Met. Mater. Int., Vol. 17, No. 1 (2011), pp. 00~00

doi: 10.1007/s12540-010- Published 26 February 2011

Study of Compaction and Ejection of Hydrided-Dehydrided

Titanium Powder

P. G. Esteban

1

, Y. Thomas

2

, E. Baril

2

, E. M. Ruiz-Navas

1

, and E. Gordo

1,

*

1

Department of Materials Science and Engineering, IQMAAB, University Carlos III ofe Madrid,

Avda. de la Universidad 30, 28911 Leganés (Madrid), Spain

2

Industrial Materials Institute (IMI), National Research Council Canada (CNRC–NRC),

75 de Mortagne Boulevard, Boucherville (Quebec), J4B 6Y4, Canada

(received date: 2010 / accepted date: 2010)

Three similar varieties of pure Ti hydride-dehydried (HDH) powders were tested for the understanding of

the variables that have an influence on the compaction process of Ti powders. The study shows that small

differences in the characteristics of the powders lead to very different behaviours in the compaction stage.

Compressibility curves, friction with the die walls and ejection forces are discussed in this study. The results

are compared with a commercial iron powder as a reference to complete the discussion, as well as to show

the enhancements and modifications that should be performed in Ti powders to design an optimized powder

suitable for being pressed in an industrial process.

Keywords: titanium hydride-dehydried(HDH), uniaxial pressing, compressibility

1. INTRODUCTION

The excellent combination of specific strength and corro-

sion resistance of titanium and titanium alloys [1,2] encour-

ages the development of low cost processes to obtain Ti

parts. Moreover, some studies [3] predict the decrease of the

prices of Ti due to new production techniques for obtaining

Ti from its ores. Among these new techniques, the Arm-

strong process [4] is ready for production, and other incom-

ing developments based on electrolytic methods could be

even more efficient in obtaining Ti at low cost. Among the

electrolytic methods, the FFC development [5] seems to be

the most promising to obtain Ti powder by the direct reduc-

tion of TiO

2

. Other works [6,7] have studied the benefits that

Ti would provide in the reduction of emissions in vehicles.

This conjunction of factors encourages industry to develop

the powder metallurgy technology for Ti.

Powder metallurgy has provided a low-cost route for man-

ufacturing iron-based parts and the related processes are now

optimized since they have been studied for a long time. On

the other hand, Ti is emerging as a good candidate for being

processed by conventional powder metallurgy techniques,

but improvements should be done to reach the optimization

of the processes. Ti powder industry has been restricted to

high-added value applications where the cost of the materi-

als and processes are not fully optimized for large scale

productions. The traditional and potential applications

include military, sports, aerospace, medical and automo-

tive [8,9]. Biomedical applications are promising to con-

tinue the development of Ti technology, including PM

processing [10-13].

Few papers have studied the compaction of Ti powders

[14-18]. This work is focused on the different aspects related

to the uniaxial pressing of Ti powder in comparison with the

well-known behaviour of commercial iron powder. As it will

be shown in this study, the significant difference between

titanium and iron is reflected in their relative pressing perfor-

mances.

Regarding the type of Ti powder used for this study, the

Hydried-dehydried powder (Ti HDH) has been selected due

to the higher purity than sponge powder, and irregular shape

compared to atomised powder, providing better characteris-

tics for powder metallurgy processing. Ti HDH is a common

variety of Ti powder which is produced by the comminution

of Ti solids which have been previously embrittled. In a first

stage, Ti solids are heated into a furnace in a hydrogen atmo-

sphere. Then, the solids loose their natural ductility by

hydrogen embrittlement, leading to hydrided Ti. In a second

stage, hydrided Ti solids are easily comminuted to the desire

powder size. In a final stage, hydrided Ti powder must be

dehydried to recover its original ductility and properties.

This is achieved by heating Ti powder into a vacuum fur-

nace, where degassing of the material occurs.

*Corresponding author: egordo@ing.uc3m.es

©KIM and Springer

2 P. G. Esteban et al.

2. EXPERIMENTAL PROCEDURE

All experiments were carried out using hydride-dehydride

(HDH) titanium powders and water-atomized iron powder,

compacted with admixed lubricant or with die-wall lubri-

cant. Table 1 describes the type of powders tested, their supplier,

and the lubrication mode used in each case. In particular, two

batches of the similar powder (Ti, HDH process, < 75 µm)

sold under the same tradename were evaluated (Batch 1 and

Batch 2).

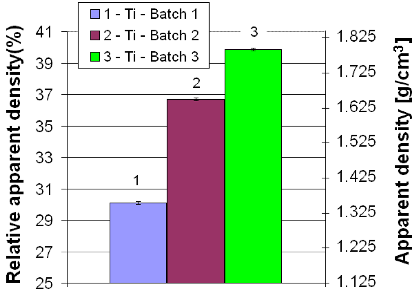

Apparent density was measured using the standards MPIF

4 and MPIF 28 [19,20]. Particle size distributions of the dif-

ferent powders were measured with a laser diffraction parti-

cle size analyzer (Beckman Coulter LS 13 320, USA).

Chemical analyses were carried out on LECO analyzers,

LECO TCH-600 for oxygen, nitrogen and hydrogen, and

LECO CS-200 for carbon and sulphur. Specific surface of

the powders was measured by the BET technique, using a

Monosorb Surface Area equipment, from Quantachrome

Corporation (USA), model MS-13.

Micro-hardness of the different powders was also evalu-

ated in a Vickers micro-hardness tester, model HVS-1000

(TIME Technology Europe). Ten HV

0.01

measurements were

carried out for each type of powder, at a load of 0.098N. The

same range of particle size was selected to better compare

the powders, and avoid size-effects in the measurements.

The behaviour of the different powders during compaction

and ejection was evaluated using an instrumented laboratory

press, the Powder Testing Centre (PTC) [21]. This apparatus

consists of an instrumented cylindrical die operating in a sin-

gle action mode. This press allows continuous recording of

the applied pressure and the pressure transmitted to the sta-

tionary punch during the compaction and ejection processes.

Assuming a rigid behaviour of the die, this press allows the

quantification of the three key properties or factors affecting

the green density, namely the friction at die walls, the pow-

der intrinsic compressibility and the expansion at ejection, as

described in the next section [22].

For all experiments, cylindrical specimens of 7 mm in

height were compacted at 500 MPa at room temperature in a

WC-Co die of 9.525 mm in diameter, and at a pressing rate

of 1 mm/s. At least seven samples were tested for each con-

dition, and the two first tests were used to condition the die

walls and were not considered for the calculations. Results

presented in this study show good reproducibility and corre-

spond to average values obtained from at least five specimens.

As described in Table 1, die wall lubrication was used to

minimize contamination of titanium. A thin layer of zinc

stearate was applied on the die walls using a semi-automated

device adapted to the PTC, based on the same principles of

the patented electrostatic system for industrial presses

[23,24]. In this system, lubricant particles are tribostatically

charged when they are carried by a flow of air through a

small Teflon tube, and are injected in the die cavity in such a

way to minimize turbulence. Excess of lubricant is evacu-

ated through exhaust vents located on the die cover plate. On

the other hand, iron powders were compacted either with

admixed lubricant or using die wall lubrication.

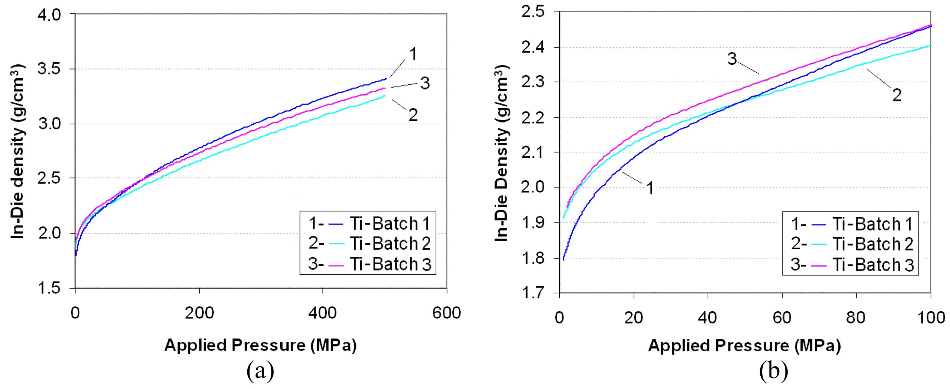

2.1. Analysis of the compaction process

The PTC enables to analyze the compaction process in a

rigid die as a function of two fundamental parameters: the

slide coefficient η, which measures the friction between

powder particles and die walls, and the intrinsic compress-

ibility, which measures the reaction of a powder to an out-

side pressure.

The intrinsic compressibility can be expressed by the rela-

tion between the average in-die density and the average pres-

sure seen by the compact. Considering that the density varies

linearly along the compaction axis as shown by several

researchers [25,26], it can be stated that the density at mid-

height is equal to the average density. Therefore, the average

pressure or net pressure, P

NET

can be evaluated at mid-height

of the compact with equation 1 for a cylindrical compact:

(1)

where Pa is the pressure applied to the compacting punch, Pt

the pressure transmitted to the stationary punch, η the sliding

coefficient, H the height of the compact, and D the diameter

of the compact.

It should be emphasized that the intrinsic compressibility

is only dependant on the intrinsic mechanical behavior of the

powder during compaction. On the other hand, the com-

pressibility, which is defined as the pressure required to

reach a given density or the density obtained for a given

P

NET

Pa*η

H

2D

-------

⎝⎠

⎛⎞

Pa*Pt()

12⁄

==

Table 1. Powders and lubrication used

Powder Supplier Mode of Lubrication Lubricant

Titanium Powders

Ti – Batch 1 GfE * Die-Wall Zinc Stearate

Ti – Batch 2 GfE* Die-Wall Zinc Stearate

Ti – Batch 3 GfE* Die-Wall Zinc Stearate

Iron Powders

ASC100.29 Höganäs** Die-Wall Zinc Stearate

ASC100.29 Höganäs** Admixed 0.7% EBS***

*GfE Metalle und Materialien Gmbh, Germany

**Höganäs, Sweden

***EBS: ethylene bisstearamide (ACRAWAX C from Lonza)

Study of Compaction and Ejection of Hydrided-Dehydrided Titanium Powder 3

pressure, is influenced not only by the powder intrinsic com-

pressibility but also by the friction at die walls and by the

expansion at ejection. In particular, the compact size or

aspect ratio strongly affects the amount of friction at the die

walls and therefore the compressibility, while the intrinsic

compressibility is, on the contrary, independent of the com-

pact aspect ratio.

The compaction process can also be described by the

determination of a slide coefficient η, which gives an evalu-

ation of the level of friction between powder particles and

die walls. The slide coefficient η characterizes the efficiency

of transferring the compaction force throughout the part and

the densification uniformity. The slide coefficient is given by

equation 2,

(2)

where Pa is the pressure applied to the compacting punch, Pt

the pressure transmitted to the stationary punch, F the cross-

section area, S the cross-section perimeter and H the height.

The factor 4F/SH represents the compact aspect ratio or

compact geometry factor. For a cylindrical compact, the fac-

tor 4F/SH is equal to D/H where D is the diameter of the

compact. η can vary between 0 and 1, 0 representing an infi-

nite friction and 1 no friction. Thus, the higher the η, the

lower the friction loss and the better the lubrication and den-

sification uniformity. For a given in-die density, the value of

the slide coefficient proved to be a good parameter to com-

pare the lubrication behavior of similar steel powder mixes

containing different types of lubricants[22,27, 28]. However,

the value of slide coefficient is far from being constant

through the pressing process. The variation of the slide coef-

ficient results, in fact, from the complex evolution of the fric-

tion coefficient and the angle of pressure transmission or

radial to axial stress ratio. However, at high pressures, the

relative movement of particles becomes negligible and the

slide coefficient varies mainly as a function of the friction

coefficient at die walls. The evolution of the coefficient of

friction and the stress ratio during compaction is discussed

elsewhere [29].

A complete ejection curve, as recorded by the PTC, is

shown in Figure 1. The stripping pressure corresponds to the

maximum ejection force, developed at the start the ejection

process divided by the friction surface area. The ejection unit

energy is defined, by the PTC developer, as the energy

required to move the compact from the 0.01 mm to the 2.55

mm punch position (area under the curve within this inter-

val) divided by the friction area of the test compact and by

the travel distance (2.54 mm). The unit is N*m/m

2

/m or J/m

3

.

3. RESULTS AND DISCUSSION

3.1. Particle size and morphology

Images of the iron and titanium powders used in this study

are shown in Fig. 2. The first difference that can be noticed

between Fe and Ti powders is their particle morphology.

Iron ASC100.29 has an irregular morphology, typical of

powder particles produced by water atomization. Among the

three Ti powders, Batch 2 and Batch 3 particles seem to be

more irregular in shape, while Batch 1 seems to be more

angular. The angular morphology of Ti powders derives

from the HDH process, in which titanium is hydrogenated in

order to make it brittle, which provides these fragile fracture

surfaces to the powder particles after milling. Then this pow-

der is dehydrogenated to be converted back to metal Ti and

the particles retain their angular morphology from the former

hydrogenated particles. The HDH process is a relatively

low-cost way to produce Ti powders with low oxygen and

low chlorine contents [30], which is essential to obtain the

highest mechanical properties of Ti.

Figure 3 shows the volume weighed particle size distribu-

η

Pt

Pa

------

⎝⎠

⎛⎞

4F

SH

-------

=

Fig. 1. Typical ejection curve and ejection characteristics measured.

Fig. 2. SEM images of the different powders. (a) Ti-Batch 1, (b) Ti–

Batch 2, (c)Ti-Batch 3, (d) Fe ASC100.29.

4 P. G. Esteban et al.

tions (left) as well as the cumulative volume particle size dis-

tributions (right) for all the powders tested. Batch 1 has a

slightly higher mean size and slightly wider distribution size

than Batch 2 and Batch 3 have approximately the same dis-

tribution shape, but displaced. Fe ASC100.29 shows a differ-

ent distribution shape, clearly wider than all the others. The

characteristic parameters extracted from the particle size dis-

tributions are summarized in Table 2.

3.2. Composition and hardness

In relation with the purity of the powders, it is known that

little content of interstitial elements (oxygen, carbon, nitro-

gen and hydrogen) contributes to dramatically change the

mechanical properties of titanium. These interstitials increase

the elastic modulus, the yield strength and reduce the ductil-

ity of titanium [31]. Nitrogen has generally the most signifi-

cant effect followed by oxygen and carbon [32,33]. While

nitrogen and carbon are usually not found at high concentra-

tions in dense titanium, oxygen is a common contaminant

due to the high affinity of titanium for oxygen and the high

solubility of oxygen in titanium. The total content of intersti-

tial, especially oxygen, is normally higher in the powder par-

ticles with the lower particle size due to their higher specific

surface. The analyses of these impurities have been deter-

mined for the four powders and are summarized in Table 3.

O

Eq

(%at) = O + 1.96*N + 0.52*C (3)[31]

Ti - Batch 1 and Batch 2 have very similar oxygen content,

but their nitrogen is significantly different, what is consistent

with the microhardness values. Indeed, the nitrogen content

of Batch 2 is about 10X higher than Batch 1 and the HV

0.01

of

Batch 2 is about 30 % higher than Batch 1. Conrad et al. [31]

proposed an equivalent oxygen equation to estimate the Vick-

ers hardness. In the equation 3, the effect of the nitrogen con-

tent is 1.96X that of oxygen and the carbon content is 0.52X

of oxygen. Table 3 gives the O

Eq

as calculated with the actual

composition of the powders. However, as showed in works

regarding mechanical properties of Ti foams [34], for high

specific surface materials, it is important to discriminate the

amount of oxygen coming from solid solution from that of

the surface oxide layer. As powder particles have a high spe-

cific area, the main part of oxygen is located as an oxide layer

at the surface of the particles, so this oxygen does not harden

the inside of the particles. Then, instead of total oxygen, only

the contribution of oxygen in solid solution (inside the vol-

ume of the particles) should be considered as a contributor to

the mechanical properties of the titanium powder.

Fig. 3. Particle size distributions (left), and cumulative distributions (right) for the four powders tested.

Table 2. Particle size characteristic parameters of the different

powders

Mean size

[µm]

D

10

[µm]

D

50

[µm]

D

90

[µm]

Ti - Batch 1 54 24 51 88

Ti - Batch 2 48 21 47 77

Ti – Batch 3 119 80 115 166

Fe ASC100.29 97 38 88 169

Table 3. Hardness and Chemical analyses of O, N, C and H for the four powders tested

Hardness

HV

0.01

Specific

surface [m

2

/g]

wt.% O wt.% N ppm H wt.% C

at.% O

Eq

(1)

(wt.%)

at.% O

SolEq

(2)

(wt.%)

Ti – Batch 1 127 ± 24 0.09 0.319 ± 0.003 0.008 ± 0.001 57 ± 2 0.009 ± 0.001 1.020(0.343) 0.543(0.182)

Ti – Batch 2 167 ± 32 0.1 0.343 ± 0.002 0.098 ± 0.004 106 ± 2 0.013 ± 0.002 1.693(0.572) 1.146(0.385)

Ti – Batch 3 159 ± 20 0.05 0.250 ± 0.006 0.069 ± 0.004 74 ± 2 0.013 ± 0.001 1.228(0.414) 0.955(0.321)

Fe ASC100.29 103 ± 16 0.02 0.083 ± 0.005 0.003 ± 0.001 4 ± 2 0.006 ± 0.001 - -

(1)

Total equivalent oxygen content (at.%) - see equation 3.

(2)

Equivalent oxygen calculated with interstitial in solid solution in the powder particles.