Morphology and microstructure evolution of Ti-50 at.% Al cathodes during cathodic arc

deposition of Ti-Al-N coatings

Bilal Syed, Jianqiang Zhu, Peter Polcik, Szilard Kolozsvari, Greger Håkansson, Lars Johnson, Mats Ahlgren,

Mats Jöesaar, and Magnus Odén

Citation: Journal of Applied Physics 121, 245309 (2017); doi: 10.1063/1.4990425

View online: http://dx.doi.org/10.1063/1.4990425

View Table of Contents: http://aip.scitation.org/toc/jap/121/24

Published by the American Institute of Physics

Morphology and microstructure evolution of Ti-50 at.% Al cathodes

during cathodic arc deposition of Ti-Al-N coatings

Bilal Syed,

1

Jianqiang Zhu,

1

Peter Polcik,

2

Szilard Kolozsvari,

2

Greger Ha˚kansson,

3

Lars Johnson,

4

Mats Ahlgren,

4

Mats J

€

oesaar,

1,5

and Magnus Od

en

1

1

Nanostructured Materials, Department of Physics, Chemistry, and Biology (IFM), Link

€

oping University,

SE-581 83 Link

€

oping, Sweden

2

PLANSEE Composite Materials GmbH, DE-86983 Lechbruck am See, Germany

3

Ionbond Sweden AB, Box 1161, SE-58111 Link

€

oping, Sweden

4

Sandvik Coromant, 126 80 Stockholm, Sweden

5

SECO Tools AB, SE-737 82 Fagersta, Sweden

(Received 3 May 2017; accepted 14 June 2017; published online 29 June 2017)

Today’s research on the cathodic arc deposition technique and coatings therefrom primarily

focuses on the effects of, e.g., nitrogen partial pressure, growth temperature, and substrate bias.

Detailed studies on the morphology and structure of the starting material—the cathode—during

film growth and its influence on coating properties at different process conditions are rare. This

work aims to study the evolution of the converted layer, its morphology, and microstructure, as a

function of the cathode material grain size during deposition of Ti-Al-N coatings. The coatings

were reactively grown in pure N

2

discharges from powder metallurgically manufactured Ti-50 at.%

Al cathodes with grain size distribution averages close to 1800, 100, 50, and 10 lm, respectively,

and characterized with respect to microstructure, composition, and mechanical properties. The

results indicate that for the cathode of 1800 lm grain size the disparity in the work function among

parent phases plays a dominant role in the pronounced erosion of Al, which yields the coatings rich

in macro-particles and of high Al content. We further observed that a reduction in the grain size

of Ti-50 at.% Al cathodes to 10 lm provides favorable conditions for self-sustaining reactions

between Ti and Al phases upon arcing to form c phase. The combination of self-sustaining reaction

and the arc process not only result in the formation of hole-like and sub-hole features on the con-

verted layer but also generate coatings of high Al content and laden with macro-particles.

Published by AIP Publishing. [http://dx.doi.org/10.1063/1.4990425]

I. INTRODUCTION

Cathodic arc deposition is the quotidian PVD technique

used to deposit hard coatings on cutting tools. This technique

owes its expedience to the fact that the metal plasma formed

during the process is highly ionized and dense.

1

It begets

good adhesion, high deposition rates, and dense coatings

with compressive stress,

2

which result in superior mechani-

cal properties.

3

The demands for higher cutting speeds during turning

and milling operations require the coatings on cutting tools

to withstand extreme and harsh conditions of high tempera-

tures and pressures, which has motivated extensive research

on multinary ceramic materials. For example, detailed under-

standing and abundant research material on Ti-Al-N,

4

Zr-

Al-N,

5

Ti-Si-N,

6

etc., are readily available. Current research

in this field has mainly been directed to tailor and understand

the optimum microstructure by compositional variance.

These multinary ceramic coatings are generally grown by

using powder metallurgically produced multiphase cathodes,

such as Ti-Al,

7

Zr-Al,

8

Ti-Si,

9

etc., arced in the presence of

the reactive gas N

2

.

The perpetual existence of cathode spot(s) on the cath-

ode surface is the very essence of the cathodic arc deposi-

tion process. In addition, the cathode spots dynamics can

be influenced by, e.g., the microstructure of the cathode,

which in turn may lead to changes in the microstructure of

the coatings and, hence, also of its properties.

9

Depending

on cathode material, the electron temperatures between 2

and 5 eV have been reported in the vicinity of cathode

spots.

10

The presence of such high electron temperatures,

in proximity to the cathode surface, modifies its micro-

structure to a depth of several micrometers to form a con-

verted layer.

11

Most investigations on how to control coating micro-

structure and composition by manipulating the cathodic arc

process are chiefly focused on the aspects of ambient gas

pressure,

12

bias voltage,

13

deposition temperature,

14

and

magnetic steering

15

of the cathode spot. However, the influ-

ence of the microstructure of the cathode on the synthesis of

coating, their microstructure, and composition is almost

never considered. Although the interplay of multiple phases

in the cathode, the reactive gas, and the localized ultrahigh

temperatures due to the transient nature of the cathode spots

causes intermixing of the parent phases and the formation of

new phases in the converted layer. In-depth knowledge of

such mechanisms is needed for a comprehensive understand-

ing of the arc deposition process and perhaps a mean to con-

trol the microstructure and composition of arc deposited

coatings. This work focuses on the evolution of the con-

verted layer on the cathode surface, its morphology, and

microstructure, as a function of the Ti-50 at.% Al cathode

0021-8979/2017/121(24)/245309/11/$30.00 Published by AIP Publishing.121, 245309-1

JOURNAL OF APPLIED PHYSICS 121, 245309 (2017)

material, with the average grain size distribution ranging

between 10 and 1800 lm, during the arc deposition of Ti-

Al-N coatings. In addition, the effect of cathode material

grain size on coating microstructure, composition, and

mechanical properties is discussed.

II. EXPERIMENTAL DETAILS

Classified by different average grain sizes distributions,

four grades of titanium–aluminum with equal atomic per-

centage were used in this study. The average grain sizes

were 1800, 100, 50, and 10 lm and they were labeled as

1800 lm-grade, 100 lm-grade, 50 lm-grade, and 10 lm-

grade, respectively. Monosized powder mixtures of Ti and

Al were prepared by sieving to the right grain size and used

as starting material during cathode manufacturing. All four

grades were fabricated in the same manner, i.e., densification

of the powder mixture by pressing and forging followed by

solid state sintering at 400

C. This fabrication route resulted

in a solid material with a density greater than 99.7% of theo-

retical density and below 300 lg/g of oxygen content.

In order to study the arc events on the virgin material,

pieces with dimensions 1.5 1.5 0.5 cm

3

were cut by a

diamond blade from all four grades. These pieces were then

polished to a mirror like finish by following the series of

grinding, lapping, and polishing steps. The pieces were then

cleaned in an ultrasonic ethanol bath. Each piece was fas-

tened with electrically conducting silver containing glue on

the surface of a dummy cathode [shown in Fig. 1(a)]. The

triggering event serves a dual purpose, one being the initia-

tion of the arc and the other being that the mechanical force

imparted by the trigger on the piece breaks free the estab-

lished electrical contact between the piece and the dummy

cathode. This ensures that the arc traverses the surface of the

piece only once (single trigger event). An industrial arc

chamber (Metaplas MZR323) was used for all the experi-

ments. The parameters used during the arcing of the pieces

were 2.0 10

6

Pa base pressure, 4.5 Pa nitrogen pressure,

and 80 A arc current.

To capture the surface state after multiple arcing events

(steady state arcing) and to analyze differences in the result-

ing coatings, full sized circular cathodes having a diameter

of 63 mm were also made from all four grades. These

cathodes were arced in N

2

(reactive) ambience with the

parameters of 2.0 10

6

Pa base pressure, 4.5 Pa N

2

pres-

sure, 30 V bias voltage, 75 A arc current, 300

C process

temperature, and a constant evaporation time is achieved by

a predetermined setpoint of 300 Ah. Coatings were deposited

on polished and ultrasonically cleaned WC-13 wt. % Co sub-

strates (ISO SNUN120408, 1.2 1.2 0.5 cm

3

) mounted on

a drum fixture rotating with a speed of 3 rpm as shown in

Fig. 1(b). Seven substrates were mounted such that they cov-

ered an angular range of 0

to 49

from the surface normal

of the cathode. Prior to the deposition of coatings, the sub-

strates were etched with Ar ions.

The microstructures of virgin and arced material, as well

as the coatings, were investigated using a LEO 1550 SEM

equipped with an Oxford energy dispersive x-ray spectrome-

ter (EDX). An acceleration voltage of 10 kV at a working

distance of 5 mm was used for imaging, while an acceleration

voltage of 20 kV at a working distance of 8.5 mm was used

for elemental mapping and compositional analysis. A TiAlN

sample of known composition was used to obtain calibrated

EDX data, resulting in an accuracy of the compositional

analysis of 5 at.%. For viewing the microstructure of the

converted layers by SEM, cross-sectional samples having

dimensions of 1 0.5 0.5 cm

3

were cut by a diamond

blade. These samples were then embedded in a carbon based

resin and polished by using the same regimen mentioned

earlier.

A Zeiss 1540 EsB CrossBeam (FIB) was used to section

the cathode surface features to reveal their microstructure.

The macro-particle areal density of the coatings was mea-

sured by the box-counting method, i.e., by dividing SEM

micrograph with an area of 2015 lm

2

into 60 boxes and then

counting the macro-particles in each box. The number of

macro-particles counted from 60 boxes was then divided by

the area of micrograph to calculate the areal density of

macro-particles. The lower limit on the radii of countable

macro-particles was set at 50 nm. Four micrographs from dif-

ferent locations along the diagonal of each coated substrate

were used to gain a reliable average macro-particle areal

density.

X-ray diffractometry of arced pieces, arced cathodes,

and coatings was performed in 1

grazing incidence geome-

try

16

using a PANalytical Empyrean diffractometer and

Cu-Ka radiation. Young’s modulus of 429 GPa and

FIG. 1. (a) Schematic drawing of how

a piece of Ti-50 at.% Al is glued to

the surfaces of a dummy cathode. (b)

Schematic drawing of the deposition

geometry showing how the cathode,

drum fixture, and the substrates were

positioned (not to scale).

245309-2 Syed et al. J. Appl. Phys. 121, 245309 (2017)

Poisson’s ratio of 0.19, as indicated by Mittemeijer et al. for

TiN

0.98

,

17

were used to measure the stress of the coatings by

using the sin

2

w method.

16

The hardness of the coatings was evaluated by using a

diamond Berkovich tip mounted on a load-controlled UMIS

nanoindenter. The area function of the tip was calibrated

using a fused silica reference sample. The hardness measure-

ments were obtained from load-displacement curves by

employing the method developed by Oliver and Phar.

18

The

hardness values reported were averaged from 40 indents at

25 mN load with a maximum achieved penetration depth of

0.18 lm on tapered (tapering angle 5

)

19

and polished cross

section of the coatings. The load of 25 mN and taper polish-

ing were used to mitigate the influences from the substrate

and surface roughness on the recorded hardness.

III. RESULTS

Figure 2 shows SEM micrographs of polished virgin

materials prepared from four grades. The grain size evalua-

tion by the tangent rule performed on theses micrographs is

in agreement with the result of the sieve analysis, suggesting

limited or no grain growth during manufacturing. Figure 3

shows the x-ray diffractograms of polished virgin materials

of all the four grades, showing that the virgin material of all

four grades has a duplex structure of two phases: Al and Ti.

The traces of the arc on polished pieces of four different

grades are shown in Fig. 4. In general, Al grains suffer more

erosion than Ti grains, and the largest craters tend to appear

at the shared peripheries of Ti and Al grains. The higher

erosion rate of Al is expected since Al compared to Ti has

a lower work function as well as cohesive energy. The

reported work functions of Ti and Al ranges from 4.33 to

4.53 eV (Refs. 1, 20,and21) and 4.08 to 4.28 eV,

1,20,22

respectively. In the case of Ti-Si,

9

Zhu et al. has shown that

the phase with a low work function experiences a higher fre-

quency of cathode spot events. The reported cohesive energies

of Ti and Al are 4.86 eV/atom (Ref. 23) and 3.34 eV/atom,

23

respectively. It has been established that, in general, cohesive

energies of metals have an inverse relationship with the ion

erosion rate.

24

On the 1800 lm-grade, the largest crater appears on an

Al grain and in close proximity of a Ti grain, and the diame-

ter of this crater is around 850 lm, while the largest crater on

a Ti grain is around 43 lm. An additional feature appears on

this grade in the form of macro-bubbles (solidified bubbles)

of Al located at the interface between the Ti and Al grains,

as shown by the overlaid EDX elemental map in Fig. 5(a).

Figure 5(b) shows the FIB excavated cross-section of the

macro-bubble, confirming that these features are hollow.

For the 100 lm-grade, the recorded diameter of the larg-

est craters on Al and Ti grains are approximately 18 and

2 lm, respectively. For the 50 lm-grade, the channels of Al

sandwiched between Ti grains suffer higher erosion, the cra-

ters left at this channel site encompass the Al channel as well

as the edges of the Ti grains. The largest crater of such kind

has an approximate diameter of 27 lm, while the largest cra-

ter left on the Al and Ti grains have diameters of around

5 lm and 2.5 lm, respectively.

FIG. 2. SEM micrograph of virgin

material (a) 1800 lm-grade, (b) 100 lm-

grade, (c) 50 lm-grade, and (d) 10 lm-

grade.

FIG. 3. X-ray diffractograms of all four grades of virgin material.

245309-3 Syed et al. J. Appl. Phys. 121, 245309 (2017)

The erosion on the 10 lm-grade appears to be more pro-

nounced compared to both the 100 and 50 lm-grades. The

largest observable crater on the 10 lm-grade has an approxi-

mate diameter of 35 lm. For the 10 lm-grade, the virgin

material [see Fig. 2(d)] consists of Ti grains with a diameter

smaller than 5 lm dispersed in the Al matrix. There appear

to be abundant craters of diameters greater than 5 lm. This

widespread dispersion of small Ti grains and abundance of

craters larger than Ti grains makes it impossible to ascertain

the diameter of largest craters on the Ti and Al grains.

The phase compositions of all the pieces after being arced

with a single trigger event are shown in the x-ray diffractro-

grams in Fig. 6. These diffractograms show that during the

initial stage of arcing the 1800 lm-grade retains its virgin

composition of Ti and Al, the 100 lm-grade also shows the

existence of just virgin phases, the 50 lm-grade shows the

additional trace of f (Al

5

Ti

2

), and the 10 lm-grade addition-

ally contains the intermetallic phase g (Al

2

Ti). Although

the ambient gas during the single trigger event was N

2

,no

N-containing compounds were detected.

The optical image in Figs. 7(a)–7(d) shows the virgin

and worn cathodes of all the four grades. The roughness of

arced cathodes can be seen to decrease from the 1800 lm-

grade to 50 lm-grade and then increase for the 10 lm-grade.

SEM micrographs of the topography of the converted layers

are shown in Figs. 7(i)–7(iv). The converted layer on the

1800 lm-grade hosts craters with diameters ranging from

sub-micron to 3100 lm. This converted layer is enriched

with craters of 2000 lm diameter. The crater diameters on

the converted layer of 100 lm-grade range from sub-micron

to 62 lm. The converted layer on the 50 lm-grade hosts cra-

ters as well as hole-like features. The diameters of the craters

range from sub-micron to 70 lm. The average diameter of

the hole-like features in the converted layer of the 50 lm-

grade is 25 lm, and these hole-like features occasionally

have sub-holes. The diameters of the craters on the converted

layer of the 10 lm-grade range from sub-micron to 22 lm

and the frequently occurring hole-like features are larger

FIG. 4. SEM micrograph showing arc

traces from a single trigger event on

(a) polished 1800 lm-grade, (b) pol-

ished 100 lm-grade with an inset show-

ing a magnified micrograph of Ti grain,

(c) polished 50 lm-grade (* denote the

regions of arced Al sandwiched

between Ti grains), and (d) polished

10 lm-grade.

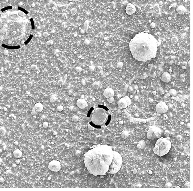

FIG. 5. (a) Scanning electron micro-

graph of macro-bubble with an EDX

elemental map. (b) The excavation of

macro-bubble achieved by Fib.

FIG. 6. X-ray diffractograms of all four grades after a single trigger event.

245309-4 Syed et al. J. Appl. Phys. 121, 245309 (2017)