Did you find this useful? Give us your feedback

16 citations

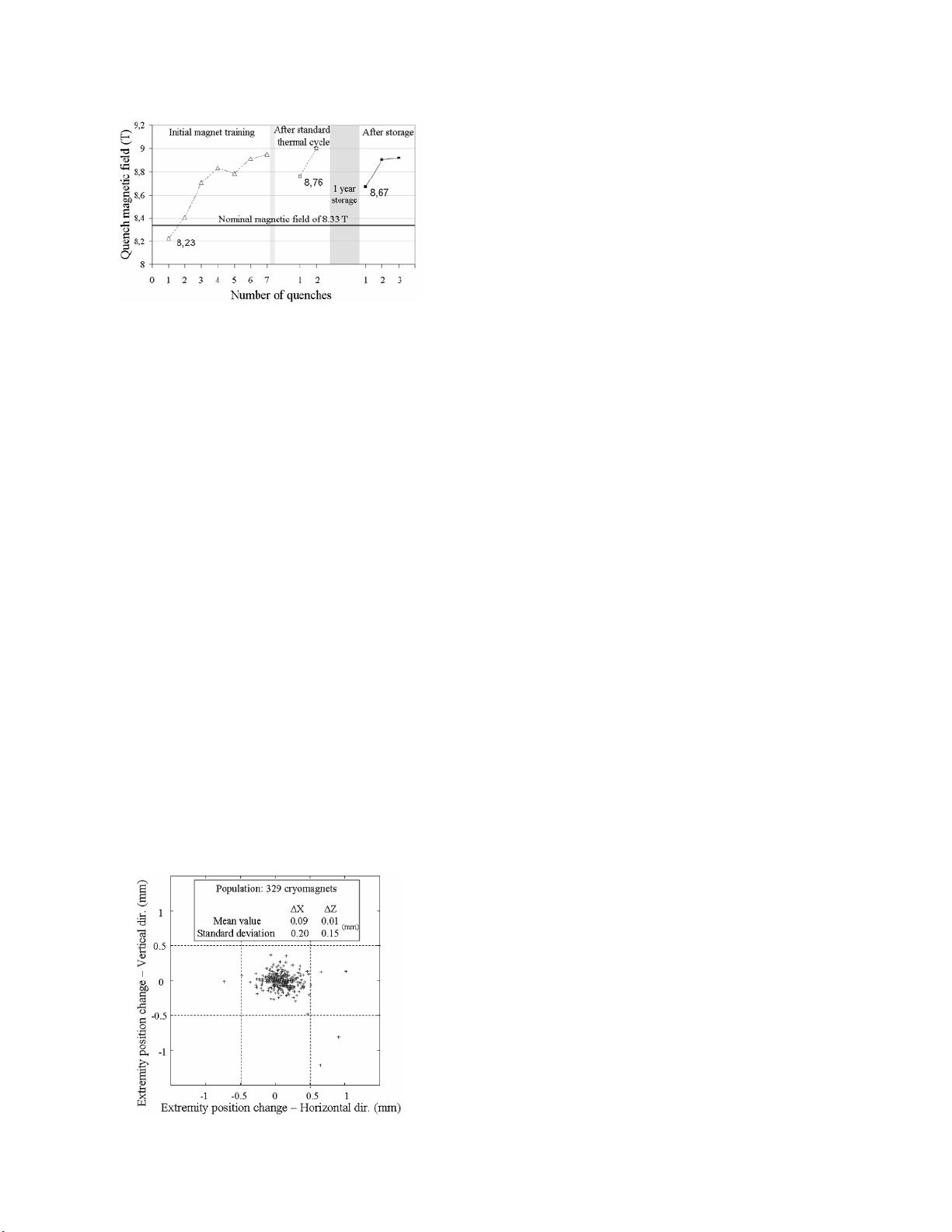

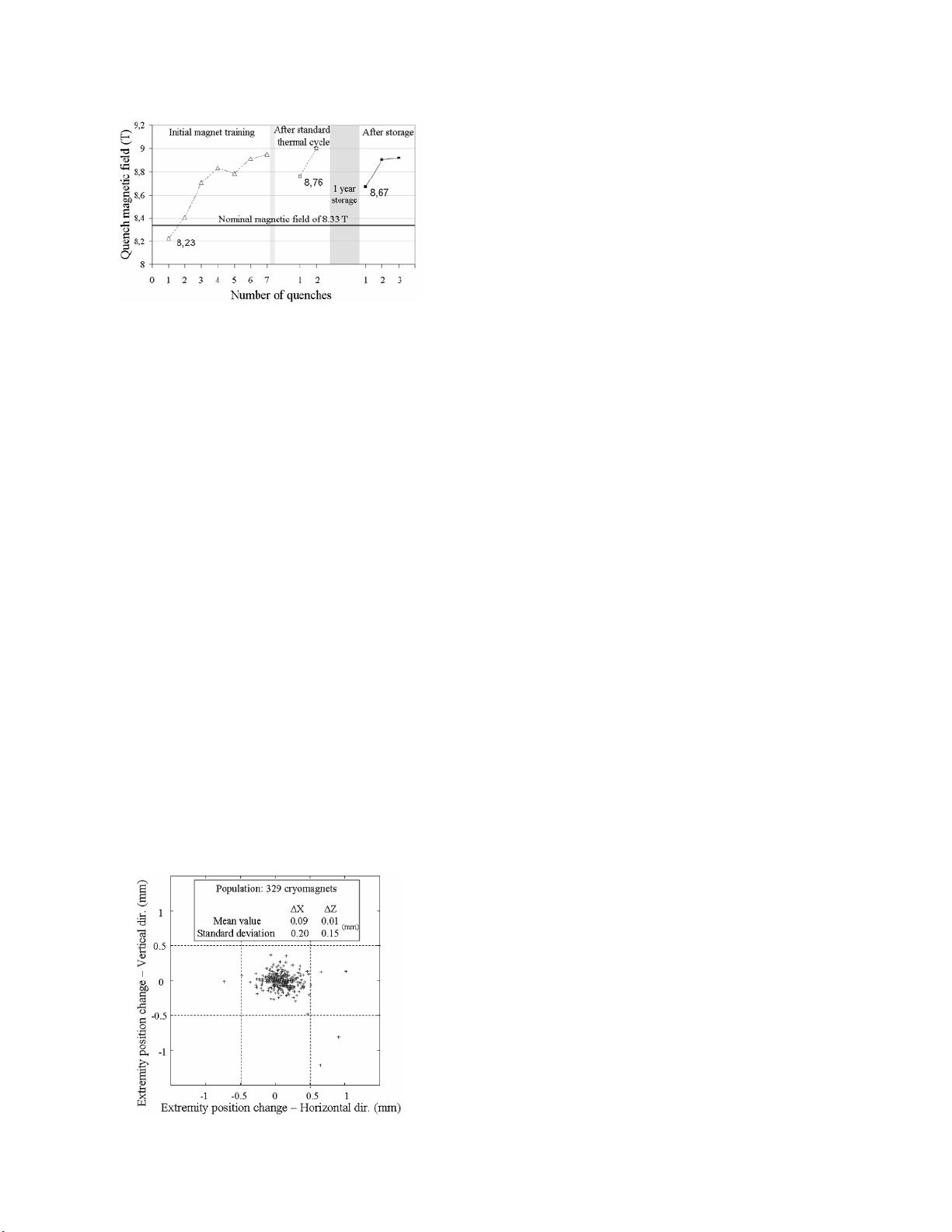

...geted MB for the study of the long term stability did not reveal a significant drift of the quench performance after about 1 year of storage [28]....

[...]

[...]

11 citations

...The observed behaviour is contradictory to the conclusion drawn in [1], namely that long term storage does not affect the quench behaviour of the cryodipoles....

[...]

1 citations

...These results also validate the performance of the LHC magnet cryostats after long term (up to 3 years) outdoor storage prior to installation [11] and shows that installation and interconnection activities have not degraded in any significant way the thermal performance of the cryostats....

[...]

1 citations

7 citations

...A mechanical model of the dipole cross-section, previously developed and validated with experimental data [3], was used to evaluate the influence of coil pre-stress on field quality....

[...]

2 citations

...The extended duration of outdoor storage was questioned to eventually enhance the creep in the coil structure [2]....

[...]

A dedicated task force was established to study all aspects of long term behaviour of the stored cryodipoles, with particular emphasis on electrical and vacuum integrity, quench training behaviour, magnetic field quality, performance of the thermal insulation, mechanical stability of magnet shape and of the interface between cold mass and cryostat, degradation of materials and welds. This paper summarizes the main investigations carried out and their results.

The leakage currents flowing in-between main insulated magnet components were measured at 1.9 K with maximum applied voltages of 2.7 kV and 3.1 kV as a function of theelectrical circuits.

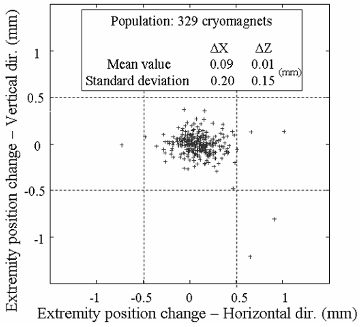

The main risks have been identified as, first, a degradation of the friction coefficient of the PTFE® coated surface allowing sliding of the extremity support posts on the cryostat; and, second, a decrease of the stiffness of the GFRE support posts eventually degrading the alignment stability of the LHC magnets in the machine.

The cleaning of the beam tubes and subsequent insertion of the beam screens are performed before lowering down the cryomagnet into the 27-km circumference tunnel.

The air moisture in the vacuum vessel during outdoor storage might oxidize the 40 nm aluminium coating deposited on each side of the MLI layers.

Measurements of the field quality at CERN show that the offsets between warm and cold field measurements in b3 are stable within ±0.5 units, regardless of the time of storage of the magnets.

2. The conditioning of the cold masses and cryodipoles includes protection of electrical cabling, installation of leak tight covers on both magnet and vacuum vessel extremities and pressurization of the cold mass with 1.2 bar of gaseous nitrogen.

VacuumCondensation and re-evaporation cycles in the vacuum enclosures are possible during outdoor storage; the oxidation of the vacuum system was therefore investigated.

The long-term behaviour of the LHC main superconducting dipoles stored outdoors has been investigated, with a focus on electrical integrity, magnetic field quality, quench training, geometry, degradation of materials and welds, performance of the thermal insulation and interface between the cold mass and the cryostat.

The position change of the cold mass extremities within the cryostat has been studied, as it is representative of both the corrector magnet alignment and the sagitta change of the dipole.

Magnets stored outside for a period of one year that had already been equipped with beam screens and cooling circuits were inspected, and 3 of them were leak tested.

Thanks to the inspection work done, a manufacturing non conformity in a cold mass critical weld was monitored and treated, and the quality control of the storage conditions was improved.

The analysis has shown that dipole cryomagnets remain functionally unaffected or weakly affected by long-term outdoor storage, even if such a constraint was not considered during the design phase.

The thermal performance of a production sample that was stored in an unprotected environment for a period of more than two and a half years has been analyzed and tested [5].

A specific hygrothermal ageing treatment of both GFRE supports posts and low-friction centering pieces has been defined, based on a series of humidity absorption and desorption cycles on samples of the GFRE composite material.

The geometry stability of the LHC cryodipoles has been assessed by comparing their geometry between two stages; before outdoor storage once they are assembled and cold tested; and after storage when the beam screens are inserted into the beam tubes.

A mechanical model of the dipole cross-section, previously developed and validated with experimental data [3], was used to evaluate the influence of coil pre-stress on field quality.