WANG,H.,MURZYN,F.,andCHANSON,H.(2014)."TotalPressureFluctuationsandTwo‐PhaseFlowTurbulenceinHydraulicJumps."

ExperimentsinFluids,Vol.55,No.11,Paper1847,16pages(DOI:10.1007/s00348‐014‐1847‐9)(ISSN0723‐4864).

1

Total pressure fluctuations and two-phase flow turbulence in hydraulic

jumps

Hang Wang (

1

) (*), Frédéric Murzyn (

2

) and Hubert Chanson (

1

)

(

1

) The University of Queensland, School of Civil Engineering, Brisbane QLD 4072, Australia

(

2

) ESTACA Campus Ouest, Parc Universitaire de Laval Changé, BP 53061 Laval Cedex 9, France

(*) Corresponding author: hang.wang@uqconnect.edu.au

Abstract

The large-scale turbulence and high air content in a hydraulic jump restrict the application of many

traditional flow measurement techniques. This paper presents a physical modelling of hydraulic jump,

where the total pressure and air-water flow properties were measured simultaneously with intrusive

probes in the jump roller, namely a miniature pressure transducer and a dual-tip phase detection

probe. The total pressure data were compared to theoretical values calculated based upon void

fraction, water depth and flow velocity measured by the phase-detection probe. The successful

comparison showed valid pressure measurement results in the turbulent shear region with constant

flow direction. The roller region was characterised by hydrostatic pressure distributions, taking into

account the void fraction distributions. The total pressure fluctuations were related to both velocity

fluctuations in the air-water flow and free-surface dynamic above the roller, though the time scales of

these motions deferred substantially.

Keywords

Hydraulic jump, Total pressure, Two-phase flow, Turbulence, Physical modelling

List of symbols

C Time-averaged void fraction

C

max

Local maximum time-averaged void fraction in the shear flow region

D

#

Dimensionless diffusivity in the turbulent shear region

D* Dimensionless diffusivity in the free-surface region

d

1

Inflow water depth immediately upstream of the jump toe [m]

F Bubble count rate [Hz]

F

clu

Longitudinal bubble cluster count rate [Hz]

(F

clu

)

max

Maximum cluster count rate in the shear flow region [Hz]

F

fs

Characteristic free-surface fluctuation frequency [Hz]

F

max

Maximum bubble count rate in the shear flow region [Hz]

F

p

(H)

Upper total pressure fluctuation frequency [Hz]

F

p

(L)

Lower total pressure fluctuation frequency [Hz]

Fr

1

Inflow Froude number,

11 1

Fr = V g×d

g Gravity acceleration [m/s

2

]

h Upstream gate opening [m]

L

r

Length of jump roller [m]

P Time-averaged total pressure [Pa]

P

k

Kinetic pressure [Pa]

P

max

Maximum mean total pressure in the shear flow region [Pa]

P

o

Piezometric pressure [Pa]

p' Standard deviation of total pressure [Pa]

p'

max

Maximum total pressure fluctuation [Pa]

Q Flow rate [m

3

/s]

WANG,H.,MURZYN,F.,andCHANSON,H.(2014)."TotalPressureFluctuationsandTwo‐PhaseFlowTurbulenceinHydraulicJumps."

ExperimentsinFluids,Vol.55,No.11,Paper1847,16pages(DOI:10.1007/s00348‐014‐1847‐9)(ISSN0723‐4864).

2

Re

Reynolds number,

11

Re =ρ×V ×d μ

T Time lag for maximum cross-correlation coefficient [s]

T

0.5

Time lag for maximum auto-correlation coefficient [s]

Tu Turbulence intensity

Tu" Decomposed turbulence intensity of high-frequency signal component

U Free-stream velocity in upstream supercritical flow [m/s]

V Average air-water interfacial velocity [m/s]

V

max

Maximum interfacial velocity in the shear flow region [m/s]

V

recirc

Average recirculation velocity in the free-surface region [m/s]

V

1

Average inflow velocity [m/s]

v' Standard deviation of interfacial velocity [m/s]

W Channel width [m]

x Longitudinal distance from the upstream gate [m]

x

1

Longitudinal position of jump toe [m]

Y

Cmax

Characteristic elevation of local maximum void fraction in the shear region [m]

Y

Fmax

Characteristic elevation of maximum bubble count rate in the shear region [m]

Y

Pmax

Characteristic elevation of maximum mean total pressure in the shear region [m]

Y

p'max

Characteristic elevation of maximum total pressure fluctuation in the shear region

[m]

Y

Vmax

Characteristic elevation of maximum interfacial velocity in the shear region [m]

Y

0.5

Characteristic elevation of half maximum interfacial velocity [m]

Y

50

Characteristic elevation where C = 0.5 [m]

Y

90

Characteristic elevation where C = 0.9 [m]

y Vertical distance from the channel bed [m]

y* Characteristic elevation of local minimum void fraction [m]

z Transverse distance from the channel centreline [m]

Δx Longitudinal separation distance between two phase-detection probe sensors [m]

δ Inflow boundary layer thickness at channel bed [m]

μ Water dynamic viscosity [Pa×s]

ρ

Water density [kg/m

3

]

τ Time lag [s]

τ

0.5

Time lag between maximum and half maximum cross-correlation coefficient [s]

1 Introduction

A hydraulic jump is a rapidly-varied open channel flow characterised by a sudden transition from a

supercritical flow motion to a subcritical regime. The jump toe, where the upstream flow impinges

into the downstream region, is a singular locus with discontinuity in velocity and pressure fields

(Rajaratnam 1967). The transition region immediately downstream of the toe is named the jump

roller because of the presence of large-scale vortices and flow recirculation. The jump roller is a

turbulent two-phase flow region with coexistence of and interaction between air entrainment,

turbulence and flow instabilities.

The turbulent nature of hydraulic jump leads to an efficient energy dissipation rate. For example, an

inflow Froude number Fr

1

= 9 gives a theoretical energy dissipation rate exceeding 70%, where the

Froude number is defined as Fr

1

= V

1

×(g×d

1

)

-1/2

, V

1

being the average inflow velocity and d

1

the

inflow depth. Therefore hydraulic jumps are often generated in hydraulic structures for the purpose

WANG,H.,MURZYN,F.,andCHANSON,H.(2014)."TotalPressureFluctuationsandTwo‐PhaseFlowTurbulenceinHydraulicJumps."

ExperimentsinFluids,Vol.55,No.11,Paper1847,16pages(DOI:10.1007/s00348‐014‐1847‐9)(ISSN0723‐4864).

3

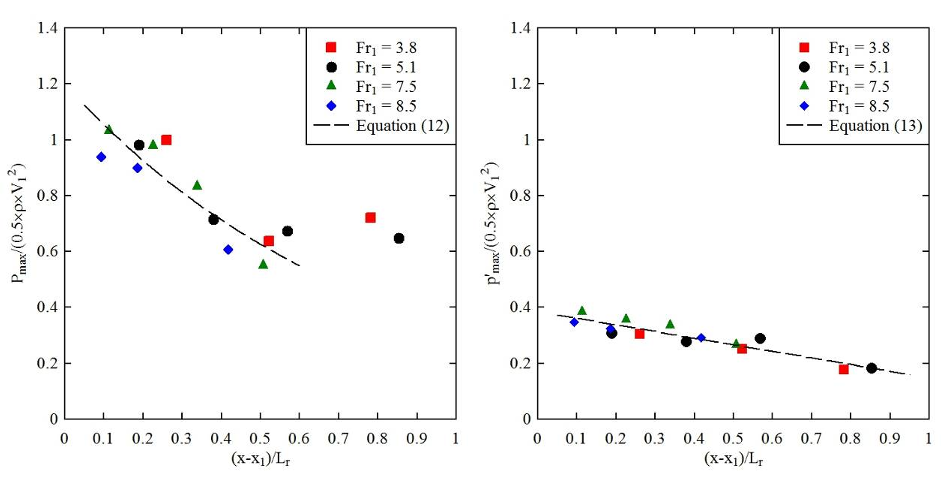

of energy dissipation (Fig 1). However, the large shear force and fluctuating motions of the flow may

challenge the strength of construction, e.g., on the bottom of the jump in a stilling basin. In the early

20

th

century, the attention to hydraulic jump was first triggered with the design of energy dissipators,

which was developed by USBR (U.S. Bureau of Reclamation) in 1940s and 1950s (Riegel and Beebe

1917, Peterka 1958). A number of studies contributed to the pressure quantification mainly beneath

hydraulic jumps (Vasiliev & Bukreyev 1967, Schiebe 1971, Abdul Khader & Elango 1974, Lopardo

& Henning 1985, Fiorotto & Rinaldo 1992, Yan & Zhou 2006, Lopardo & Romagnoli 2009). The

relationship between cavitation occurrence and pressure fluctuations was investigated (Narayanan

1980). The pressure fluctuations were further correlated with water level fluctuations and/or velocity

turbulence in some limited flow conditions with minor aeration (Onitsuka et al. 2009, Lopardo 2013).

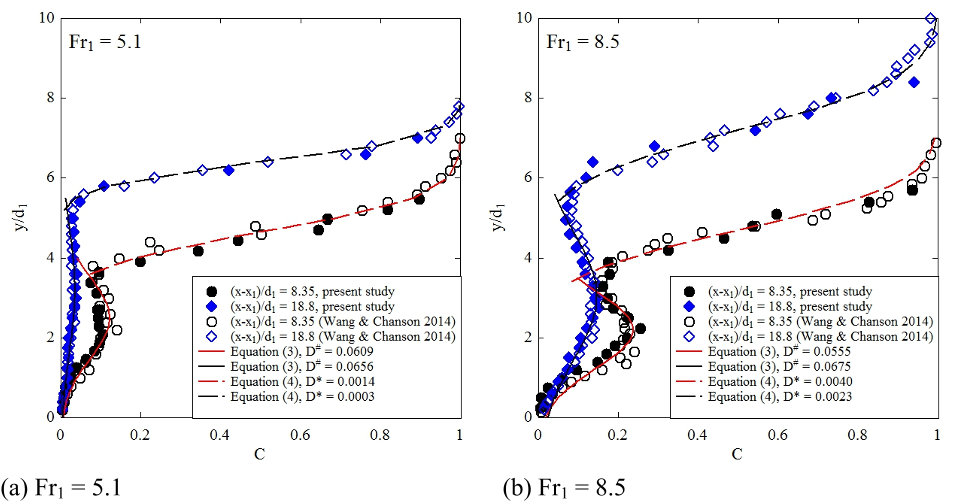

In most prototype conditions with large inflow Froude number, the air entrainment in hydraulic jump

is significant. Air entrapped at the jump toe as well as through the rough roller surface is advected

downstream by large vortical structures (Long et al. 1991). The diffusive advection of air bubbles

interplays with the turbulence development. The studies of two-phase flow properties were

represented by Rajaratnam (1962), Resch & Leutheusser (1972) and Chanson (1995) describing the

air concentration and interfacial velocity characteristics using air-water interface detection

techniques. The turbulence characterisation was promoted by Chanson & Toombes (2002) and

Chanson & Carosi (2007) and recently developed by Wang et al. (2014) based upon statistical

analysis of interface detection signals. In a few attempts of numerical modelling, the air entrainment

was rarely taken into account together with the dynamic features of the flow (Richard & Gavrilyuk

2013). Physical modelling with consideration of simultaneous air entrainment and flow

turbulence/fluctuations included Cox & Shin (2003), Murzyn & Chanson (2009) and Wang &

Chanson (2014).

Direct pressure measurement in hydraulic jump flows with strong air entrainment are lacking despite

the significance in hydraulic engineering. This paper presents new experiments measuring the total

pressure distributions within the jump roller. The air-water flow properties were characterised at the

adjacent locations, and the water level fluctuations above were recorded as well. The application of

total pressure transducer in such turbulent bubbly flow was justified by a comparison between the

total pressure output and calculations based upon air-water flow measurement results. The present

work provides new information on the flow regime and fluctuating nature of hydraulic jumps, and

allows further investigation on the interactions between turbulence, aeration and flow instabilities in

such a flow.

2 Physical modelling and instrumentation

2.1 Dimensional considerations

Any theoretical and numerical analyses of hydraulic jumps are based upon a large number of

relevant equations to describe the two-phase turbulent flow motion and the interaction between

entrained air and turbulence. The outputs must be tested against a broad range of gas-liquid flow

measurements:"Unequivocally [...] no experimental data means no validation" (Roache 2009).

Physical modelling requires the selection of a suitable dynamic similarity (Liggett 1994).

Considering a hydraulic jump in a smooth horizontal rectangular channel, dimensional

considerations give a series of dimensionless relationships in terms of the turbulent two-phase flow

properties at a position (x,y,z) within the hydraulic jump roller as functions of the inflow properties,

fluid properties and channel configurations. Using the upstream flow depth d

1

as the characteristic

length scale, a dimensional analysis yields

WANG,H.,MURZYN,F.,andCHANSON,H.(2014)."TotalPressureFluctuationsandTwo‐PhaseFlowTurbulenceinHydraulicJumps."

ExperimentsinFluids,Vol.55,No.11,Paper1847,16pages(DOI:10.1007/s00348‐014‐1847‐9)(ISSN0723‐4864).

4

11 11

1

22

11111 111111

F×d x-x v ' x

Pp'Vv' yz W

, , , ,C, ,... = F , , ,Fr ,Re, , , ,...

0.5×ρ×V 0.5×ρ×V V V V d d d V d d

(1)

where P and V are the total pressure and velocity respectively, p' and v' are pressure and velocity

fluctuations, C is the void fraction, F is the bubble count rate, x

1

is the jump toe position, Re is the

Reynolds number, W is the channel width and the subscript 1 refers to the inflow conditions. In a

hydraulic jump, the momentum considerations demonstrated the significance of the inflow Froude

number, and the selection of the Froude similitude derives implicitly from basic theoretical

considerations (Lighthill 1978, Liggett 1994). Equation (1) shows that measurements in small size

models might be affected by viscous scale effects because the Reynolds number is grossly

underestimated. In the present study, the experiments were performed in a relatively large-size

facility to minimise scale effects (Murzyn & Chanson 2008, Chanson & Chachereau 2013).

2.2 Experimental setup and flow conditions

The experimental channel was 3.2 m long and 0.5 m wide, built with horizontal HDPE bed and 0.4 m

high glass sidewalls (Fig 1b). The inflow was supplied to the flume from a constant head tank. A

rounded undershoot gate of the head tank induced a horizontal impinging flow without contraction.

The gate opening was set at h = 0.02 m, and hydraulic jumps were generated at x

1

= 0.83 m

downstream of the gate. The inflow depth was measured using a point gauge right upstream of the

jump toe. The tailwater depth and jump toe position were controlled by an overshoot gate at the end

of the channel. The flow rate was measured with a Venturi meter in the supply line. While the flow

rate measurement was within an accuracy of 2%, the precision of the determination of inflow depth

and jump toe position relied largely on the fluctuation level of the flow.

Four inflow Froude numbers Fr

1

= 3.8, 5.1, 7.5 and 8.5 were tested, corresponding to Reynolds

numbers 3.5×10

4

< Re < 8.0×10

4

. The total pressure and two-phase flow properties were measured

locally with intrusive total pressure probe and phase-detection probe. The probes were placed side by

side with a 9 mm transverse distance between the sensor tips and sampled at a number of elevations

in a vertical cross-section on the channel centreline. The instantaneous water elevation above the

measurement location was measured non-intrusively with an acoustic displacement meter. The

instrumental setup is illustrated in Figure 2, and the flow conditions are summarised in Table 1 along

with the longitudinal positions of the scanned cross-sections. With an inflow length x

1

/h = 41.5, the

inflow conditions were characterised by partially-developed boundary layer at the channel bed (δ/d

1

< 1 at x = x

1

, Table 1, 7

th

column). Figure 3a presents typical inflow velocity profiles measured with

a Prandtl-Pitot tube along the channel centreline. A developing boundary layer was shown with a

constant free-stream velocity U. Figure 3b compares the free-stream velocity U with the average

inflow velocity V

1

for a broader range of flow conditions. The results indicated U ≈ 1.1×V

1

because

the velocities in boundary layers were lower than the cross-sectional average. Resch & Leutheusser

(1972) and Thandaveswara (1974) compared the air-water flow properties for different types of

inflow conditions (partially-developed, fully-developed and per-entrained). The presence of highly-

aerated shear flow region (see 3.2.1 below) was only observed for partially-developed inflow

conditions, with the shortest aeration length (Chanson 1997).

2.3 Instrumentation

The total pressure probe consisted of a silicon diaphragm sensor mounted on the probe tip. The

sensor was a miniature Micro-Electro-Mechanical-System technology based pressure transducer

(Model MRV21, by MeasureX, Australia). Such a diaphragm pressure sensor is not affected by the

WANG,H.,MURZYN,F.,andCHANSON,H.(2014)."TotalPressureFluctuationsandTwo‐PhaseFlowTurbulenceinHydraulicJumps."

ExperimentsinFluids,Vol.55,No.11,Paper1847,16pages(DOI:10.1007/s00348‐014‐1847‐9)(ISSN0723‐4864).

5

presence of bubbles and does not require to be purged. The sensor had a 5 mm outer diameter with 4

mm diameter sensor. The model provided a measurement range between 0 and 1.5 bars (absolute

pressures). The response frequency was in excess of 100 kHz. The sampling frequency was set at 5

kHz in the present study, though the signal was filtered by a signal amplification system to eliminate

noises above 2 kHz. A daily calibration was conducted and regularly checked, because the output

voltage appeared to be temperature and ambient-pressure sensitive. The largest uncertainty of the

total pressure measurements was thought to be introduced by the fluctuations in atmospheric

pressure reading.

The dual-tip phase-detection probe was designed to pierce bubbles and droplets with its two needle

sensors and worked based upon the difference in electrical resistance between air and water. The

needle sensor tips (0.25 mm inner diameter) were separated longitudinally by Δx = 7.25 mm. While

the signal of each sensor gave the local void fraction and bubble count rate data, a cross-correlation

between the signals provided an average time T of the air-water interfaces travelling over the

distance Δx, yielding a mean longitudinal interfacial velocity V = Δx/T. The phase-detection probe

was excited by an electronic system designed with a response time less than 10 µs, and scanned at 5

kHz simultaneously with the total pressure probe and an acoustic displacement meter above the

probe leading tip. A Microsonic

TM

Mic+25/IU/TC acoustic displacement meter measured the

instantaneous water elevation with a 50 Hz response frequency which was lower than the sampling

rate. The sensor height was carefully adjusted to ensure that the displacement meter measurement

range covered the maximum free-surface fluctuations, and the erroneous samples caused by

splashing droplets were removed from the signal.

The simultaneous sampling of all instruments was performed for 180 s at each measurement location.

3 Results

3.1 Basic flow patterns

Observations showed some enhanced flow aeration and turbulent fluctuations with increasing Froude

number. The large-scale turbulent structures inside the roller were visualised by the entrained air

bubbles (Fig 1b). The formation of large turbulent structures was linked to the oscillations of jump

toe position and free-surface fluctuations (Long et al. 1991, Wang & Chanson 2014, Wang et al.

2014). These motions were observed in a pseudo-periodic manner, together with the associated air

entrapment and macroscopic variation in velocity and pressure fields. For instance, the slow pressure

pulsations could be felt by placing a hand in the roller. Basically the pulse of increasing impinging

pressure appeared to correspond to the downstream ejection of large vortices.

The water elevation measured along the channel centreline outlined the time-averaged free-surface

profiles similar to the visual observations. The length of hydraulic jump roller L

r

is defined as the

longitudinal distance over which the water elevation increases monotonically. The roller length was

derived from the free-surface profile and found to be an increasing function of the Froude number. A

linear relationship was given by the dataset consisting of Murzyn et al. (2007), Kucukali & Chanson

(2008), Murzyn & Chanson (2009), Wang & Chanson (2014) and the present study:

r

1

1

L

= 6×(Fr -1)

d

for 2 < Fr

1

< 10 (2)