Moving

Towards

a

More

Electric

Aircraft

J.A.

Rosero,

J.A.

Ortega,

E.

Aldabas,

&

L.

Romeral

ABSTRACT

The

latest

advances

in

electric

and

electronic

aircraft

technologies

from

the

point

of

view

of

an

"all-elect~ric"

aircraft

are

presented

herein.

Specifically,

we

describe

the

concept

of

a

"More

Electric

Aircraft"

(MEA),

which

involves

removing

the

need

for

on-engine

hydraulic

power

generation

and

bleed

air

off-takes,

and

the

increasing

use

of

power

electronics

in

the

starter/generation

system

of

the

main

engine.

Removal

of

the

engine

hydraulic

pumps

requires

fully-operative

electrical

power

actuators

and

mastery

of

the

flight

control

architecture.

The

paper

presents

a

general

overview

of the

electrical

power

generation

system

and

electric

drives

for

the

MIEA,

with

special

regard

to

the

flight

controls.

Some

discussion

regarding

the

interconnection

of

nodes

and

safety

of

buses

and

protocols

in

distributed

systems

is

also

presented.

INTRODUCTION

Conventional

aircraft

architectures

used

for

civil

aircraft

embody

a

combination

of

systems

dependent

on

mechanical,

hydraulic,

pneumatic,

and

electrical

sources.

The

resulting

conventional

equipment

is

the

product

of

decades

of

development

by

system

suppliers.

In

a

conventional

architecture

(Figure

1

is

a

basic

schematic)

fuel

is

converted

into

power

by

the

engines.

Most

of

this

power

is

used

as

propulsive

power

to

move

the

aircraft.

The

remainder

is

converted

into

four

main

forms

of

non-propulsive

power

[1]:

Pneumatic

power,

obtained

from

the

engines'

high-pressure

compressors.

This

kind

of

energy

is

conventionally

used

to

power

the

Refereeing

of

this

work

was

handled

by

L.M.

Kaplan.

Manuscript

received

November

30,

2005;

revised

May

23.

2006.

Author's

Currnt

Address;

LA.

Rosero,

J.A. Ortega,

E.

Aldabas,

&

L.

Romeral

0885/8985/07/

USA

$25.00

0

2007

IEEE

IEEE

A&E

SYSTEMS

MAGAZINE,

MARCH

2007

Environmental

Control

System

(ECS)

and

supply

hot

air

for

Wing

Anti-Icing

(WAI)

systems.

Its

drawbacks

are

low

efficiency

and

a

difficulty

in

detecting

leaks.

"

Mechanical

power,

which

is

transferred

(by

means

of

the

mechanical

gearboxes)

from

the

engines

to

central

hydraulic

pumps,

to

local

pumps

for engine

equipment

and

other

mechanically

driven

subsystems,

and

to

the

main

electrical

generator.

"

Hydraulic

power,

which

is

transferred

from

the

central

hydraulic

pump

to

the

actuation

systems

for

primary

and

secondary

flight

control;

to

landing

gear for

deployment,

retraction,

and

braking;

to

engine

actuation;

and

to

numerous

ancillary

systems.

Hydraulic

systems

have

a

high

power

density

and

are

very

robust.

Their

drawbacks

are

a

heavy

and

inflexible

infrastructure

(piping)

and

the potential

leakage

of

dangerous

and

corrosive

fluids.

"

Electrical

power,

which

is

obtained

from

the

main

generator

in

order

to

power

the

avionics,

cabin

and

aircraft

lighting,

galleys,

and

other

commercial

loads

(such

as

entertainment

systems).

Electrical

power

does

not

require

a

heavy

infrastructure

and

is

very

flexible.

Its

main

drawbacks

are

that

conventionally

it

has

a

lower

power

density

than

hydraulic

power,

and

results

in

a

higher

risk

of

fire

(in

the

case

of

a

short

circuit).

Each

system

has

become

more

and

more

complex,

and

interactions

between

different

pieces

of

equipment

reduce

the

efficiency

of

the

whole

system.

A

simple

leak

in

the

pneumatic

or

hydraulic

system

may

lead

to

the

outage

of

every

user

of

that

network,

resulting

in

a

grounded

aircraft

and

flight

delays.

The

leak

is

generally

difficult

to

locate

and

once located

it

cannot

be

accessed

easily.

The

trend

is

to

move towards

"all-electric"

aircraft,

which

means

that

all

power

off-takes

from

the

aircraft

are

electrical

in

nature,

thus

removing

the need

for

on-engine

hydraulic

3

Fligh~t

Hydraulic

Power

Mechanical

kaloN

Power

r

Elcrc

Electrical

Geeao,

Power

Ice

Protection

Pneumatic

Comfpressor

Power

ECS

approaches

to

on-board

energy

power

management

and

drive

systems

(Figure

3).

These

are

now

being

carefully

considered,

and

it

is

believed

that

electrical

systems

have

far

more

potential

for

future

improvement

than

conventional

ones

regarding

energy

efficiency.

fIot __, Ulvt

o

Fig.

1.

Schematic

of

conventional

power

distribution

power

generation

and

bleed

air

off-takes.

The

removal

of

bleed

air

off-takes

requires

new

high-voltage

electrical

networks

and

new

solutions,

such

as

air-conditioning,

wing

ice

protection,

or

electric

engine

start-up.

Removal

of

the

engine

hydraulic

pumps

requires

fully-operative

electrical

power

actuators

and

a

mastery

of

flight

control

architecture.

The

"all-electric"

aircraft

is

not

a

new

concept:

the

concept

of

an

electric

aircraft

has

been

considered

by

military

aircraft

designers

since

World

War

11

[2],

although

until

recently

the

lack

of electrical

power

generation

capability,

together

with

the

volume

of

the

power conditioning

equipment

and the

advanced

control

required,

rendered

the

approach

unfeasible

-

especially

for

commercial

and

civil

transport

applications.

Since

the early

1990s,

research

into

aircraft

power

system

technologies

has

advanced

with

the

aim

of

reducing

or

eliminating

centralized

hydraulics

aboard

aircraft

and

replacing

them

with

electrical

power.

Several

programs

have

been

started

with

the

aim

of

driving

the

research

on

this

field

[3],

such

as

Totally

Integrated

More

Electric

Systems

(TIMES),

devoted

to

use

previously

developed

systems

into

electrical

aircraft,

US

Air

Force

MEA

Program

that

investigates

for

providing

more

electrical

capability

for

fighter

aircrafts,

and

Power

Optimized

Aircraft

(POA),

which

tries

to

optimize

the

management

of

electrical

power

on

aircraft

in

order

to

reduce

non-propulsive

power

and

reduce

fuel

consumption,

while

increasing

the

reliability

and

safety

of

onboard

systems

and

reducing

maintenance

costs.

Nowadays,

novel

ways

of

generating.

distributing,

and

using

power

onboard

are

examined

at

the

aircraft

level.

Hybrid

or

bleed-less

air

conditioning

systems,

"More

Electric

Engines"

(MEEs),

fuel

cells,

variable

frequency

generators,

complex

embedded

digital

systems

and

distributed

system

architectures

are

just

a

few

of

the

technologies

vying

for

space

on

forthcoming

aircraft;

the

concept

is

known

as

"More

Electric

Aircraft"

(MEA)

as

presented

in

Figure

2.

Recently,

worldwide

research

into

the

future

development

of

commercial

aircraft

has

given

rise

to

more

advanced

Fig.

2.

Current

trends toward

the

MEA

Power

ft

Au

Compressor

P a

Fig.

3.

Schematic

of

MEA

Power

Distribution

Steps

toward

a

MEA

are

being

taken

in

two

different

ways:

"

Removing

current

air

and

hydraulic

engines

and

further

increasing

electrical

power

generation

capability.

This

requires

significant

changes

in

electrical

generation

and

network

techniques,

and

in

fault protection.

*

Substituting

hydraulic

actuators

for

electromechanical

actuators.

This

reduces

weight

and

decreases

maintenance

and

production

costs.

The

MEA

initiative

emphasizes

the

utilization

of

electrical

power

in

place

of

hydraulic,

pneumatic,

and mechanical

power

to

optimize

the

performance

and

life cycle

cost of

the

aircraft.

The

MEA

requires

a

highly

reliable,

fault

tolerant,

autonomously

controlled

electrical

power

system

to

deliver

higher

quality

power

and

electrical

levels

to

the

aircraft's

4

IEEE

A&E

SYSTEMS

MAGAZINE,

MARCH

2007

Loa

_J s

111111111111010.

Engine

syýpenis

OMMOMMM+

Ice

Protection

- I

EC

8

4

Central

Hydraulic

Pump

Flight

controls

loads. Also, reliable

high

integration

and

safety

of

the

electrical power system leads

to

the use

of

distributed

generation

and control

architecture.

The advantages of

More

Electric

systems

are

not

confined

to aircraft.

Other

transport

systems,

such

as

marine

propulsion,

are

also

moving

in

this

direction

[4].

The

next

sections

briefly

discuss

a

general overview

of

the

electrical

power

generation system

and electric

drives

on the

MEA,

especially

with

regard

to

the

flight

controls.

A

brief

introduction

to

the

safety

aspects

of

the

flight

controls

has

also

been

included.

ELECTRONIC

POWER

SYSTEMS

The first factor

to

take

into

account

is

the

large

amount

of

power

electronics

for

power

conversions

and

power users

that

MBA

will

involve:

at

least

1.6

MW

for

a

next-generation

300

pax

aircraft. The

development

of

efficient

and

secure

power electronics

technologies

is

a

great challenge.

However,

not

only are

power

electronics

necessary,

but

also

efficient

control

of

the

electronics

must

be

developed.

One

major evolutionary

technological advance

that

has

contributed

greatly

to

the

feasibility

of

an

electric

aircraft

non-propulsive

power

system

has

been

the

development

of

reliable, solid-state,

high

power-density,

power-related

electronics. Generator

power

control

units,

inverters,

converters,

and

motor

controllers

consist

of

state-of-the-art

silicon-based

power

semiconductor

switching devices

that

include

integrated

gate

bipolar

transistors

(IGBTs). It

is

expected

that advanced

composition,

high-performance

multi-layer

ceramic capacitors

will

dramatically improve

the

power

density

of

future

inverters,

converters,

and

motor

controllers. Improved, high-efficiency

electric

circuit

topologies

are

also

the

subject

of

on-going

research.

Some

of

the

higher

power

level

equipment

is

actively

cooled

through

the

use

of

oil

circulation

or

forced

air

convection.

The

extent

of

the

use

of

active,

fluid-based

cooling

systems

is

extremely

application-specific

and

is

yet

to

be

determined.

Lightweight,

simplified, passive

(non-pumped

fluid-based)

thermal

management

techniques

are

also

a

focus

of

research

and

will

be used,

wherever

feasible,

to

maintain

high

reliability.

Power

Distribution

and

Management

Systems

(PDMS)

provide

fully

automatic monitoring,

control, protection,

and

switching

of

aircraft

electrical loads

under

normal

and

emergency

conditions

with

load

management,

including

automatic

load

shedding

and

restoration,

to

make

best

use

of

available

power.

These

systems

comprise

the

Primary Power

Buses,

located close

to the

generators,

with

high

power

contactors

and

circuit

breakers,

and the

Secondary

Power

Distribution

Buses,

located

in

the avionics bay,

which

provide

the

monitoring

and

control

of

the

system,

and

contain

some

same

circuit

breakers

and

remote

power

switches.

The

use

of

programmable

solid-state

devices

and

switching

power

devices

in

place

of

traditional

electromechanical circuit

breaker

technology provides

benefits

to

the

aircraft

in

terms

of

load

management,

fault

isolation,

diagnostic

health

monitoring,

and

improved

flexibility

to

accommodate

modifications

and

system

upgrades.

With these advancing technologies,

it

will

be

feasible

to

use

high

power-density

electrical

power components

to

drive

the

majority

of

aircraft

subsystems. These

will

become

easier

to

maintain (supported

by

less

equipment

and

manpower),

more durable,

lower

in

cost,

and

higher

in

performance.

The

engine primarily provides

thrust,

but

it

also

produces

all

other

power

(Figure

1).

In

a

MEA,

current

engine

accessories

that

derive power form

gearbox

mounted

pumps

will be

replaced

with

electronically-driven

electrical

machines. Vibration

resistance,

electromagnetic

compatibility,

and

size

constraints

are

key

design challengers

of

embedding

electrical machines

into

the

engine.

The

integration

into

a

harsh

environment

of engine

off-takes

for

aircraft

system

needs

without

significantly affecting

engine

performance

is

also

a

difficult

task.

By

deleting

air off-takes,

virtually

the

only

requirement

the

engines have

to

satisfy

is

to

provide electrical

power.

Whilst

the

hot-air

bleed

ducts

and the

pre-cooler

are

removed,

several

other

integration

issues arise, such

as

generator

thermal management, mechanical

integration,

new

electric starting

requirements,

and

electrical

power

conversion,

(whether

the

chosen

solution

is

a

conventional

gearbox-mounted

generator

or

an

embedded

power-optimized

generator).

Conceptually,

electrical

power

for

an MEA

would

be

produced

by

a

starter/generator directly

driven

by

the

gas

generator

spool

of

the

main

engine.

Power

is

transferred

out

of

the

engine through

wires

that

feed

into

a

fault-tolerant

electrical

network

to

drive

the

aircraft

subsystems.

Electronic

power

converters

would

transform

the

electrical

power

and

no

accessory gearboxes

would

be

necessary.

Elimination

of

gearing

and

associated

gear

separation forces

enhances

the

use

of

advanced

magnetic bearing

systems

[5]1,

which

could

be integrated

into

the

internal

starter/generator

for both

the

main engine

and

auxiliary

power

units.

For

many

years, electrical

power

for

aerospace

applications

has

been

generated

using

a

variable

ratio

gearbox-mounted

wound-field

synchronous

machine

to

obtain

a

three-phase

115

V

AC

system

at

a

constant

frequency

of

400

Hz.

This

machine

is

known

as

a

Constant

Frequency Integrated Drive

Generator

(IDG),

and today

it

is

still

the

most

commonly

used.

However,

operating

experiences

under

the

new

requirements

of

lower

cost,

increased

reliability, easier maintenance, and

higher

operating

speed and

temperatures have

shown

that

a

replacement

for

the

gearbox

using

power

electronics has

obvious advantages.

A

high

quality

three-phase

AC-DC

conversion

plus

subsequent

DC-AC

conversion

is

one

of

the

steps involved

in

achieving

these

objectives.

The

resulting

system

is

known

as

variable speed

constant

frequency

(VSCF)

system, and

it

results

in

promising technology

that

meets these

requirements.

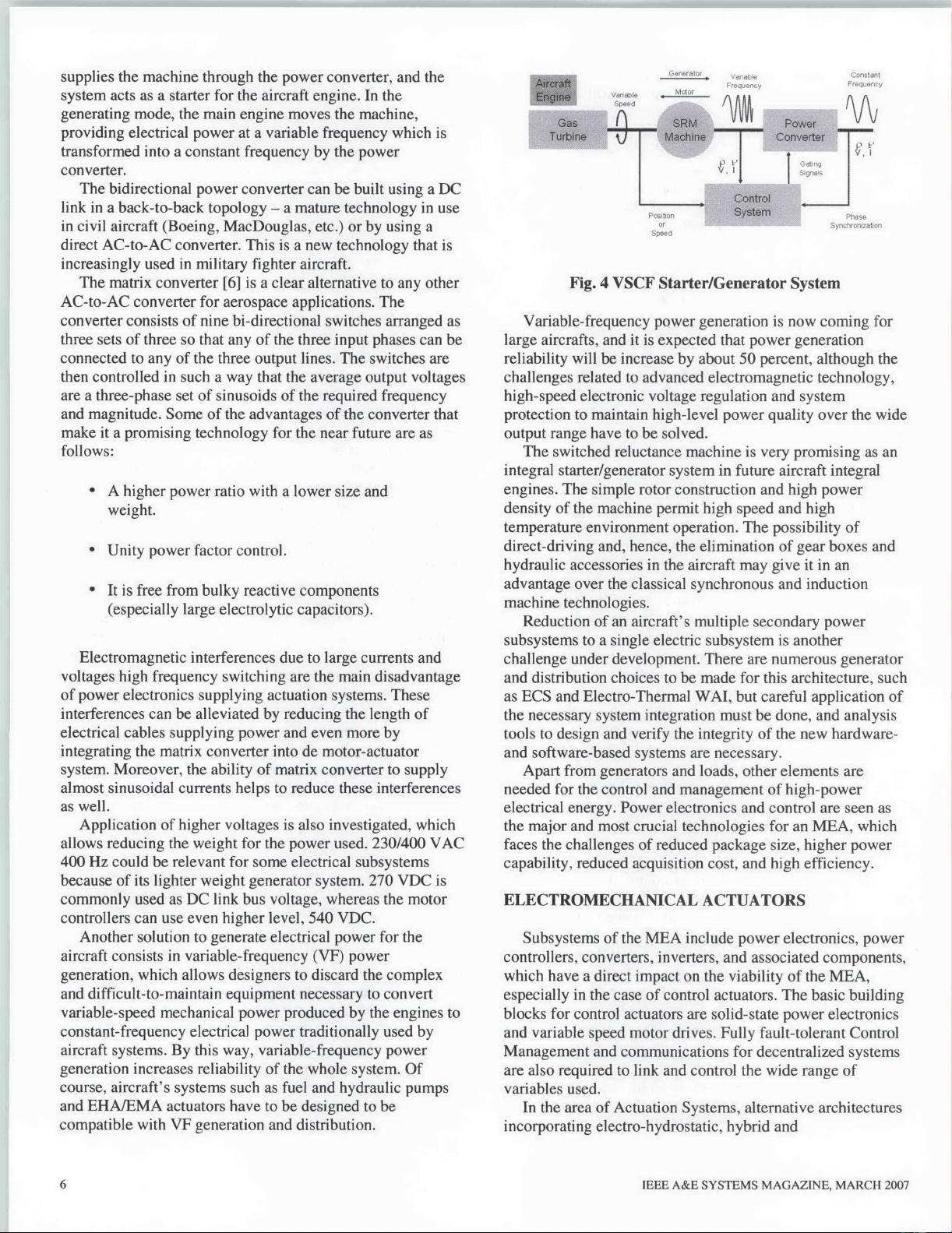

Figure

4

shows

a

typical

block

diagram

of

a

VSCF

system.

In

the

motoring

mode,

the

constant

frequency system

IEEE

A&E

SYSTEMS

MAGAZINE, MARCH

20075

5

supplies

the

machine

through

the

power

converter,

and

the

system

acts

as

a

starter for

the

aircraft

engine.

In

the

generating

mode, the

main

engine

moves the

machine,

providing

electrical

power

at

a

variable

frequency

which

is

transformed

into

a

constant

frequency

by

the

power

converter.

The

bidirectional

power converter

can

be

built

using

a

DC

link

in

a

back-to-back

topology

- a

mature

technology

in

use

in

civil

aircraft (Boeing,

MacDouglas,

etc.)

or

by

using

a

direct

AC-to-AC

converter.

This

is

a

new

technology

that

is

increasingly

used

in

military

fighter

aircraft.

The

matrix

converter

[6]

is

a

clear alternative

to

any

other

AC-to-AC converter

for

aerospace

applications.

The

converter consists

of

nine

bi-directional

switches arranged

as

three sets

of

three

so

that

any

of

the

three

input phases

can

be

connected

to

any

of

the

three

output

lines.

The

switches

are

then

controlled

in

such

a

way

that

the

average

output

voltages

are

a

three-phase

set

of

sinusoids;

of

the

required

frequency

and

magnitude.

Some

of

the

advantages

of

the

converter

that

make

it

a

promising

technology

for

the

near

future

are

as

follows:

"

A

higher

power

ratio

with

a

lower

size

and

weight.

"

Unity

power

factor

control.

"

It

is

free from

bulky reactive

components

(especially

large

electrolytic

capacitors).

Electromagnetic

interferences

due

to

large

currents

and

voltages

high

frequency

switching

are

the

main

disadvantage

of power

electronics

supplying

actuation systems.

These

interferences

can

be

alleviated

by

reducing

the length

of

electrical

cables

supplying

power

and even

more

by

integrating

the

matrix

converter

into de

motor-actuator

system.

Moreover,

the

ability

of

matrix

converter

to

supply

almost

sinusoidal currents

helps

to

reduce

these

interferences

as

well.

Application

of

higher

voltages

is

also

investigated,

which

allows

reducing

the

weight

for

the

power

used.

230/400

VAC

400

Hz

could

be

relevant

for

some

electrical

subsystems

because

of

its

lighter

weight

generator

system.

270

VDC

is

commonly

used

as

DC

link

bus

voltage,

whereas

the

motor

controllers

can

use

even

higher

level,

540

VDC.

Another

solution

to

generate

electrical

power

for

the

aircraft

consists

in

variable-frequency

(VF) power

generation,

which

allows

designers

to discard

the

complex

and

difficult-to-maintain equipment

necessary

to

convert

variable-speed

mechanical

power

produced

by

the

engines

to

constant-frequency

electrical

power traditionally

used

by

aircraft systems.

By

this

way,

variable-frequency power

generation

increases reliability

of

the whole

system.

Of

course,

aircraft's

systems

such

as

fuel

and

hydraulic

pumps

and

EHA/EMA

actuators

have

to

be

designed

to

be

compatible

with

VF

generation

and

distribution.

Yelrtr

V-rable

O-tart

Frenuert

Frequer

Speed

Fqcontrol

Or

Syncroflrizabon

Speed

Fig.

4

VSCF

Starter/Generator

System

Variable-frequency

power

generation

is

now

coming

for

large

aircrafts,

and

it

is

expected

that

power generation

reliability

will

be

increase

by

about

50

percent,

although

the

challenges

related

to

advanced

electromagnetic

technology,

high-speed

electronic

voltage

regulation

and

system

protection

to

maintain high-level

power quality

over

the wide

output

range have

to

be

solved.

The

switched

reluctance

machine

is

very

promising

as an

integral

starter/generator

system

in

future

aircraft

integral

engines.

The

simple

rotor

construction

and high

power

density

of

the

machine permit

high

speed

and

high

temperature

environment

operation. The

possibility

of

direct-driving

and,

hence,

the

elimination

of

gear

boxes

and

hydraulic

accessories

in

the

aircraft

may

give

it

in

an

advantage

over

the

classical

synchronous

and

induction

machine

technologies.

Reduction

of

an

aircraft's

multiple

secondary

power

subsystems

to

a

single

electric

subsystem

is

another

challenge

under

development.

There

are

numerous

generator

and

distribution

choices

to be

made

for

this

architecture,

such

as

ECS

and

Electro-Thermal

WAI, but

careful

application of

the necessary

system

integration

must

be done,

and

analysis

tools

to

design

and

verify

the

integrity

of

the

new

hardware-

and

software-based

systems

are

necessary.

Apart

from generators

and

loads,

other

elements

are

needed

for

the

control and

management

of

high-power

electrical

energy.

Power

electronics

and

control

are

seen

as

the

major

and

most

crucial

technologies

for

an

MEA,

which

faces

the

challenges

of

reduced

package

size,

higher power

capability,

reduced

acquisition

cost,

and

high

efficiency.

ELECTROMECHANICAL

ACTUATORS

Subsystems

of

the

MEA

include

power

electronics,

power

controllers,

converters,

inverters,

and

associated

components,

which

have

a

direct

impact

on

the

viability

of

the

MEA,

especially

in

the case

of

control

actuators.

The

basic

building

blocks

for

control

actuators

are

solid-state

power

electronics

and variable

speed

motor

drives.

Fully fault-tolerant

Control

Management

and

communications

for

decentralized

systems

are

also

required

to

link

and

control

the

wide

range

of

variables

used.

In

the

area

of

Actuation Systems,

alternative

architectures

incorporating

electro-hydrostatic,

hybrid

and

6

IEEE

A&E

SYSTEMS

MAGAZINE,

MARCH

2007

6

electromechanical

actuation

for

primary

and

secondary

flight

control

(as

well

as

new

landing

gear,

braking,

nacelle

actuation,

and

horizontal

stabilizer

architectures)

are being

examiined.

A

large

number

of

actuators

have

been

studied,

most

of

them

electromechanical

except

flight

control

actuators

due

to

the

showstopper

jamm-ing

case.

In

the

last

decade,

a

lot of

research

has

allowed

Electro-Hydrostatic

Actuator

(EHA)

technology

to

be

mastered.

One

result

of

this

on

new

aircraft

such

as

the

Airbus

A380

or

Boeing

B7E7

is

the

replacement

of

the

hydraulic

circuits

by

EHA

networks.

These

are

used

as

a

back-up

for

other

hydraulic

systems,

although

there

is

increasing

interest

in

the

use

of

electric

drives

to

substitute

hydraulics

and

electro-hydraulic

systems

in

aircraft.

In

such

systems,

an

electric

motor

directly

drives

a

pump,

a

fan,

or

an

actuator.

I---------------------------------------------

'Superv/ision

Subsystem

------------------------

I

II

I

Poe--4

ioq,-

See]

-op

7

Iovetr

ICirfe

orme

000

Motion

Subsystem

Fig.

5.

Direct

Drive

architecture

for

EMA

In

fact, the

next

step

from

the

present

hydraulic

or

electro-hydraulic

actuation

(EHA)

in

a

centralized

system,

to

the

use

of

Electromechanical

Actuators

(EMAs)

in

de-centralized

systems

(while

maintaining

the

same

level

of

safety)

is

today

of

major

importance

for

aeronautics.

The

objective

is

to

reduce

production

and

maintenance

costs.

Furthermore,

these

highly

safe

and

reliable

EMA

technologies,

which

are

jamming

free,

will

help

to

satisfy

the

social

demand

for sustainable

transport.

EMA

technologies

are

already

being

used

in

aeronautics,

but

for

safety

reasons

they

are

limited

to

Secondary

Flight

Controls

or

military

aircraft

[7].

Their

application

to

Primary

Flight

Controls

will

allow

reductions

in

the

weight

of

drives,

gas

consumption,

and

polluting

emissions.

The

major

step

in

moving

from

EHAs

to

jam-free

EMAs

is

the

prevention

of

potential

jamming

cases

by

appropriate

technology

and

monitoring,

thus

giving

the

system

aircraft

availability

for

dispatch

and

failure

sizing

cases.

Electromechanical

Actuator

drives

for

flight

controls

are

based

on

a

Direct

Drive

architecture

built

up

by

an

electric

motor,

(usually

a

Permanent

Magnet

Synchronous

Motor,

PMSM)

directly

connected

to

the

roller-screw

that

moves

the

actuator

(Figure

5).

The

power

stage

can

be

built

up

either

by

standard

inverters

or

by

new

matrix

converter

architectures.

The

complete

control

block

diagram

for

an

EMA

drive

includes

the

position,

speed,

torque

and

flux

controls,

and

also

the

supervisory

and

communication

systems.

From

the

previous

statements,

it

is

clear

that

not

only

power

electronics,

but

also

electric

machines,

are

becoming

more

and

more

important

in

the

general

electric

aircraft

power

system,

both

for

generation

and

load

control.

Specifically,

the

PMSM

is

increasingly

being

used

for

actuator

drives,

due

to

its

high

efficiency

throughout

the

full

speed

range,

high

power

ratio,

and

ease

of

refrigeration,

compared

to

classical

wound

machines

[8].

The

drive operating

the

flight

control

must

ensure

continuity

in

operation

even

in

the

case

of

a

fault. Dual

redundant

power

drive

electronics

providing

motor

drive,

speed

closed-loop,

and

control

management

can

help

to

overcome

this

issue.

With more

electronics

in

the

actuators,

it

is

also

possible

to

predict

how

long

an

actuator

will

last,

introducing

the

predictive

maintenance

instead

of

preventive

maintenance

today

used

by

airlines.

The

drive

should

also

be

able

to

diagnose

and

report

the

nature

of

the

fault.

The

system

must

also have

the

following

general

characteristics

[9]:

"

Testability,

to

make

verification

and

real-time

check-out

easier.

*

Reduced

complexity

and

low

maintenance

costs,

by

the

decomposition

of

the

main

CPU

into

smaller

distributed

controls

for

every

EMA,

many

of

them

consisting

of

identical

hardware.

"

Intelligent

software

running

in

every

control

node,

which

must

be

able

to

exchange

information

by

means

of

standard

interfaces.

To

achieve

the

above

specifications,

control

and

diagnosis

of

the

EMA

needs

to

rely

on

modem

electronics.

As

in

other

fields,

digital

computer

control

systems

have

been

incorporated

into

aircraft

avionics

system

design.

Digital

systems

are

more

reliable,

lighter

and

more

adaptable

to

change

or

modifications,

as

well

as

providing

self-test

capability.

For

these

reasons,

embedded

digital

control

systems

are

going

to

be

extensively

used

in

the

aeronautical

industry.

The

growth of

electronics

has

also

led

to

drive-by-wire

control

systems

in

which

there

are

no

physical

connections

(mechanical,

pneumatic,

or

hydraulic)

between

sensors,

controls,

and

actuators.

Similarly,

a

fly-by-wire

(FBW)

IEEE

A&E

SYSTEMS

MAGAZINE,

MARCH

20077

7