read more

![Fig. 4. The predicted mass burning rate vs time and comparison between the predicted and measured [7] time-averaged distribution at the pool surface.](/figures/fig-4-the-predicted-mass-burning-rate-vs-time-and-comparison-17uamzsf.png)

![Fig. 7. Comparison between the predicted and measured [1] temperature profiles in the liquid at different locations for the heptane fire (z represents the vertical location from the fuel bottom).](/figures/fig-7-comparison-between-the-predicted-and-measured-1-12fj1ohf.png)

The puffing nature of pool fires creates unsteady inhomogeneous heat feedback, resulting in transient non-uniform distribution of the mass burning rate.

A total of 16 solid angles covering the hemisphere are used for the radiative transfer equations as a compromise between computational time and accuracy.

The most popular evaporation model to predict the burning rate in the literature is based on the ‘film theory’ where evaporation is driven by a diffusion process and liquid-vapour equilibrium is assumed at the pool surface temperature [18, 19].

The evaporation model used in this study follows the widely used ‘film theory’ model proposedby Sikanen and Hostikka [18], which is based on the liquid-vapour equilibrium assumption.

The Marangoni effect, resulting from the surface temperature gradient, is more pronounced at the heat-up stage, is expected to play a more important role for the transient burning rate.

the burning process of thin-layer pool fires is highly transient [9] while deep pool fires can reach a quasi-steady state after a warm-up period [6].

The ‘film theory’ based model is capable of capturing the transient nature of the burning processes by allowing for the evaporation below the boiling point.

The turbulent pool fire is simulated by the in-house version of FireFOAM [21], the LES basedfire simulation solver within open source CFD code, OpenFOAM.

The convective heat flux is much smaller than the radiative heat flux due to the relatively small flow velocity at the pool surface.

It can also be observed that the surface Marangoni velocity is directed from the hot region to the cold region, tending to reduce the temperature gradient on the pool surface and promote more uniform distribution of the mass burning rate compared to the neglection of the convective motion.

To resolve the gas flow at the pool surface, the meshes inside the burner lips are refined with a 1 mm cell size in the vertical direction, which corresponds to 𝑌+ < 1.5.

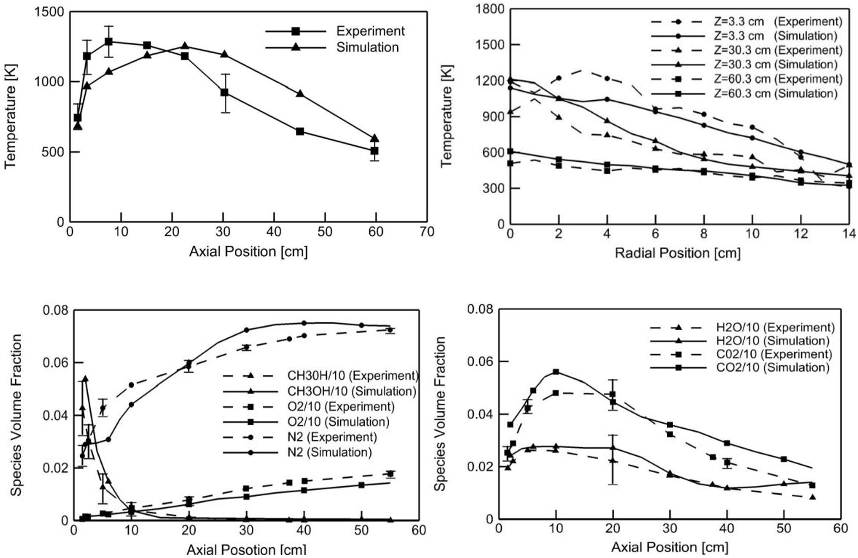

The temperature profiles at the top two locations are apparently under-predicted by the simulation without convection, and over-predicted at the bottom two locations due to the over-prediction of the mass burning rate as mentioned above.

From 50 s onwards, the measured burning rate remained almost constant, while the predicted value continues to increase gradually.

The burning rate remains unchangedprior to 12 s during the numerical ignition process due to the relatively low radiative heat feedback, and then increase quickly to a quasi-steady value of 0.013 𝑘𝑔 (𝑚2 ∙ 𝑠)⁄ at 30 s.

Liquid pool fires are often present in accidental fire scenarios in the process industry resulting from fuel spills and storage tanks.

a moving boundary was set for the pool surface to allow for the surface regression for the transient thin-layer case, while the pool surface was fixed for the steady deep pool fire during the simulations.

To initiate the evaporation process, the simulations started from an initial burning rate of 0.003𝑘𝑔/(𝑚2 ∙ 𝑠) which was found to be the lowest initial rate to achieve a quick ignition.

Very recently, Fukumoto et al. [20] numerically investigated the vortex motions of a steady small-scale methanolpool fire, using fully compressible description for the liquid pool.

5. The convective motion is more significant for the heptane fire than the methanol fire due to the relatively larger radiative heat feedback.

This might have been caused by the increase in the container lip height due to the regression of the pool surface in the experiments, which would affect the magnitude of the mass burning rate as found by Dlugogorski and Wilson [24].