X-ray optics at NASA Marshall Space Flight Center

Stephen L. O’Dell

a *

, Carolyn Atkins

b

, David M. Broadway

a

, Ronald F. Elsner

a

,

Jessica A. Gaskin

e

, Mikhail V. Gubarev

a

, Kiranmayee Kilaru

c

, Jeffery J. Kolodziejczak

a

,

Brian D. Ramsey

a

, Jacqueline M. Roche

a

, Douglas A. Swartz

a

, Allyn F. Tennant

a

,

Martin C. Weisskopf

a

, and Vyacheslav E. Zavlin

c

a

NASA Marshall Space Flight Center, Huntsville, AL 35812, USA

b

University of Alabama in Huntsville, Huntsville, AL 35899, USA

c

Universities Space Research Association, Marshall Space Flight Center,

Huntsville, AL 35812, USA

ABSTRACT

NASA's Marshall Space Flight Center (MSFC) engages in research, development, design, fabrication, coating,

assembly, and testing of grazing-incidence optics (primarily) for x-ray telescope systems. Over the past two decades,

MSFC has refined processes for electroformed-nickel replication of grazing-incidence optics, in order to produce high-

strength, thin-walled, full-cylinder x-ray mirrors. In recent years, MSFC has used this technology to fabricate numerous

x-ray mirror assemblies for several flight (balloon, rocket, and satellite) programs. Additionally, MSFC has

demonstrated the suitability of this technology for ground-based laboratory applications—namely, x-ray microscopes

and cold-neutron microscopes and concentrators.

This mature technology enables the production, at moderately low cost, of reasonably lightweight x-ray telescopes with

good (15–30 arcsecond) angular resolution. However, achieving arcsecond imaging for a lightweight x-ray telescope

likely requires development of other technologies. Accordingly, MSFC is conducting a multi-faceted research program

toward enabling cost-effective production of lightweight high-resolution x-ray mirror assemblies. Relevant research

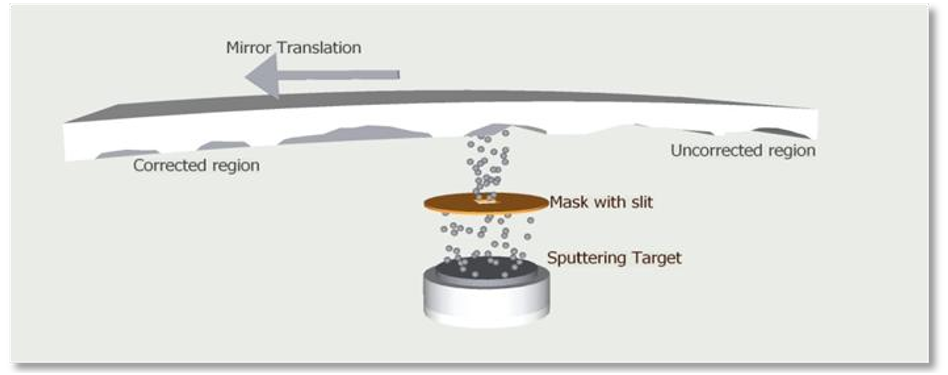

topics currently under investigation include differential deposition for post-fabrication figure correction, in-situ

monitoring and control of coating stress, and direct fabrication of thin-walled full-cylinder grazing-incidence mirrors.

Keywords: X-ray telescopes, electroformed mirrors, x-ray optics, neutron optics, differential deposition, coating stress,

optics fabrication

1. INTRODUCTION

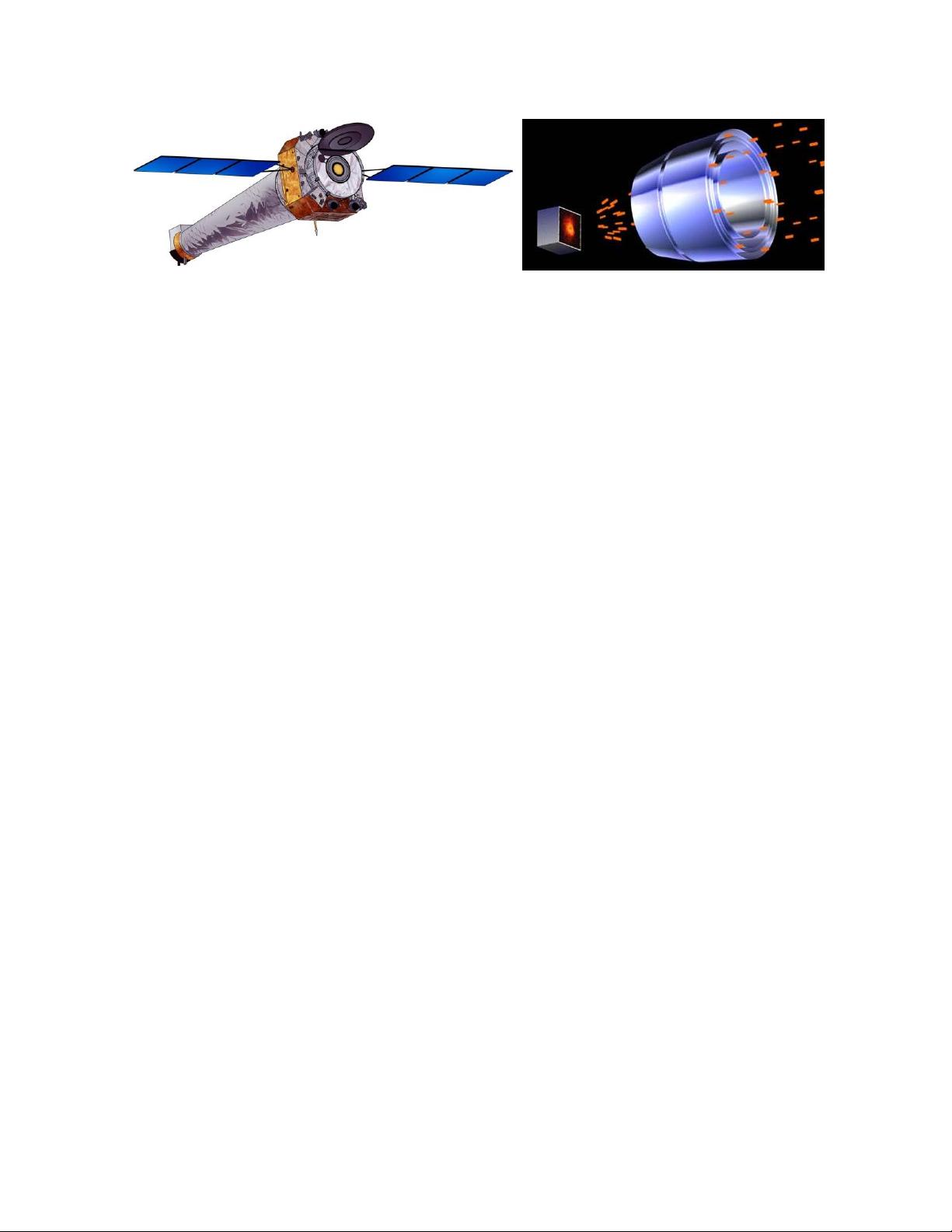

Launched in 1999, the Chandra X-ray Observatory

1,2

(Figure 1, Left) continues as NASA’s flagship mission for x-ray

astronomy. Its four nested, thick-walled, grazing-incidence mirror pairs (Figure 1, Right) uniquely provide sub-

arcsecond x-ray imaging of cosmic sources. Currently, the US x-ray-astronomy community is considering mission

concepts and enabling technologies for a worthy successor to Chandra. The optical performance requirements for this

“X-ray Surveyor” are likely to call for an angular resolution comparable to that of Chandra, with an aperture area 30

times larger.

3

Thus important technological and programmatic challenges

4,5

lie in the fabrication, alignment, and

mounting of lightweight grazing-incidence mirrors into a mirror assembly that affords sub-arcsecond x-ray imaging

with an aperture area ≈ 3 m

2

.

The X-ray Astronomy Team at Marshall Space Flight Center (MSFC) began in 1977 with the arrival Martin Weisskopf

to serve as Project Scientist for the Advanced X-ray Astrophysics Facility (AXAF), which became the Chandra X-ray

Observatory. Since then, the primary responsibility of the Team has been to support of the Chandra Project during

formulation, development, calibration, and operation of Chandra. We here briefly describe MSFC’s in-house research

and fabrication of grazing-incidence optics (primarily) for x-ray telescope systems.

*

Contact author (SLO): stephen.l.odell@nasa.gov; voice +1 (256) 961-7776; fax +1 (256) 961-7522

Postal address: NASA/MSFC/ZP12; 320 Sparkman Drive NW; Huntsville, AL 35805-1912 USA

Figure 1. NASA’s Chandra X-ray Observatory (Left) provides sub-arcsecond x-ray imaging of cosmic sources using four

precision grazing-incidence mirror pairs (Right).

Over the past two decades, MSFC has refined processes for electroformed-nickel replication (ENR) of grazing-

incidence optics (§2). Currently, MSFC uses this technology to produce (§3) x-ray telescopes for sub-orbital (balloon

and rocket) and in-space missions (§3.1), as well as grazing-incidence optics for (ground-based) laboratory applications

(§3.2). The angular resolution of ENR telescopes typically ranges from 15 to 30 half-energy width (HEW). While this

angular resolution suffices for many applications, it does not approach the fine resolution of Chandra that is desired for

an X-ray Surveyor. Consequently, MSFC is also conducting research (§4) toward the goal of lightweight sub-arcsecond

x-ray telescopes. Current research topics include post-fabrication correction of (full-shell and segmented) replica

mirrors (§4.1), control of coating stress (§4.2), and direct fabrication of thin-walled full-shell mirrors (§4.3).

2. ELECTROFORMED-NICKEL REPLICATON (ENR)

Replication copies the surface figure of a precision mandrel onto a complementary mirror. It has two advantages over

direct fabrication (§4.3). First, as the mandrel can be thick-walled and very stiff, it is less susceptible to deformation

during figuring and polishing. Second, as replication itself is inexpensive compared to precision figuring and polishing,

it becomes much more cost-effective to use replicated mirrors if the design calls for several mirrors of the same size and

shape. A disadvantage of replication is that the figure of the replica—especially if the mirror is very thin—does not

perfectly match the shape of the precisely figured mandrel.

The prevalent replication technique for full-shell x-ray mirrors is nickel electroforming, which is used for ESA’s XMM-

Newton

6

and for several smaller satellite

7,8,9,10,11

and sub-orbital

12,13

missions. Pioneered for x-ray optics in Prague

14,15,16

and elsewhere

17,18,19

and refined in Italy,

20,21

MSFC has further improved the process over the past two decades. The

production of replicated x-ray mirrors comprises two top-level procedures—mandrel fabrication (§2.1) and shell

fabrication (§2.2).

2.1. Mandrel fabrication

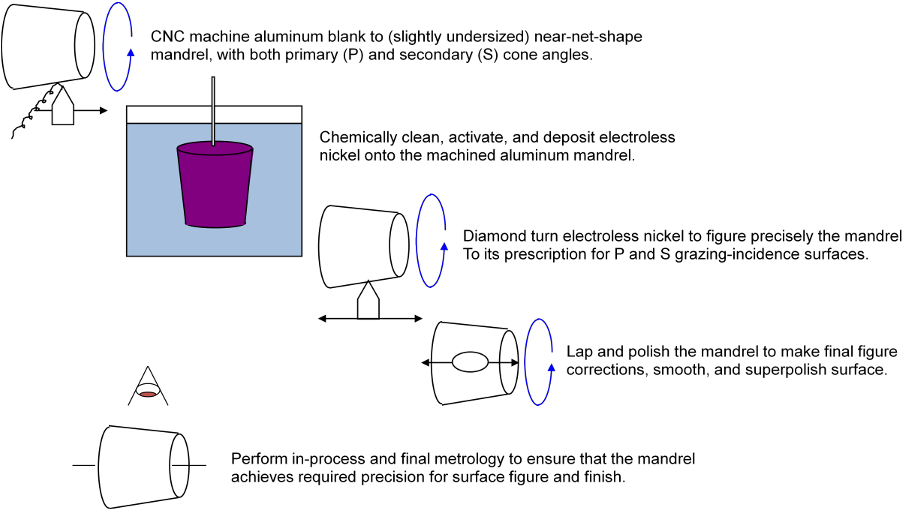

Figure 2 outlines the basic steps in fabricating a precision mandrel for electroformed-nickel replication (ENR) of a full-

shell grazing-incidence mirror. The mandrel typically incorporates primary (P) and secondary (S) conic frusta

monolithically so that the P and S surfaces of a full-shell replica are consequentially coaxial. This feature and the mirror

being a full shell greatly simplify alignment of mirror shells into a mirror assembly. While MSFC usually employs

single-point diamond turning of the electroless nickel to figure the mandrel’s P and S surfaces to the required optical

prescriptions, other figuring processes—e.g., precision grinding—are possible and occasionally used. Final figuring,

smoothing, and superpolishing of the mandrel’s electroless-nickel surface utilize conventional lapping and polishing

methods using a custom precision lathe. Of course, throughout the mandrel fabrication, precision metrology is essential:

“The optic can be no better than the metrology.” To this end, MSFC utilizes a full suite of metrology instrumentation

spanning relevant spatial frequencies and geometries—including a large coordinate-measuring machine, circularity test

stand, Fizeau interferometer, long-trace profilometer, optical surface profiler, and atomic-force microscope.

Figure 2. Basic steps in fabricating a precision mandrel for electroformed nickel replication.

2.2. Shell fabrication

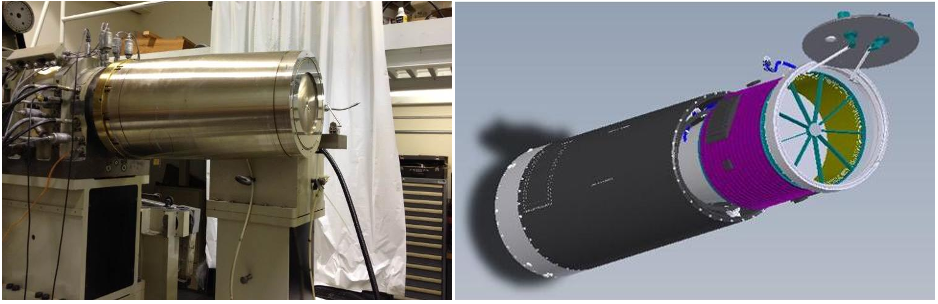

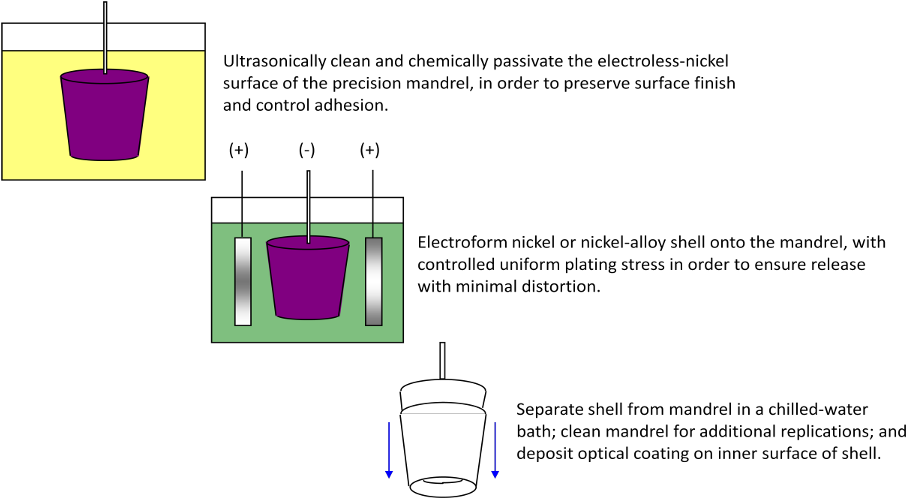

Figure 3 outlines the basic steps in electroforming a nickel replica full-shell grazing-incidence mirror off a precision

electroless-nickel-plated aluminum mandrel (§2.1). Again, the ENR mirrors usually are full shells and incorporate both

(P and S) grazing-incidence surfaces required for true imaging. Over the past two decades, MSFC has developed several

process refinements that now enable the successful fabrication of very thin (≈ 100-m) ENR mirror shells, although

applications typically utilize thicker shells to reduce mount-induced distortions during alignment and assembly.

Figure 3. Basic steps in electroforming a nickel replica full-shell grazing-incidence mirror.

One area of ENR process improvement is surface passivation—control of adhesion of the shell onto the mandrel. If

adhesion is too low, the plating will not stick to the mandrel well enough to form a shell; if too high, the formed shell

will not release in the chilled-water bath.

†

Historically, gold (deposited on the mandrel and transferred to the shell

during replication) served both as a passivating layer and as the optical coating of the mirror. For most x-ray-astronomy

applications, MSFC deposits an iridium optical coating onto the inner surface of the mirror shell after replication, in

order to take advantage of its x-ray reflectance, which is somewhat higher than that of gold. To accomplish this, MSFC

developed a chemical passivation process that allows electroforming nickel directly on an electroless-nickel plated

surface. More recently, MSFC has collaborated with the Smithsonian Astrophysical Observatory (SAO), to demonstrate

the use of a titanium nitride (TiN) as a durable passivation film on mandrels.

22

Such a film is hard, negligibly increases

the surface roughness, and enables deposition onto a mandrel of optical coatings (including multilayers) that adhere to

and release with the shell. This approach is particularly useful for coating small-diameter full shells, which allow

insufficient space for post-fabrication deposition of an optical coating.

A second area of ENR process improvement is control of electroforming stress and its uniformity.

23

To avoid lifting the

shell off the mandrel during electroforming, the deposition stress must be slightly tensile. In extreme instances, the

deposition stress may be so tensile that the shell will not release upon cooling. Typically, the tensile stress is small and

the shell separates; however, even a small residual tensile stress causes the ends of the mirror shell to hook inwards. If

the electroforming stress is just slightly tensile but uniform, distortion by the residual stress is confined to a small region

at the ends of the mirror shell and has little effect upon customary optical performance metrics—half-energy width

(HEW) and full-with at half maximum (FWHM),

A third area of ENR process improvement is development of nickel-alloy platings that exhibit a much higher precision

elastic limit (or micro-yield strength) than does pure nickel. Consequently, these nickel-alloy shells are significantly less

susceptible than pure-nickel shells to plastic deformation during release and handling. With these and other process

improvements, MSFC can produce very thin (≈ 100-m) ENR mirror shells of good (10–20 arcsecond) intrinsic angular

resolution. Nevertheless, as thinner shells are more susceptible to mounting distortion, a general guideline is to make

shells no thinner than the application requires—e.g., due to mass or filling-factor constraints.

3. PRODUCTION OF ENR GRAZING-INCIDENCE OPTICS

While MSFC is continuing research to improve further the performance of ENR grazing-incidence mirror systems, it

has and is currently producing x-ray mirror systems for several (sub-orbital and space) x-ray telescopes (§3.1) and for

(ground-based) laboratory applications (§3.2).

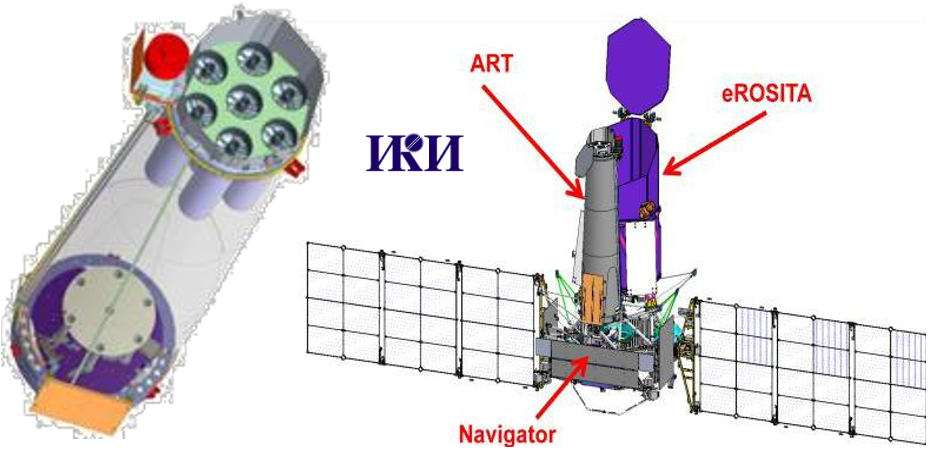

3.1. X-ray telescopes

MSFC has produced numerous flight x-ray mirror modules for several balloon, rocket, and satellite missions. In most

cases, the telescope system comprises multiple ENR mirror assemblies and corresponding detectors, to benefit from the

substantial cost savings in optics fabrication afforded by replication. Furthermore, for a given mass allocation, multiple

mirror assemblies allow relatively stiffer mirrors than does a single mirror assembly with the same collecting area.

3.1.1. High-Energy Replicated Optics to Explore the Sun (HEROES)

HEROES is a joint balloon mission of MSFC and Goddard Space Flight Center (GSFC), designed to perform hard-x-

ray (25–75 keV) imaging of the sun (during the day) and of cosmic sources (during the night). Flown in 2013

September, the HEROES payload (Figure 4) includes 8 mirror assemblies with 6-m focal length. Each mirror assembly

contains 14 coaxially nested iridium-coated ENR shells of 610-mm total (P+S) length and ranging in diameter from 50

mm to 94 mm. The half-energy width of the mirror assemblies is typically HEW ≈ 30 arcsec.

24

The HEROES payload is an enhanced version of MSFC’s High-Energy Replicated Optics (HERO) payload, modified

by GSFC to allow hard-x-ray observations of the sun. The original (proof-of-concept) HERO balloon flight in 2001

May obtained the first hard-x-ray focused images of cosmic sources, using just 2 modules of 3 ENR mirrors each.

25,26

†

Release of the shell from the mandrel upon cooling relies upon the shell material (nickel or a nickel alloy) having a

substantially lower coefficient of thermal expansion (CTE) than the predominant mandrel material (aluminum).

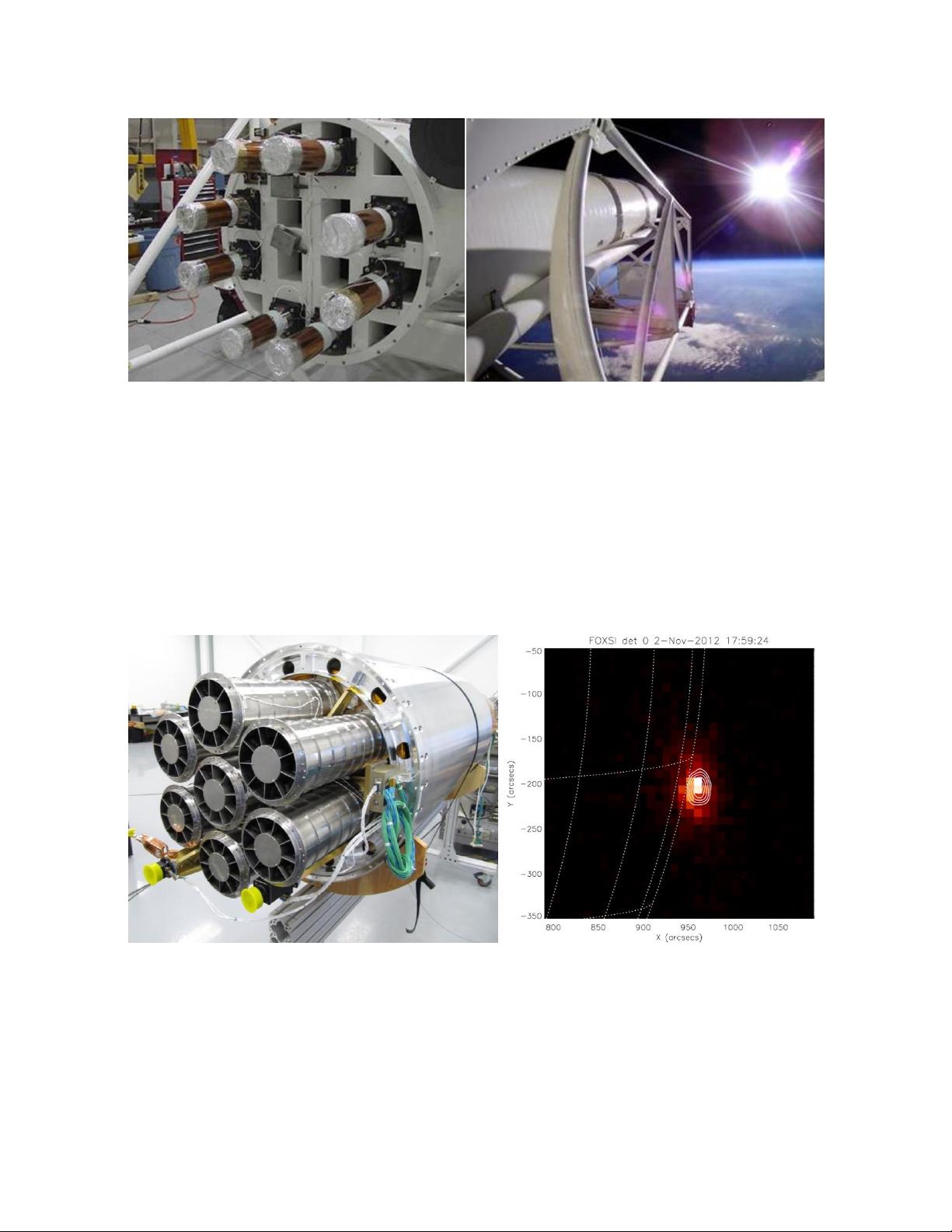

Figure 4. High-Energy Replicated Optics to Explore the Sun (HEROES), showing the telescope’s 8 mirror assemblies

(Left) and an in-flight picture of the telescope pointed toward the sun for heliospheric observations (Right).

3.1.2. Focusing Optics X-ray Solar Imager (FOXSI)

FOXSI is a sub-orbital rocket mission led by the University of California at Berkeley, using x-ray optics from MSFC

and detectors from JAXA’s Institute of Space and Astronautical Science.

27

Designed to perform high-dynamic-range

medium-energy x-ray (5–15 keV) imaging of the sun for the study of x-ray microflares, FOXSI has thus far had two

successful flights—FOXSI-1 in 2012 November

28

and FOXSI-2 in 2014 December. The FOXSI telescope (Figure 5)

includes 7 mirror assemblies with 2-m focal length. For FOXSI-1 (FOXSI-2), each mirror assembly contains 7 (10)

coaxially nested iridium-coated ENR shells of 600-mm P+S length and ranging in diameter from 76 (63) mm to 103

mm. The mirror assemblies exhibit an imaging performance with HEW ≈ 25 arcsec and FWHM ≈ 5 arcsec, the later

metric being more important for this application.

Figure 5. Focusing Optics X-ray Solar Imager (FOXSI), showing the telescope’s 7 mirror assemblies (Left) and an image

of a solar microflare (Right) obtained during the first FOXSI flight.

3.1.3. Micro-X

Micro-X is a sub-orbital rocket mission led by the Massachusetts Institute of Technology (MIT), designed to obtain

soft-x-ray (0.2–3 keV) non-dispersive high-spectral-resolution imaging of supernova remnants.

29

Built in collaboration

with Goddard Space Flight Center (GSFC) and the National Institute of Standards and Technology (NIST), the detector