'83@/<=3>C90(966981981'83@/<=3>C90(966981981

$/=/+<-2"8638/$/=/+<-2"8638/

+-?6>C908138//<381+8.809<7+>398

%-3/8-/=#+:/<=#+<>

+-?6>C908138//<381+8.809<7+>398

%-3/8-/=

&2/9:>373=+>39890>2/=/-98.+<C-996381A+>/<.3=><3,?>398A3>237:<9@/.&2/9:>373=+>39890>2/=/-98.+<C-996381A+>/<.3=><3,?>398A3>237:<9@/.

1/8/>3-+619<3>2738-98>38?9?=-+=>38190=>//6=1/8/>3-+619<3>2738-98>38?9?=-+=>38190=>//6=

)?2?8*2+3

!9<>2/+=>/<8'83@/<=3>C

)3813

!9<>2/+=>/<8'83@/<=3>C

/3C?/ +

!9<>2/+=>/<8'83@/<=3>C

)+8

!9<>2/+=>/<8'83@/<=3>C

*2/81C33+81

'83@/<=3>C90(966981981

43+81?9A/.?+?

9669A>23=+8.+..3>398+6A9<5=+>2>>:=<9?9A/.?+?/3=:+:/<=

#+<>90>2/8138//<38197798=+8.>2/%-3/8-/+8.&/-289691C%>?.3/=97798=

$/-977/8./.3>+>398$/-977/8./.3>+>398

*2+3)?2?83)381 +/3C?/)+8+8.3+81*2/81C3&2/9:>373=+>39890>2/=/-98.+<C-996381

A+>/<.3=><3,?>398A3>237:<9@/.1/8/>3-+619<3>2738-98>38?9?=-+=>38190=>//6=

+-?6>C90

8138//<381+8.809<7+>398%-3/8-/=#+:/<=#+<>

2>>:=<9?9A/.?+?/3=:+:/<=

$/=/+<-2"8638/3=>2/9:/8+--/==38=>3>?>398+6</:9=3>9<C09<>2/'83@/<=3>C90(9669819819<0?<>2/<3809<7+>398

-98>+->>2/'"(3,<+<C</=/+<-2:?,=?9A/.?+?

&2/9:>373=+>39890>2/=/-98.+<C-996381A+>/<.3=><3,?>398A3>237:<9@/.&2/9:>373=+>39890>2/=/-98.+<C-996381A+>/<.3=><3,?>398A3>237:<9@/.

1/8/>3-+619<3>2738-98>38?9?=-+=>38190=>//6=1/8/>3-+619<3>2738-98>38?9?=-+=>38190=>//6=

,=><+->,=><+->

837:<9@/.1/8/>3-+619<3>273=:</=/8>/.09<>2/A+>/<-98=?7:>39890>2/=/-98.+<C-996381D98/

,+=/.98>2/2/+>><+8=0/<79./690>2/900638/,6997-+=>/<&23==>?.C3=>9-98><96>2//B3=>381-996381

=C=>/7=+8.>2/=>//6-+=>381:<+->3=/=389<./<>9:<9.?-/=>//6A3>2,/=>:9==3,6/;?+63>C&2/F>8/==

0?8->3989037:<9@/.1/8/>3-+619<3>273=09?8./.+--9<.381>9>2/7/>+66?<13-+6-<3>/<3+&23=+619<3>27

-9?:6/.A3>22/+>><+8=0/<79./6+8.7/>+66?<13-+6-<3>/<3++../..C8+73--9.3817/>29.+8.=/60

+.+:>3817?>+>39898>2/9<3138+61/8/>3-+619<3>27-+838-</+=/A+>/<.3=><3,?>398+.+:>3@/6C+8.

37:<9@/>2/:<9-/==/G-3/8-C&2/=37?6+>398</=?6>=90&,6997=29A>2+>>2/9:>373=/..3=><3,?>398

</.?-/.,C90A+>/<-98=?7:>398-97:+<381>9>2+>90,/09</9:>373=+>398&2/7+B37?7=?<0+-/

-996381<+>/+8.>2/<+>/90>/7:/<+>?</<3=/</.?-/.+8.>2//;?3+B/.<+>/38-</+=/=&2/0?8->3983=

,?36>09</B:6+38381>2/</6+>398=23:,/>A//8>2/-+=>381=://.+8.A+>/<.3=><3,?>398

/CA9<.=/CA9<.=

+619<3>271/8/>3-37:<9@/.=>//6=.3=><3,?>398-+=>381A+>/<-996381=/-98.+<C9:>373=+>398

-98>38?9?=

3=-3:638/=3=-3:638/=

8138//<381E%-3/8-/+8.&/-289691C%>?.3/=

#?,63-+>398/>+36=#?,63-+>398/>+36=

*2+3))3) +))+83+81*)&2/9:>373=+>39890>2/=/-98.+<C-996381A+>/<

.3=><3,?>398A3>237:<9@/.1/8/>3-+619<3>2738-98>38?9?=-+=>38190=>//6= +>/<3+6=$/=/+<-2

889@+>398=%%

&23=49?<8+6+<>3-6/3=+@+36+,6/+>$/=/+<-2"8638/2>>:=<9?9A/.?+?/3=:+:/<=

Statement of novelty

In this paper, an improved genetic algorithm is designed for the water consumption of the secondary

cooling zone based on the heat transfer model of the off-line bloom caster. This algorithm coupled

with heat transfer model and metallurgical criteria, added dynamic coding method and self-adapting

mutation on the original genetic algorithm, can increase the simulated water distribution adaptively,

improve the efficiency of the simulation process and the convergence ratio, and reduce the reheating

between the zones. In the experimental, it is found that the water consumption after optimization

reduced by 2%, compared to that of before optimization. The maximum surface cooling rate and the

rate of temperature rise reduced, and the equiaxed rate increases. Then a function is built for

explaining the relationship between casting speed and water distribution, which can be the direction

to control the cooling system in manufacturing process. So far, to our knowledge, although a lot of

intelligent algorithms are used to optimize the secondary cooling conditions, but there are few

reports on the simulation of this process with the developed algorithms. In this study, the improved

genetic algorithm to optimize the secondary cooling water distribution is concerned, and the results

show that the developed algorithm can save more water consumption with lower reheating and

cooling rates.

The optimization of the secondary cooling water distribution with improved

genetic algorithm in continuous casting of steels

Y.Y. Zhai

1

; Y. Li

*1

; B.Y. Ma; Z.Y. Jiang

2

1: School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China

2: School of Materials and Mechatronic Engineering, University of Wollongong, Wollongong 2500, Australia

*Corresponding Author: liying@mail.neu.edu.cn (Y. Li)

Abstract

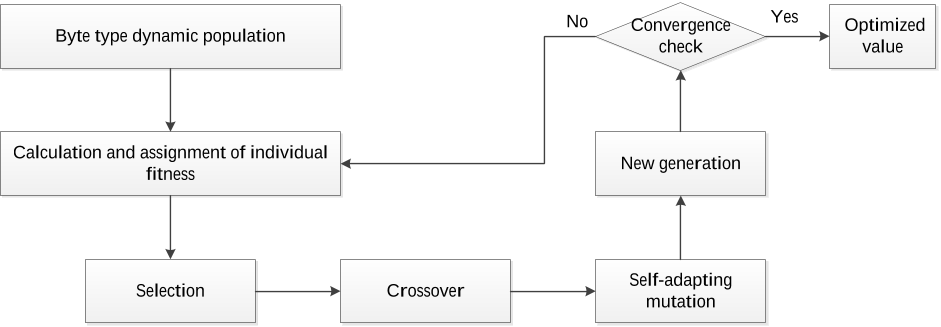

An improved genetic algorithm is presented for the water consumption of the secondary cooling

zone based on the heat transfer model of the off-line bloom caster. This study is to control the

existing cooling system and the steel casting practice in order to produce steel with best possible

quality. The fitness function of IGA (improved genetic algorithm) is founded according to the

metallurgical criteria. This algorithm coupled with heat transfer model and metallurgical criteria,

added dynamic coding method and self-adapting mutation on the original genetic algorithm, can

increase water distribution adaptively and improve the process efficiency. The simulation results of

T91 bloom show that the optimized distribution reduced by 2% of water consumption comparing to

that of before optimization. The maximum surface cooling rate and the rate of temperature rise

reduced, and the equiaxed rate increases. The function is built for explaining the relationship

between the casting speed and water distribution.

Keywords: Continuous casting, Secondary cooling, Water distribution, Genetic algorithm,

Self-adapting mutation

Introduction

Continuous casting technology, a main method in steelmaking industry, has been rapidly

developed in recent years. In this process, liquid steel from tundish is poured into mold to form

billets, blooms or slabs. Since the cooling conditions at the mold and air cooling zone are relatively

stable for a given caster, with only the secondary cooling zone (SCZ) capable of being adjusted

within a wide range, the quality and output of casting is closely related to the SCZ. Given that the

cooling process removes the superheat and the latent heat of fusion at the solidification front, the

main cause of internal crack, surface crack and center segregation is the unreasonable secondary

cooling structure. These defects should be avoided for the sake of competitiveness in manufacturing.

Thus, it is critical to control and optimize the secondary cooling in the whole casting process. It is

not feasible to conduct a lot of experimental trials to calculate the influence of different operational

parameters due to economic reasons. Mathematical models and optimization algorithms are useful

tools for the optimization of water distribution in the SCZ. The heat transfer model is the foundation

of the optimization of the SCZ. This model is an initial boundary problem of partial differential

equation (PDE). It cannot be solved using analytical method and also the computational time

solution is too long. In the secondary cooling process, the value function of metallurgical criterion is

complicated, and the efficiency of general optimization method is low.

The traditional method for solving the optimization problem of the secondary cooling process is

complex nonlinear optimization problem with poor efficiency. Intelligent optimization algorithm

has been rapidly developed in secondary cooling water distribution, which is an important factor

affecting the quality of the bloom. The improper distribution of water will make surface cracks, the

crack in the middle, the center of the crack, the crack corner, bulging and so on. They will seriously

affect the production and product quality finishing process. A number of intelligent optimization

methods used in the secondary cooling process have been developed rapidly. Lally et al. used an

optimization method with heat flow and solidification model to determine the parameters that

maximize the quality of final product of billet and slab casters [1-2]. Santos et al. developed an

intelligent optimization method of genetic algorithm (GA) with finite difference heat transfer model

based on the metallurgical criterion and maximum withdraw speed to control the secondary cooling

zone of slab continuous casting, and heuristic search algorithms were used to minimize the

consumption water and the smooth temperature gradient in the secondary cooling process [3-5]. A

model optimization of billet continuous casting steel secondary cooling with an implicit enthalpy

mathematical solidification was developed to calculate three dimensional and stationary temperature

fields and to decrease center segregation [6]. An approach based on Hamilton-Jacobi-Bellman

equation satisfying the value function has been used to the optimal problem of the SCZ with water

spray control of a low-carbon billet caster [7]. Chakraborti et al. solved the pertinent transport

equations in the mold of continuous caster using a finite volume approach with genetic algorithms.

The results showed significant improvements of the casting velocity and the solidified shell

thickness [8]. Meng et al. proposed an enhanced particle swarm optimization algorithm to optimize

the secondary cooling of billet, which has been reported with good convergence rate and

convergence precision [9].

This study presents an optimization model for controlling the water intensities of the water in the

SCZ of bloom caster. Considering the simulation condition, a heat transfer model of bloom caster is

applied using an analytical solution for the temperature profile. Then an improved genetic algorithm,

which contains byte type dynamic coding method and self-adapting mutation, is used to code the

secondary cooling water distribution. The procedure corresponds to the fitness function determined

by highly conflicting technological and metallurgical requirements. These methods increase the

distribution adaptability and improved the efficiency, comparing with the traditional optimization

methods of solving multi-objective optimization and other non-linear problems. In the present study,

the secondary cooling water distributions are optimized in different casting speeds, and then the

function of second cooling optimal water distribution and casting speed is obtained. This model

improved the equiaxed rate of the bloom and reduced the maximum surface cooling rate and the rate

of temperature rise. As a result, the optimized bloom has better quality.

The Mathematical Optimization Model

The state system used in the present study is a two-dimensional heat transfer model in which the

heat conduction to the withdrawal direction is neglected. It is because that the withdrawal rate of

steel is relatively high and the thermal conductivity is low. The heat transfer model is developed and

applied to calculate the temperature distribution and solid shell thickness profile of bloom

continuous casting. It is the foundation of the optimization of secondary cooling zone. The

optimization module of the water distribution of secondary cooling zone using Genetic Algorithm is

established according to the metallurgical criteria for bloom and target temperature controlling

principle.

Suppose that the cross section of the bloom is a rectangular, Ω=[0, a]×[0, b], which is moving

along the z direction with a constant speed. Let T(x, y, t) be the temperature at the point (x, y, t).

Then T satisfies the following nonlinear heat conduction equation with boundary conditions [10].