Temperature dependence of friction under cryogenic conditions

in vacuum

J. C. Burton, P. Taborek* and J. E. Rutledge

Department of Physics and Astronomy, University of California, 4129 Fredrick Reines Hall, Irvine, CA 92697, USA

Received 12 June 2006; accepted 21 July 2006; published online 26 August 2006

We have constructed a sliding block cryotribometer designed to measure friction at cryogenic temperatures and UHV

conditions. An optical cryostat and high speed video was used to monitor the motion of the block. The temperature range of the

measurements was 4–460 K. Both the static and dynamic friction coefficients were determined for a steel ball on stainless steel,

sapphire, and PTFE (Teflon) plates, and for a sapphire ball on a sapphire plate. For all material combinations, no systematic

variation of friction with temperature was observed in the temperature range 4–200 K.

KEY WORDS: cryotribology, friction test methods, static friction, PTFE, unlubricated wear

1. Introduction

Many thermodynamic and trans port properties of

solids depend dramatically on the temperature. Proper-

ties determined by phonons such as the heat capacity and

thermal diffusivity often differ by orders of magnitude

above and below the Debye temperature. In both metals

and semiconductors, the electrical resistivity can have a

strong temperature dependence, particularly in the

cryogenic regime. Since a fundamental description of

friction between solids involves electronic and phonon

coupling between the interfaces [1], it is of interest to

investigate whether the temperature dependence of the

scattering properties of the elementary excitations is

reflected in observable variation of the friction coeffi-

cients with temperature. More macroscopic theories [2]

of frictional phenomena use models based on effects such

as local melting of asperities, viscoelastic effects, plastic

flow, and tribochemistry [3]. The rates of these processes

have a strong Arrhenius-type temperature dependence,

with the local temperature determined by a balance of

heat generation at the surface and heat flow away from

the sliding surface. At sufficiently low temperatures, the

rate of thermally activated processes becomes vanish-

ingly small, and processes which are important at room

temperature ca n be effectively turned off. Another the-

oretical approach leads to a frictional force with an

additive term that is proportional to the temperature T

and to the logarithm of the sliding velocity [4, 5]. Thus,

from both the fundamental and the macroscopic phe-

nomenological point of view, temperature might be

expected to play an important role in sliding friction,

particularly in the cryogenic regime. Despite this theo-

retical expectation, there have been very few experi -

mental investigations of friction at low temperatures,

and the studies which do exist often involve surfaces in

contact with gases or cryogenic fluids [6–10] which

complicates the interpretation of the data in terms of

interfacial processes. Other experiments have used AFM

techniques to study friction at single asperities on well

characterized single crystal surfaces in vacuum [11].

The purpose of the measurements described here is to

provide a survey of friction behavior over a wide range of

temperature for materials of engineering importance. The

materials we have chosen, stainless steel, Teflon (PTFE),

and sapphire, are repres entative of metals, polymers, and

crystalline insulators whose electronic and mechani cal

properties span a wide range. Friction measurements on

macroscopic samples in vacuum at cryogenic tempera-

tures pose significant experimental challenges and require

special purpose tribometers. We have chosen a concep-

tually simple but rather unusual technique which involves

monitoring the motion of a block sliding down an

inclined plane using high speed video. The video frames

are analyzed to yield the acceleration and force on the

sliding block, from which the sliding friction coefficient

can be determined. The static friction coefficient is

obtained from the critical angle of inclination required to

initiate sliding. Cont rary to our initial expectations, our

results for the friction coefficients show very little tem-

perature dependence in the range 4–200 K. Reproducible

thermal effects wer e observed in the temperature range

200–400 K, but wear was found to be a more important

effect than temperature.

*To whom correspondence should be addressed.

E-mail: ptaborek@uci.edu

1023-8883/06/0800–0131/0 Ó 2006 Springer Science+Business Media, Inc.

Tribology Letters, Vol. 23, No. 2, August 2006 (Ó 2006) 131

DOI: 10.1007/s11249-006-9115-7

2. Experimental methods

Our tribometer consists of a 2cm 1.27cm 1.27cm

copper block which slides in a vee-shaped track

approximately 10 cm long. Two of the faces of the cop-

per block slider have three 3.175 mm (1/8 inch) diameter

balls made from bearing steel attached so that approxi-

mately half of the ball is exposed; these hemispherical

contact points support the load and define the tribolog-

ical contact points. In the limit of zero friction, five

contact points determine the orientation of the slider in

the track, so six contact points over constr ain the system.

The friction coefficients we measure, however, depend

only on the sum of the normal forces exerted by all of the

contact points, and not on the details of the force dis-

tribution. Most of our measurements were done with

steel balls, but one experimental run was done with

sapphire balls (purchased from Small Parts). The balls

make contact with two recta ngular plates mounted at

90 degrees which form the vee. The main body of the

track holder is made of OFHC copper for thermal

management reasons. The tracks are mounted in

machined recesses in the copper body of the track holder

and are replaceable; we used highly polished stainless

steel (McMasterCarr 304 ss mirror-like finish), sapphire

(Crystal Systems, 80–50 optical polish, unknown

crystallographic orientation) and PTFE coated steel

(Dupont 851–214Green PTFE coating 73 microns thick).

A schematic diagram of the slider is shown in figure 1.

The track holder is mounted on a frame which hangs

from the upper surface of a 4 K platform in a cryostat.

The holder is mounted on bushings which allow it to

rotate around a horizontal axis. Its angular position is

controlled by a wire attached to a linear feedthru at the

top of the cryostat. The entire tribometer is completely

enclosed by a copper radiation shield which is attached

to the 4 K platform. Optical access is provided by two

windows of infrared absorbing glass(Schott KG-1). The

4 K shield is inside a 77 K radiation shield which also

has infrared absorbing windows. The cryostat is

mounted in a conventional stainless steel vacuum tank

46 cm in diameter with quartz windows in Conflat ports,

as shown in figure 2. The design of the cryostat is similar

to other optical cryostats used previously in our labo-

ratory [12–14].

While the apparatus is at room temperature, it is

pumped out to a pressure of 10

)6

Torr. Once the radi-

ation shields of the cryostat reach their fina l tempera-

tures of approximately 4 and 77 K, respectively, the

region surrounding the tribometer is effectively cryo-

pumped by the shields, and the pressure presumably

drops to very low values. The temperature of the trib-

ometer is monitored and controlled independently of the

shields using a heater and thermometer attached to the

copper body of the vee-shaped track. Because of the

point-like contacts of the balls, the sliding block makes

poor thermal contact with the track; if this were the only

thermal connection to the track, the temperature of the

block would be impossible to control. To enhance the

thermal contact, a high magnetic permeability disk of

mu metal is attached at one end of the block which can

be attracted to the mu metal core of a solenoid at the

end of the track. The solenoid can hold the block at the

end of the track even when the track is tilted at a large

angle. When the current through the coil is switched off,

the block can slide freely.

Once the block and track have reached a thermal

steady state, the static and kinetic friction coefficients l

s

Figure 1. Schematic diagram showing copper slider supported on ball

bearings which slides on replaceable plates that form a 90 degree vee

track. The mu metal button is used in conjunction with the solenoid to

provide thermal contact to the copper slider and to control the release

of the slider at high inclination angles.

Figure 2. Schematic diagram of the cryostat and sliding block trib-

ometer. The vee-shaped track can be rotated around a horizontal axis

by pulling against a counterweight with a thin flexible wire attached to

a vacuum feedthrough. In the actual experiment, the camera and the

light source were collinear with the axis of rotation.

132 J.C. Burton et al./Temperature dependence of friction in vaccum

and l

k

can be determined by using the video camera to

monitor the motion of the block. The forces on the

block are illustrated in figure 3. l

s

is determined by

slowly increasing the angle of inclin ation h until motion

begins at h = h

0

. h

0

is measured from the video image.

At h

0

, the component of the gravitat ional force pulling

the block down the track mgsinh

0

and the frictional

force retarding the motion

ffiffiffi

2

p

l

s

mgcosh

0

are in balance,

so the static coefficient of friction is

l

s

¼

tanh

0

ffiffiffi

2

p

ð1Þ

The coefficient of kinetic friction l

k

is determined by

analyzing the video frames of the motion of the block as

it slides down the track. To avoid the stick-slip motion

characteristic of sliding near the critical angle, sliding

friction measur ements were performed by clamping the

block at the end of the track using the solenoid, inclining

the track at an angle approximately 10° higher than the

critical angle, and then releasing the block. The block is

illuminated from behind using a conventional photo-

graphic lamp. The infrared filters on the shields mini-

mize the heat load on the tribometer; the temperature is

observed to rise approximately 0.5 K when the lamp is

turned on near 4 K, and less than 50 mK at higher

temperatures. We used a Phantom V7.2 camera which

produces digital images with 512 384 pixels at a typical

frame rate of 1000 fps; the spatial resolution of the im-

age using our optics is 250 microns per pixel. The

camera was carefully mounted in the horizontal position

to within ± 0.1° using a digital level. A software

package written in Mathematica using standard convo-

lution techniques tracks the position of a corner of the

block from one frame to the next and produces a list of

positions as a function of time. The acceleration is

determined by constructing a least squares fit of a qua-

dratic polynomial to the trajectory; a typical example is

shown in figure 4.

The high quality of the quadratic fit indicates that, to

a good approximation, the block slides with constant

acceleration a that can be determined from the second

derivative of the the best fit polynomial. It also implies

that if there is a term in the fric tional force proportional

to the logarithm of the velocity, it must be very small for

the conditions of our apparatus. The coefficient of

kinetic friction is determined from

l

k

¼

tanh

ffiffiffi

2

p

a

g

ffiffiffi

2

p

cosh

ð2Þ

The statistical uncertainty in the value of l

k

obtained

from data like those shown in figure 4 using Equation 2

is remarkably small and is of the order of 10

)3

. Uncer-

tainty in the angle introduces a systematic error of

roughly the same amount.

3. Friction as a function of temperature

Friction measurements as described above were per-

formed using steel balls on three types of tracks: stain-

less steel, polished sapphire, and PTFE coated steel

shown in figures 5, 6 and 8, respectively. One run was

done using sapphire balls on a sapphire plate as shown

in figure 7. Each experimental run was started with a

new set of balls in the block and a fresh sample of the

track material. We found that the run-in history of the

samples strongly affected the friction. Each set of mea-

surements is denoted in the figures by colors and sym-

bols labeled ‘‘cooldown1’’, ‘‘cooldown2’’ , ‘‘warmup1’’,

‘‘warmup2’’, etc., which describe the thermal cycling as

well as the wear history of the sample. All of the

experimental runs were started with the tribometer and

the cryostat shields near room temperature and the

pressure at approximately 10

)6

Torr. For the hard

track materials, steel and sapphire, this first friction

Figure 3. Free body diagram showing the total forces on the sliding

block. The factors of

ffiffiffi

2

p

are due to fact that the load bearing faces of

the block are inclined at an angle of 45°, as shown in figure 1. The total

normal force is made up of the sum of the normal force exerted by each

face of the vee: mgcosðÞ

ffiffiffi

2

p

þ mgcosðÞ

ffiffiffi

2

p

¼

ffiffiffi

2

p

mgcosðÞ.

Figure 4. Displacement of the block parallel to the track as a function

of time. Open circles are the position determined from the video

frames. The solid curve is a least squares fit of a quadratic polynomial.

The coefficient of the quadratic term is directly related to the

acceleration.

J.C. Burton et al./Temperature dependence of friction in vaccum 133

measurement gave the lowest values we observed

throughout the sequence of measurements. Next, the

temperature of the cryostat shields was lowered to their

final values and simultaneously, the temperature of the

tribometer was raised to approximately 400 K. This

presumably has the effect of outgassing the tribometer

surfaces and cryopumping the apparatus. The temper-

ature of the trib ometer was then ramped several times

from approximately 400 K down to 4 K and back again,

and friction measurements were obtained at intervals of

approximately 20 K. A noteworthy feature of the data is

that although the statistical error in l obtained from a

single slide down the track was very small, the fluctua-

tions in l obtained from a series of measurements at the

same or similar temperatures was much larger.

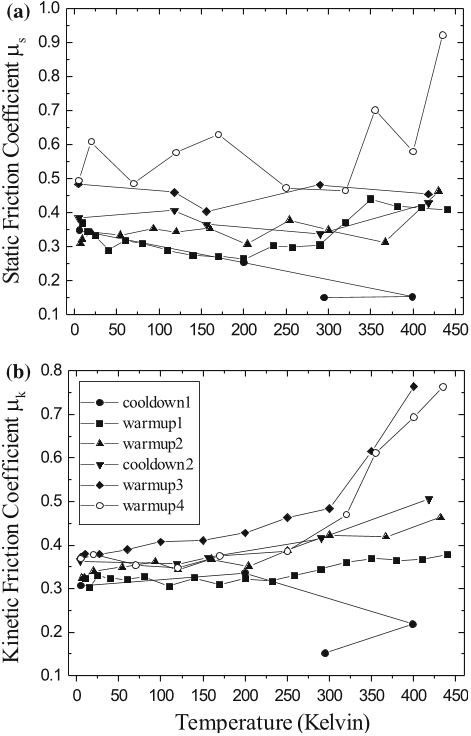

Our results for friction of steel on steel as a function

of temperature are shown in figure 5. The Hertzian

contact stress is computed assuming 5 balls are in con-

tact, and is approximately 232 MPa. At room temper-

ature, the kinetic friction coefficient l

k

is initially 0.15,

but during the first cooling cycle, it rises to approxi-

mately 0.3. We believe most of this change can be

attributed to the rapid wear that occurs in high vacuum

[15, 16]. l

k

increases very gradually over several cooling

and heating cycles, which is also presumably due to

wear. The only substantial temperature dependence

evolves after consider able wear, when the samples show

a reproducible and reversible increase from l

k

G0.4

to l

k

G0.8 in the range 300K < T < 450K. The static

friction coefficient l

s

qualitatively follows the same

pattern.

The friction data for steel on sapphire is shown in

figure 6. The Hertzian contact stress is approximately

276 MPa. The initial values of l

k

are approximately

0.15, but as the sample wears in, l

k

increases to the

range 0.4–0.45. There is very little temperature depen-

dence, particularly below 250 K. Above 250 K l

k

decreases slightly with temperature. The static friction

coefficient shows qualitati vely the same behavior. The

friction of sapphire on sapphire shown in figure 7 also

follows the same pattern: initially, the friction is very

(a)

(b)

Figure 5. Friction coefficients of stainless steel on stainless steel as a

function of temperature. The symbols indicate whether the data was

taken on heating or cooling, and the line segments connecting the data

points indicate the order in which they were measured. (a) static

friction, (b) sliding friction.

(a)

(b)

Figure 6. Friction coefficients of stainless steel on sapphire as a

function of temperature. The symbols indicate whether the data was

taken on heating or cooling, and the line segments connecting the data

points indicate the order in which they were measured. (a) static fric-

tion, (b) sliding friction.

134 J.C. Burton et al./Temperature dependence of friction in vaccum

low, but the wear caused by a few sliding cycles

increases l

k

to approximately 0.4, and it becomes

independent of temperature. These values are consistent

with previous measurements at room temperature in

vacuum [17].

The friction data for steel on PTFE is shown in fig-

ure 8. The Hertzian contact stress is approximately

2.64 MPa. Below 200 K, there is essentially no temper-

ature dependence of either l

k

or l

s

. In contrast to the

hard materials, the effects of wear appear to be minimal,

and the friction coefficient measurements show no sys-

tematic variation with the number of sliding cycles.

Between 250 and 450 K, there is significant and

repeatable temperature dependence which is hysteretic.

In contrast again with the hard materials, the kinetic

and static friction coefficients on PTFE show opposite

behaviors: the static friction coefficient drops by nearly a

factor of 5 from l

s

= 0.25 at T = 200 K to l

s

= 0.06

at T = 450 K, while the kinetic friction has a feature at

T = 370 K which is a maximum on warming and a

minimum on cooling. The position of the maximum and

minimum depend on the cooling and heating rate. The

characteristic relaxation time for the transition from one

state to another is approximately 3 h. This hysteretic

behavior may be due to a phase transition that is known

to occur in PTFE in the vicinity of 300 K [18, 19].

After the sliding measurements on each sample were

completed, the track was examin ed for evidence of wear.

Optical microphotographs are shown in figure 9. For the

steel-PTFE system, no particles were observed, and there

was no optically detectable transfer film on the steel ball,

but the track in the PTFE was visible, primarily due to an

increased reflect ivity; the track had a smooth appearance

with no apparent scratches. For the steel on steel system,

we observed clearly visible wear tracks which roughened

the mir ror-like finish of the sliding surfa ce. The track is

composed of many small scratches parallel to the direc-

tion of motion which are approximately 300 microns in

length. Both steel and sapphire balls on sapphire pro-

duced a visible track in the sapphire as well as numerous

fine white particles which were presumably sapphire. The

sapphire ball showed stress cracks and both the sapphire

and steel balls were covered with clumps of the fine white

particles.

(a)

(b)

Figure 7. Friction coefficients of sapphire on sapphire as a function of

temperature. The symbols indicate whether the data was taken on

heating or cooling, and the line segments connecting the data points

indicate the order in which they were measured. (a) static friction, (b)

sliding friction.

(a)

(b)

Figure 8. Friction coefficients of steel on PTFE (Teflon) coating as a

function of temperature. The symbols indicate whether the data was

taken on heating or cooling, and the line segments connecting the data

points indicate the order in which they were measured. (a) static

friction, (b) sliding friction.

J.C. Burton et al./Temperature dependence of friction in vaccum 135