Q2. What future works have the authors mentioned in the paper "Toughness of natural rubber compounds under biaxial loading" ?

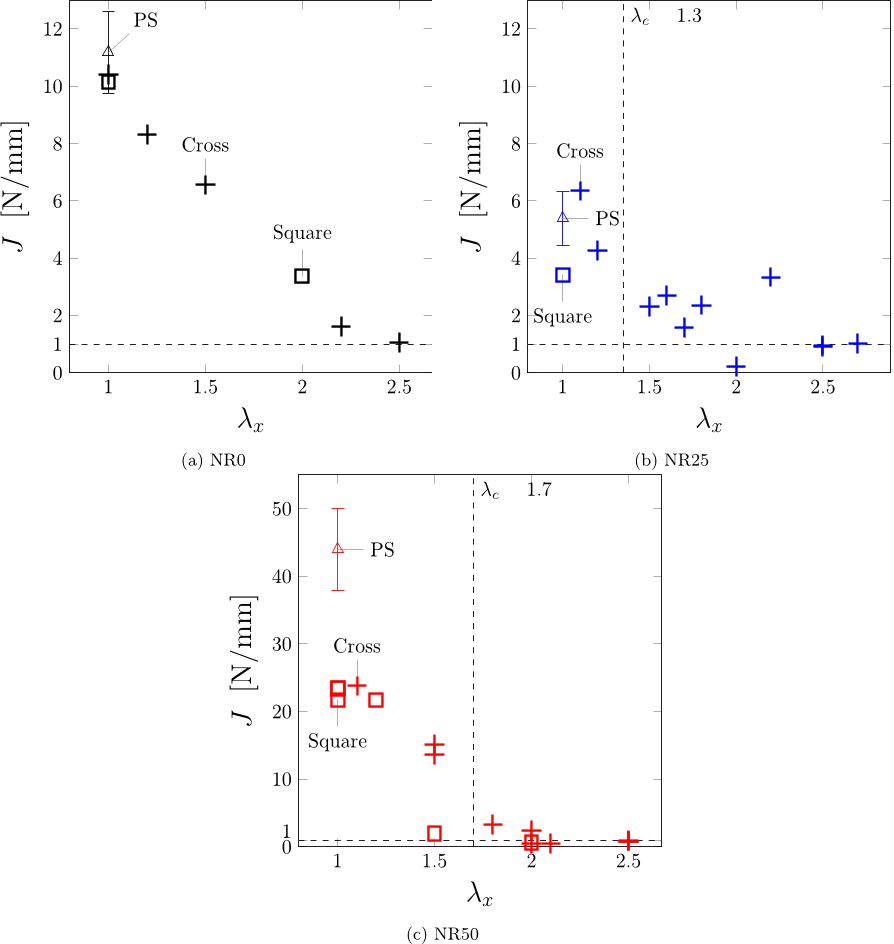

In this work previous results relevant to fracture tests under biaxial loading conditions were analysed anew in the framework of non-linear elastic fracture mechanics, and paired with some new results on a different test set-up, to study how the strain induced strength anisotropy influences toughness.

Q3. What is the main reason why rubbers are hard?

It is well known that crystallising rubbers develop a strong strength anisotropy upon stretching: broadly speaking, if stretched along some direction they can become easier to break upon subsequent stretching perpendicularly to this direction [1–3].

Q4. What was the effect of stretching on the rubber?

Gent and Kim [2] tested notched rubber strips that were stretched, before testing, in a direction perpendicular to the testing one; their grip system allowed them to keep the pre-stretching level fixed during testing.

Q5. What is the effect of the cuts on the material behaviour?

Nevertheless it is to be noted these cuts acts as stress raiser, reducing the range of strains for which the biaxial material behaviour can be measured, as they cause premature failure at the edges.

Q6. What was the power law used to describe the shape of the cracks?

Although in brittle materials branches tend to partially follow the main crack path (they grow “forward”) it was here assumed that a power law could be used as a very rough approximation to describe their shape in order to introduce them into a finite element model.

Q7. What is the strain energy density of the crack tip?

When there are no sideways cracks, the strain energy density is singular and approaches the tip following a 1/x power law, as indicated by the corresponding dashed line.

Q8. What is the reason for the weak planes?

The very same phenomenon that has been conjectured to be source of sideways crack propagation [4], i.e. the development of weak planes due to the orientation and crystallisation of rubber molecules, may as well be cause of the strong toughness decrease with applied pre-stretch.

Q9. What is the effect of sideways cracks on the material resistance?

In this sense the development of the sideways cracks completely shields the crack tip, strongly reducing the stress intensity near the original crack tip and providing a huge improvement in the apparent material resistance to crack propagation.

Q10. How was the vanishing of the J-integral verified?

The vanishing of the J-integral was also verified by the compliance method [30], i.e. by extending the main crack tip along the x direction at fixed boundary displacement and studying the variation of the total strain energy U as a function of the crack length a.

Q11. What was the difference between the two tests?

For both the tests the simulations were run for a time corresponding to the fracture time, defined as the initiation of propagation of the main in crack in the direction parallel to the initial notch, as determined from the video-recordings.