52 citations

6 citations

2 citations

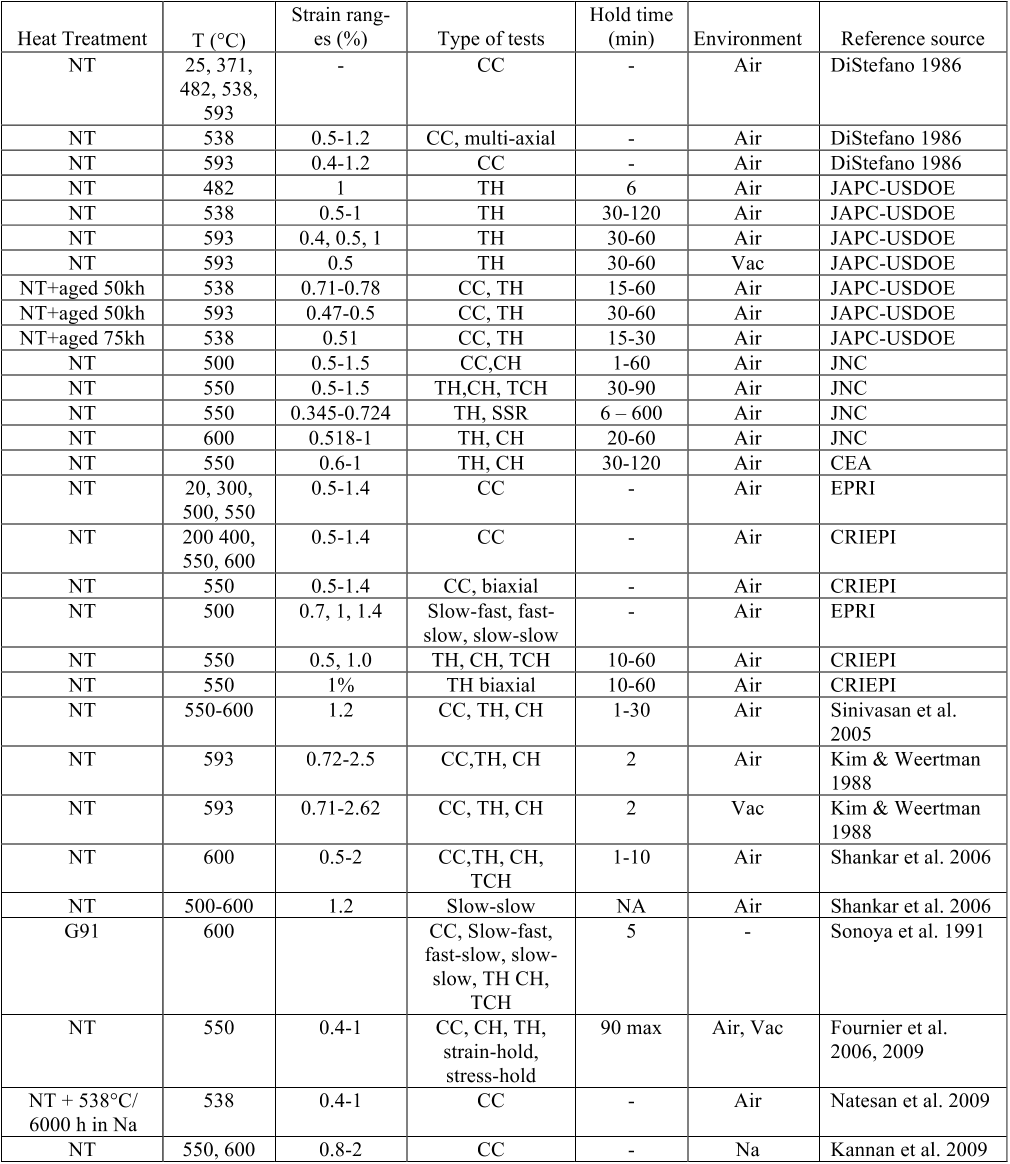

...A list of key technical issues was identified and a viable approach to resolve these issues and the R&D priority were recommended [Natesan et al. 2009]....

[...]

1 citations

1 citations

5 citations

...3 heats of plates 482-704 5,000-75,000 Tensile and impact Brinkman et al. (1990) 3 heats of plates 482-704 5,000-75,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) Tubing 552 130,000 Tensile test (20-650°C) Swindeman et al. (2000) Tubing 552 130,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) P91 625, 650 1000; 3000; 10,000 Tensile and impact Cumino et al....

[...]

...3 heats of plates 482-704 5,000-75,000 Tensile and impact Brinkman et al. (1990) 3 heats of plates 482-704 5,000-75,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) Tubing 552 130,000 Tensile test (20-650°C) Swindeman et al. (2000) Tubing 552 130,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) P91 625, 650 1000; 3000; 10,000 Tensile and impact Cumino et al. (2002) Boiler tube 116,000; 143,000 Swindeman (2001) P91 650 10,000 Creep (600°C/100-250 MPa) Sklenicka et al. (2003) P91 500-600°C 500 – 10,000 Microstructure Paul et al. (2008) Heat 30394 593 5000 Fatigue at 593°C Kim and Weertman (1988) P91 650 10,000 Microstructure Sanchez-Hanton and Thomson (2007) Mod....

[...]

...3 heats of plates 482-704 5,000-75,000 Tensile and impact Brinkman et al. (1990) 3 heats of plates 482-704 5,000-75,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) Tubing 552 130,000 Tensile test (20-650°C) Swindeman et al. (2000) Tubing 552 130,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) P91 625, 650 1000; 3000; 10,000 Tensile and impact Cumino et al. (2002) Boiler tube 116,000; 143,000 Swindeman (2001) P91 650 10,000 Creep (600°C/100-250 MPa) Sklenicka et al. (2003) P91 500-600°C 500 – 10,000 Microstructure Paul et al....

[...]

...3 heats of plates 482-704 5,000-75,000 Tensile and impact Brinkman et al. (1990) 3 heats of plates 482-704 5,000-75,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) Tubing 552 130,000 Tensile test (20-650°C) Swindeman et al. (2000) Tubing 552 130,000 Creep (550-625°C/100 MPa) Swindeman et al. (2000) P91 625, 650 1000; 3000; 10,000 Tensile and impact Cumino et al. (2002) Boiler tube 116,000; 143,000 Swindeman (2001) P91 650 10,000 Creep (600°C/100-250 MPa) Sklenicka et al....

[...]

...3 heats of plates 482-704 5,000-75,000 Tensile and impact Brinkman et al. (1990) 3 heats of plates 482-704 5,000-75,000 Creep (550-625°C/100 MPa) Swindeman et al....

[...]

3 citations

3 citations

2 citations

1 citations

...The reduction factor in fatigue life is 1.5 (Booker and Majumdar 1982)....

[...]

...Creep rupture tests were carried out at 566°C. Booker and Majumdar (1982) reported the effects of thermal aging on the fatigue proper- ties of 2.25Cr-1Mo steel....

[...]