7

Use of Fungi in Pulping Wood:

An Overview of Biopulping Research

T. Kent Kirk, Richard R. Burgess, and

John W. Koning, Jr.

Introduction

Fresh wood chips destined and stored for pulp production are rapidly colonized

by a variety of microorganisms, including many species of fungi. These organisms

compete vigorously while easily assimilable foodstuffs last, and then their popula-

tions decrease. They are replaced by fungi that are able to degrade and gain

nourishment from the cell wall structural polymers: cellulose, hemicelluloses,

and lignin. Left unchecked, these last colonizers. mostly “white-rot fungi ,"

eventually decompose the wood to carbon dioxide and water. Some of them

selectively degrade the lignin component, which is what chemical pulping pro-

cesses accomplish. Biopulping is the concept of deliberately harnessing white-

rot fungi for pulping.

Pulp is produced from wood by either chemical delignification, mechanical

separation of the cells (fibers), or combinations of chemical and mechanical

methods. Mechanical pulping methods are used increasingly because they give

much higher yields (80% to 90% based on the wood) than chemcial methods

(40% to 50% yields). They also are less polluting than chemical methods. and

mills using these methods are much less expensive to buiId. Currently, about

25% of world pulp production is by mechanical means. The main disadvantages

of mechanical pulping methods are the production of lower quality pulps, which

are unsuitable for fiber products that need high strength properties, and the amount

of energy required for production (and consequent cost).

Chemical pretreatment of wood chips are used to enhance the strength proper-

ties of mechanical pulps. Making such chemimechanical pulps, however, gener-

ates chemical waste streams that mush be treated, and it lowers the pulp yield by

removing wood substance (mainly hemicelluloses and lignin). Biopulping as

studied to date is actually “biomechanical” pulping, the use of fungi to replace

chemicals in pretreating wood for mechanical pulping.

99

100 / Kirk, Burgess, and Koning

Past Work on Biopulping

Early chemical analyses of wood partly decayed by certain white-rot fungi re-

vealed that lignin had often been removed selectively; that is, the cellulose

content had increased. Actually, some naturally white-rotted woods are so heavily

delignified that they resemble chemical pulps and can be made into paper with

excellent properties. Thus, the concept of biopulping was probably obvious to

early investigators.

Perhaps the first serious consideration of fungal delignification for pulping was

by researchers at the West Virginia Pulp and Paper Company (now Westvaco

Corporation) research laboratory in the United States in the 1950s. Their investiga-

tion resulted in a published article (Lawson and Still, 1957) that surveyed 72

lignin-degrading fungi and summarized what was known about how the fungi

degrade lignin. At that time, very little was known. At about the same time, a

study of the effect of natural decay of pine by white-rot fungi on chemical pulping

showed that most paper strength properties increased as the extent of decay

increased (Reis and Libby, 1960: Kawase, 1962).

Any research on biopulping per se that might have been done by various

companies from the 1950s to the present has not been published. Also unpub-

lished, except as an internal report at the Forest Products Laboratory, was a 1972

study of “biomechanical” pulping by T. K. Kirk and Prof. Knut P. Kringstad,

then at North Carolina State University in Raleigh (USA). Aspen wood chips

were partly decayed by

Rigidoporus ulmarius

(Sow.:

Fr. ) Imaz. and mechanically

fiberized to a pulp, and the pulp was made into paper. Pulping these chips required

fewer revolutions in the pulping apparatus than did the pulping of untreated

control wood, suggesting lowered energy consumption; also, the paper from the

biomechanical pulp was stronger.

Similar work was done shortly thereafter at the Swedish Forest Products

Laboratory (STFI) in Stockholm, and the first published paper on biopulping per

se (Ander and Eriksson, 1975) described results very similar to those of Kirk and

Kringstad. In 1976, the Swedish researchers patented a “method for producing

cellulose pulp” (Eriksson et al.,

1976). After the initial study, this group worked

on various aspects of biopulping, primarily with the white-rot fungus

Sporotri-

chum pulverulentum

Novobranova. Mean while, our work at the Forest Products

Laboratory of the USDA Forest Service in Madison focused on the mechanism

of lignin degradation by a white-rot fungus that was tentatively referred to as

Peniophora “G .“

Both fungi were chosen because they grew and degraded lignin

quite rapidly in comparison to other fungi; they also produced copious conidia

and thus were easy to manipulate. It was a surprise to both laboratories when

the two fungi were found to be synonymous, and they are now classified as

Phanerochaete chrysosporium Burds. (Burdsall and Eslyn. 1974).

The Swedish researchers made a number of contributions to biopulping (review:

Eriksson and Kirk, 1985). They described the growth rates of

P. chrysosporium

Use

of

Fungi in Pulping Wood / 101

through wood, finding that colonization of pulpwood chips is unlikely to be rate-

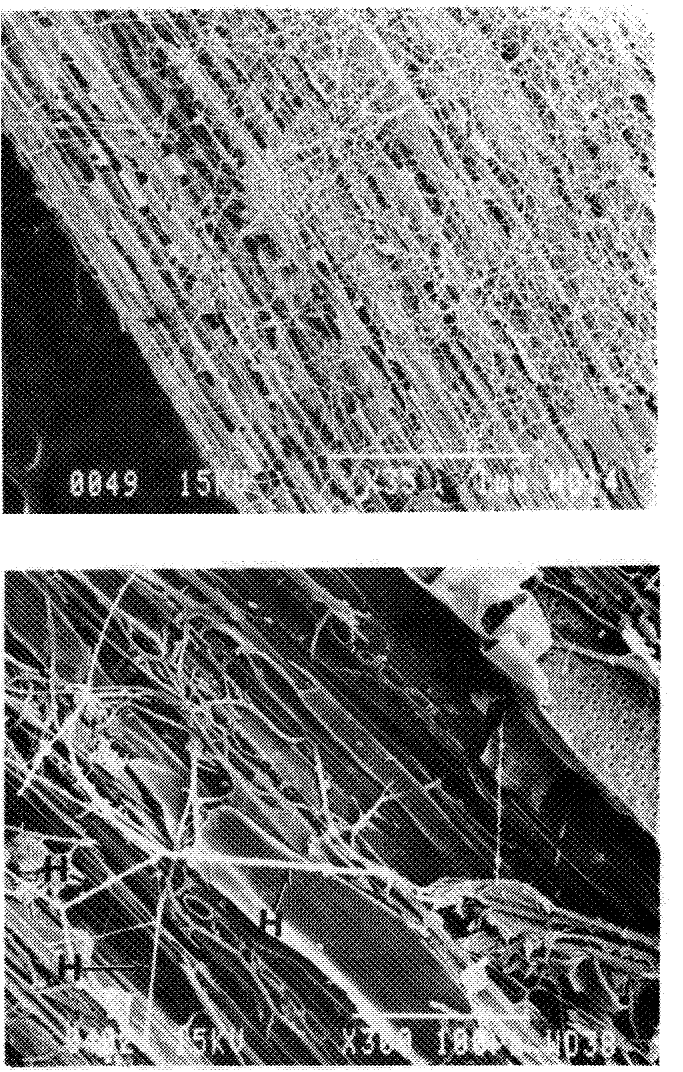

determining. Scanning and transmission electron microscopy were used to show

the growth patterns in wood and the degradation patterns of the cell walls. The

group conducted studies on biomechanical pulping, showing energy savings

and paper strength improvements. A considerable effort went into developing

cellulase-less mutants of selected white-rot fungi for biopulping (Johnsrud and

Eriksson, 1985). Attempts by the group to scale up the biopulping process were

not notably successful (Samuelsson et al.,

1980). That work, however, was

undoubtedly premature because insufficient information was available on how to

scale up the fungal treatment. Subsequent work on a large scale with bagasse,

done in cooperation with Cuban scientists, gave more promising results (Johnsrud

et al., 1987).

Biopulping received little attention outside of Sweden until our recent investiga-

tions. In one small study, Bar-Lev et al. (1982) reported that treatment of a coarse

mechanical pulp with

P. chrysosporium

decreased the energy required for further

fiberization and increased paper strength properties. Akamatsu et al. (1984) found

that treatment of wood chips with any of 10 white-rot fungi decreased mechanical

pulping energy; with three of the fungi (Trametes sanguinea, T. coccinea, and

Coriolus hirsutus), treatment increased paper strength.

Biopulping Consortium Research

Taken together, the results of these various studies suggested to us in 1986 that

biomechanical pulping merited a comprehensive investigation. Consequently, in

April 1987 a cooperative research program on biopulping was established. involv-

ing the Forest Products Laboratory, the University of Wisconsin Biotechnology

Center, and nine pulp and paper and related companies. The number of companies

in Biopulping Consortium had grown to 20 by April 1990. The overall objective

of the 5-year consortium research effort is to evaluate the scientific and technical

feasibility of using a fungal pretreatment with mechanical pulping to save energy

and/or improve pulp and paper properties. In addition. we have assumed that the

fungal pretreatment will have less environmental impact than have chemical

pretreatment, a significant factor in its own right.

The Biopulping Consortium research group is divided into six closely coordi-

nated teams. The fungal research team screens species and strains of white-rot

fungi from culture collections, as well as new isolates. Screening is based on

growth and wood decay rates and on selectivity for lignin degradation in wood.

The team also works to optimize the fungal pretreatment and, importantly,

produces fungal-treated chips for evaluation by the pulp and paper research team.

The pulp and paper team determines energy consumption required for pulp

production and measures pulp and paper properties. The enzyme team seeks

to determine which of the extracellular enzymes secreted during the fungal

102 / Kirk, Burgess, and Koning

pretreatment are beneficial for pulping and which are not beneficial. Emphasis is

on the components of the lignin- and cellulose-degrading systems. The molecular

genetics team has focused on P.

chrysosporium

and ultimately seeks to engineer

improved strains for biopulping. Lignin- and cellulase-degrading systems again

are the focus. An engineering and scale-up team is looking at the fungal pretreat-

ment as an engineered solid substrate fermentation. and it is working with the

fungal research team to determine critical parameters. Supporting the other teams

is an information group. Using sophisticated computer search strategies, the

information team screens the scientific literature and specializes in retrieving

information from particular sources, such as Japanese patent applications.

The industrial partners partially fund the project and provide input during

semiannual meetings with the researchers. The industrial partners are provided

with both research results and synopses of the expanding world literature of

biotechnology as it affects or might affect the pulp and paper industry. Participa-

tion in the consortium also provides the industrial partners with ready personal

access to biotechnology researchers (most of the companies do not have them in

house) and acquaintance with students, postdoctoral associates, and technicians,

who constitute a potential employee pool.

The consortium has made good research progress. Some of the key published

findings are summarized in the following paragraphs. Details are given in the

cited papers.

Research was initiated by screening species and strains of white-rot fungi for

selective removal of lignin from wood blocks (Otjen et al., 1987: Blanchette et

al., 1988). Wide variation was found among species and among strains within

certain species. For example. in 12 weeks Peniophora hydnoides (Cke. and

Mass. ) M.P. Chris. [

=Phanerochaete rimosa (Cke. ) Burds. ] removed 26% of

the lignin and 24% of the glucan (cellulose) from birch wood. whereas

P.

chrysosporium

Burds. (strain BKM F-1767) was highly selective and removed

73% of the lignin and only 15% of the glucan. Similarly, in 12 weeks,

Heterobasi-

dion annosum

(Fr. ) Bref. removed nearly equal proportions of lignin and glucan

(26% and 23%) from pine, whereas

Ceriporiopsis subvermispora

(Pil. ) Gilbn. et

Ryv. removed 50% and 3% of lignin and glucan, respectively. Within the species

P. chrysosporium, strain HHB-11741 removed 51% and 48% of the lignin and

glucan from birch wood, wherease strain BKM F-1767, as noted, removed 73%

and 15% of lignin and glucan. respectively, pointing to substantial intraspecies

variation. Based on these initial screenings. several species-and in some cases,

specific strains—were chosen for biopulping studies. Screening continues. how-

ever, and some interesting new fungi have recently been selected for further

study. A total of over 200 strains have been screened. Although selective removal

of lignin does not correlate strictly with efficacy of biopulping pretreatment, the

fungi selected by this method have proved to be effective for biopulping.

Better screening methods are needed. A somewhat faster method for screening

for selective lignin removal was described recently by Nishida et al. ( 1988); that

Use of Fungi in Pulping Wood / 103

method is based on the formation of color during growth of test strains of

guaiacol-wood meal agar plates. The Biopulping Consortium reported recently

on a more targeted biopulping screening procedure based on the effect of fungal

treatment of coarse pulp on pulp trainability (Leatham and Myers, 1990). The

method could be

used

to predict fungal efficacy insofar as improved paper strength

properties were concerned, but it did not predict energy savings.

An introductory study with Dichomitus squalens (Karst. ) Reid and P.

chrysosporium

B KM F-1767 with aspen wood chips showed large improvements

in the paper strength properties of biomechanical pulps in comparison to the

properties of controls (Myers et al.,

1988). The chips in that study—and in other

studies described here-were initial] y supplemented with glucose, glutamate,

and other nutrients prior to introducing the fungi.

Dichometus squalens was

allowed to decay the wood for 7 weeks, and

P. chrysosporium

for 4 weeks. Even

so, total loss in wood weight was less than

270.

The fungal pretreatment decreased

the brightness (whiteness) of the pulps in this and in all studies to date, which is

somewhat surprising because white-rot fungi are so named because they eventu-

ally bleach wood. Although the pulps are not difficult to bleach, the necessity of

bleaching is a negative aspect of biopulping.

Subsequent studies with additional fungi and aspen wood chips confirmed the

enhancement of paper strength properties and also demonstrated that large energy

savings for the pulping are possible (Leatham et al., 1990a, b.

C

).

The fungi varied

greatly in their effectiveness with aspen.

Trametes versicolor

had essentially no

effect, despite good lignin degradation,

whereas C.

subvermispora, Phlebia

tremellosa

(Schrad.: Fr. ) Nakas. et Burds., and Phlebia brevispora Nakas. were

quite effective. The fungi also varied greatly in their effectiveness for pretreating

aspen compared to pine. Interesting] y, there was little correlation between re-

moval of specific components of the wood by the fungi and efficacy of the fungal

pretreatment for either energy savings or paper strength property improvement.

This is unfortunate because such a correlation could have pointed to more rapid

screening methods. There was also little correlation between energy savings and

paper improvement. indicating that the changes in the wood cell walls that provide

the beneficial effects are different for energy savings and for paper strength

property improvement. Fortunately, pretreatment with some fungi, including

P.

chrysosporium, Phlebia subserialis (Bourd. et Galz. ) Donk, and P. brevispora,

resulted in both energy savings and paper improvement.

Properties of paper from aspen wood pulped by six commercial pulping pro-

cesses and by biomechanical pulping were recently compared. Results showed

that the biomechanical process produced a pulp that is comparable to a chemither-

momechanical pulp in overall properties (Wegner et al., in press).

Over 100 biopulping runs have now been completed on a 2–5-kg scale. Most

of the work has been with P. chrysosporium on aspen and C. subvermispora on

southern pine. Some of the most promising data obtained thus far are given in

Table 7.1. These data are not atypical, but such results are not always obtained,