HAL Id: hal-00004542

https://hal.archives-ouvertes.fr/hal-00004542

Submitted on 22 Mar 2005

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of sci-

entic research documents, whether they are pub-

lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diusion de documents

scientiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Shrinkage of the Gelatinous Layer of Poplar and Beech

Tension Wood

Bruno Clair, Bernard Thibaut

To cite this version:

Bruno Clair, Bernard Thibaut. Shrinkage of the Gelatinous Layer of Poplar and Beech Tension Wood.

IAWA Journal, Brill publishers, 2001, 22, pp.121-131. �10.1163/22941932-90000273�. �hal-00004542�

SHRINKAGE OF THE GELATINOUS LAYER OF

POPLAR AND BEECH TENSION WOOD

by

Bruno Clair & Bernard Thibaut

LMGC – Bois, Université Montpellier II, CC 081, Place E. Bataillon,

34095 Montpellier, France (e-mail: clair@lmgc.univ-montp2.fr).

Published in IAWA Journal, Vol. 22 (2), 2001: 121–131

SUMMARY

Macroscopic longitudinal shrinkage in beech or poplar tension wood

is higher than in normal wood. This shrinkage is the result of cell

walls layers mechanical interactions. In order to complete the basic

data with a view to modelling the cell wall, we are interested in

shrinkage differences between cell wall layers and especially of G-

layer in poplar and beech. Wood samples in green condition are cut

with a razor blade, and then dried before observation. SEM

observation shows longitudinal shrinkage much more important in

gelatinous layer than in other layers. AFM topographic images of

same cells, both in water and in air-dry conditions, confirm this result.

Measurements on thin sections allow quantitative results around 4.7 %

longitudinal shrinkage for G-layer.

Key words: cell wall, gelatinous layer, shrinkage, tension wood.

INTRODUCTION

Longitudinal shrinkage in wood

Like all other wood properties, hygroexpantion presents a very important

anisotropy. Between green condition and ovendry condition, shrinkage ranges from

0.05 % to 0.3 % in longitudinal direction, 3 % to 6 % in radial direction and from

6 % to 12 % in tangential one (Skaar 1988). According to these values, the

hygroexpension in axial direction is not apparently a problem for the user. However,

two cases exist when longitudinal shrinkage starts to be more important: in reaction

wood (tension wood of angiosperms and compression wood of gymnosperms) and

juvenile wood (Skaar 1988). In these two types of wood, axial shrinkage can reach

1 % or more (Nepveu 1994). For these woods, shrinkage value cannot be considered

as negligible, because wood beams have generally their longer distances in axial

direction. These important differences can be explained by the wood fibre structure.

2 IAWA Journal,

From wood fibre structure to shrinkage modelling

The knowledge of the wood cell structure, as a multi-layer fibre composite, allows

the modelling of the longitudinal shrinkage.

One of the first models, which is still a reference, is the Barber and Meylan 's

one (1964) refined by Barber (1968). This model considers that the cell wall is

reduced to S

2

layer. S

2

layer is described like an amorphous hygroscopic matrix in

which are imbedded parallel crystalline microfibrils which act to restrain

hygroexpention in the direction parallel to their axes (Fig. 1) (Cave 1972a). Thus,

microfibril angle is the determinant factor of longitudinal shrinkage. Low angle of

microfibril in relation to axial direction induces low axial shrinkage (like in normal

wood) and high angle allows a higher shrinkage (like in juvenile or compression

wood). Later, other models integrating other components properties (cellulose,

hemicellulose and lignin), changes in matrix behaviour during drying and

introducing the different cell wall layers have been proposed to refine this first

theory (Barrett et al. 1972; Cave 1972b, 1978; Sassus 1998; Gril et al. 1999;

Yamamoto 1999).

Matrix Microfibrils Woody mater

Fig. 1: schematic representation of the "reinforced matrix" (Sassus 1998)

These models give a good understanding of macroscopic axial shrinkage for

different values of microfibril angle, for normal, compression and juvenile wood.

However, they cannot explain the behaviour of tension wood with gelatinous

layer. In fact, in G layer, microfibril angle is very low or nil (Chaffey 2000), even

when macroscopic longitudinal shrinkage is high (Clarke 1937; Chow 1946; Sassus

1998). Norberg and Meier (1966) had isolated portion of G layer and said that they

do not show high longitudinal shrinkage. The G layer is generally loosened from S

2

layer and this latter one is very thin in tension wood. So these authors and Boyd

(1977) assume that in that case, longitudinal shrinkage is produced by S

1

layer, G

layer being unable to prevent it.

MATERIAL AND METHODS

One poplar (Populus cv I4551) and one beech (Fagus sylvatica L.), were chosen for

this study. These species are known to have characteristic tension wood with G layer

and a high macroscopic axial shrinkage.

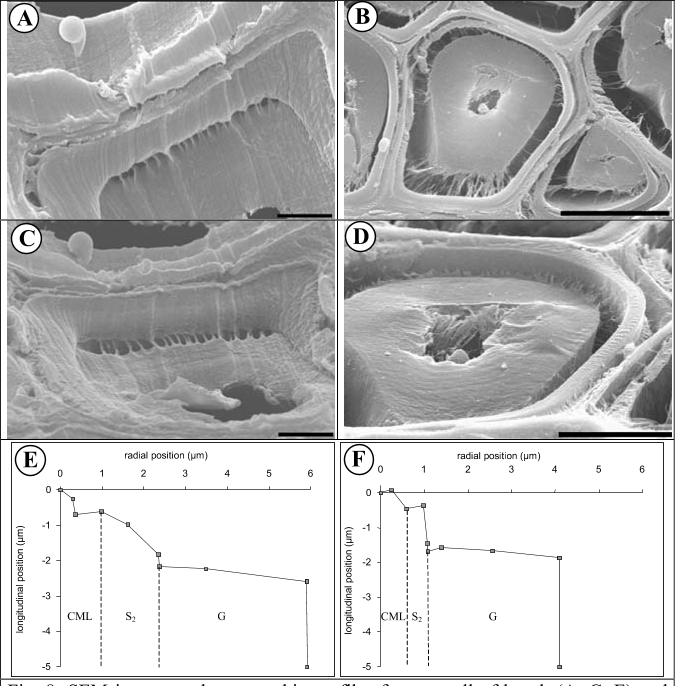

Populus cv I4551

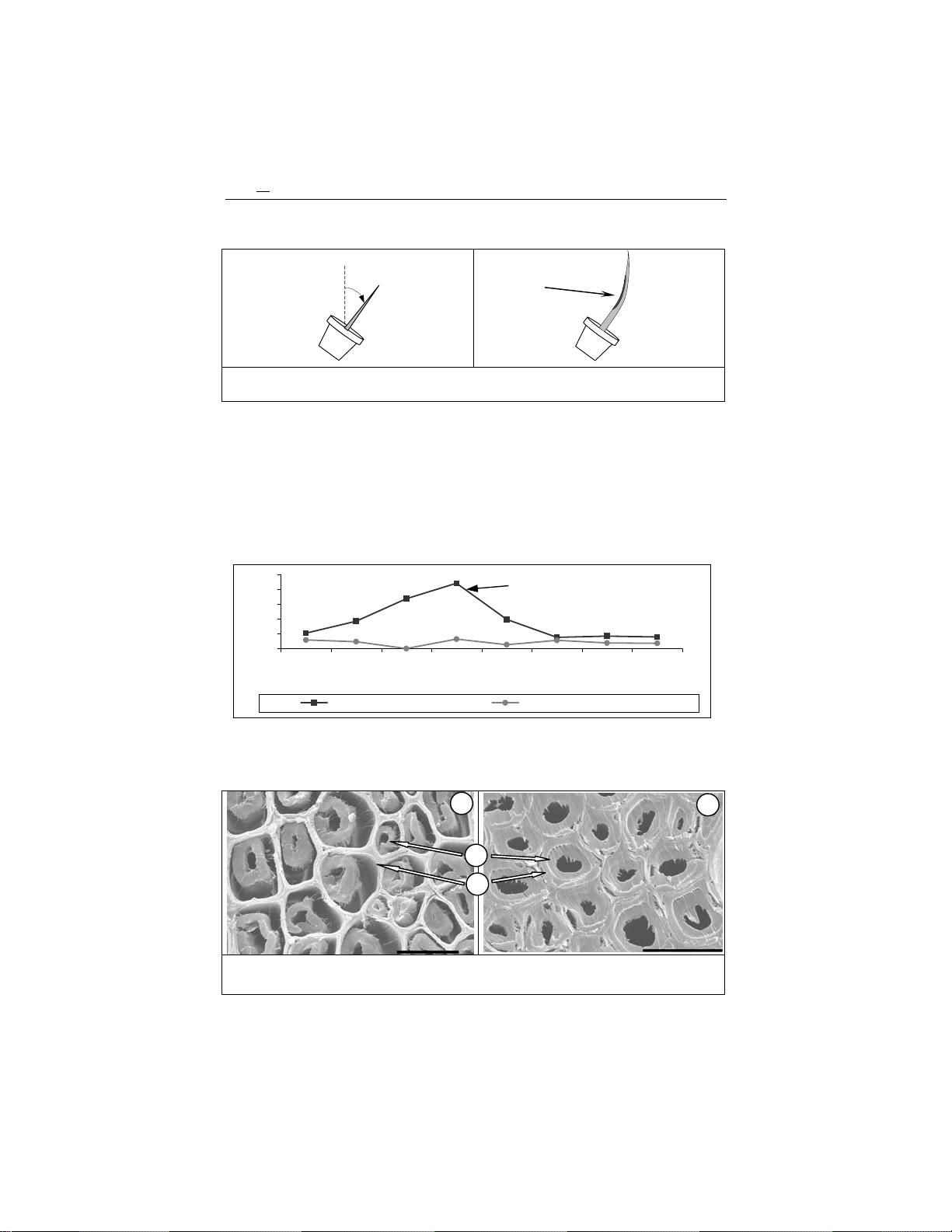

During the growing period, a young one year old poplar tree in a container is tilted

35° from the vertical. At the end of that period, the stem has nearly regained its

verticality by producing tension wood on the upper side (Fig. 2). Wood sample

taken from this tension wood zone have characteristic anatomical features

presenting a large amount of fibre with G layer and very thin S

2

layer (Fig. 4 A).

Clair G layer shrinkage 3

35°

Fig. 2: Recovery of the verticality of a poplar stem after the container have been

tilted 35°. Tension wood is produced on the upper side.

Fagus Sylvatica (L.)

A 150 years old tree was chosen after measurement of peripheral growth stresses at

breast height level on the standing tree, on eight positions around the trunk. This tree

was typical of a strongly dissymmetrical distribution of growth stresses (Fig. 3). A

high local level of growth stress is always related to presence of tension wood

(Trénard & Guéneau 1975; Sassus 1994). Wood sample were taken around the

highest values of growth stress (Z position on Fig. 3). In spite of large G layer in the

fibre cell wall, S

2

layer remains thicker than in poplar wood (Fig. 4 B).

0

50

100

150

200

250

0 45 90 135 180 225 270 315

angular position of trunk periphery (in degree)

DRLM (µm)

selected beech typical low stressed beech

II

I

Z

Fig. 3: Growth stress measurement on standing beech tree, on 8 angular positions of

trunk periphery. I: tree with regular low levels of growth stress, II: tree with a zone

(Z) of very high tensile growth stress.

Fig. 4: SEM observation of poplar (A) and beech (B) with gelatinous layer (G)

(also indicated S

2

layer) (Scale bar: 20 µm)

Tension

Wood

A

B

G

S

2

4 IAWA Journal,

Wood samples were stored in green condition before further processing into small

blocks or thin sections.

Massive blocks

Wood sticks (2 cm in longitudinal direction, section 5 x 5 mm²)

are cut up by splitting in order to guarantee a good axial direction. Sticks were then

cut to obtain 5 mm size cubes. Finally a last superficial planning is done manually

with a brand new razor blade in order to produce a nice transverse surface, the

sample being always kept in moist condition.

Thin sections

Transverse sections, 80 µm thick, were cut under water drop with a

microtome equipped with disposable razor blade. These sections were glued on the

edge with fibre direction parallel to support, in order to allow observations on

transverse sections on both sides of the sample.

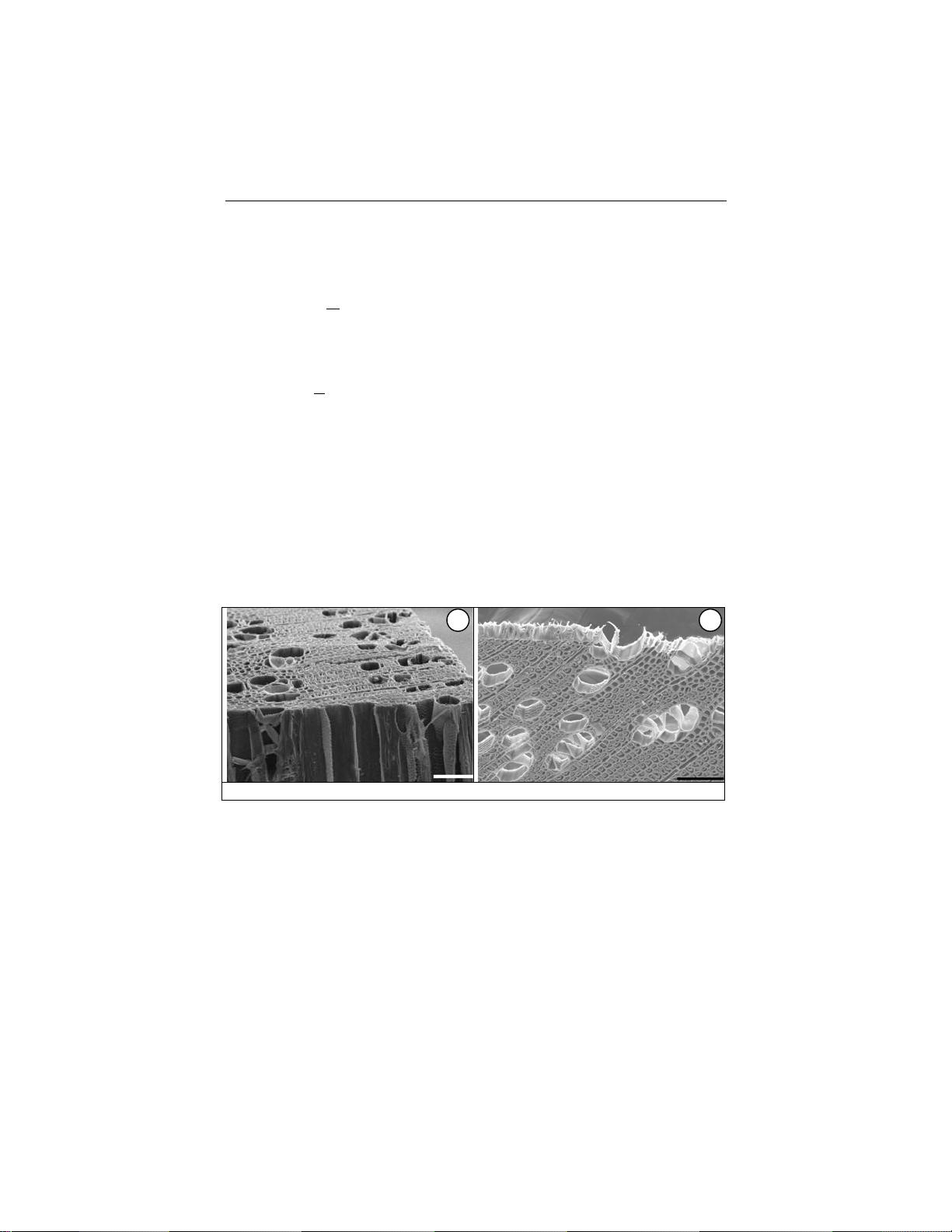

Scanning electron microscopy

Massive blocks or thin sections are dehydrated with absolute ethanol, passed to

critical point and coated (300 Å of platinum) before observation. Thus, observations

are made in oven dry condition with a Cambridge S360 Scan Electron Microscope

(Fig. 5).

The tilting of receptor allows to obtain images of a same object for different view

angles.

Fig. 5: SEM images of poplar: A massive bloc, B thin section; scale bars: 100 µm.

Atomic force microscopy

Smaller massive blocks (500 x 500 x 500 µm

3

), prepared the same way as before,

are observed in their transversal section in water and in air-dry condition. Four states

are studied: green condition, green condition after 2 hours in 80°C water, air-dry

conditions, wet conditions after air-drying. Atomic Force Microscope (Dimension

3100, Nanoscope IIIa, Digital Instruments) was used to obtain topographic images

of a 50 x 50 µm² area (around 10 cells). The same cells are observed successively in

these conditions (Fig. 6).

A B