition

Power Source

Pulsed DC Current (T

on

= 1536 ns,

f = 200kHz)

DC Current

Ar (sccm)

70

60

O

2

(sccm)

-

7.5

Time (s)

1200

3600

Current (A/m

2

)

25

100

T (ºC)

100

100

Bias

-

Grounded

P

Work

(Pa)

510

-1

410

-1

P

Base

(Pa)

~10

-5

10

-5