Estimation of filament temperature and adhesion development in fused deposition techniques

TLDR

In this paper, an analytical solution to the transient heat conduction developing during filament deposition in Fused Deposition Techniques (FDT), which is coupled to a routine that activates or deactivates all relevant local boundary conditions depending on part geometry, operating conditions and deposition strategy, is presented.About:

This article is published in Journal of Materials Processing Technology.The article was published on 2017-07-01 and is currently open access. It has received 180 citations till now. The article focuses on the topics: Protein filament & Deposition (phase transition).read more

Figures

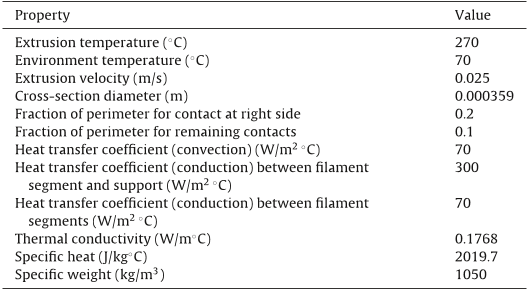

Table 1 Process parameters and material properties.

Table 2 Material properties of ABS FA 4475.

Fig. 5. Geometry and deposition sequence used to illustrate the results of the calculations (dimensions in mm).

Fig. 6 shows the filament temperature at various instants of he deposition process (an animated view of cooling can be creted). Clearly, the newest filament segment or elementary length s always the hottest one and cools down gradually, although the ffect of the physical contacts is difficult to perceive in this repreentation. The phenomenon is better seen in Fig. 7, which depicts he time evolution of the temperature of filament segments 1–9 t a vertical xx plan distant 0.05 m from the origin (see Fig. 5). As a ew filament segment is deposited, the temperature of the adjacent egments increases and so their cooling is delayed. The physical ontacts can alter local filament temperatures by as much as 18 ◦C.

Fig. 15. Temperature evolution with time (at x = 40 mm) of a filament segment deposited on top of another (die set to 200 ◦C and 220 ◦C).

Fig. 7. Time evolution of the temperature of filament segments 1–9 for the geometry and deposition sequence illustrated in Fig. 5, at a vertical xx plan distant 0.05 m from the origin.

Citations

More filters

Journal ArticleDOI

Numerical investigation of the influence of process conditions on the temperature variation in fused deposition modeling

TL;DR: In this article, an adaptable three-dimensional transient mathematical model of temperature variation with respect to space and time, during and after the fused deposition modeling (FDM), is proposed and applied with a boundary-adjusting finite difference method.

Journal ArticleDOI

Experimental validation of a numerical model for the strand shape in material extrusion additive manufacturing

TL;DR: In this article, the influence of the processing conditions on the cross-section of a strand printed by material extrusion additive manufacturing is investigated experimentally and numerically, using optical microscopy.

Journal ArticleDOI

Biodegradable Polymers for Biomedical Additive Manufacturing

Dario Puppi,Federica Chiellini +1 more

TL;DR: An update overview of scientific literature on biodegradable polymers for AM application in the biomedical field is provided, highlighting their source of extraction, chemical modification, or synthesis route, and their physical-chemical and processing properties in relationship to AM.

Journal ArticleDOI

Roadmap to 3D-Printed Oral Pharmaceutical Dosage Forms: Feedstock Filament Properties and Characterization for Fused Deposition Modeling.

TL;DR: This commentary reviews recent 3D-printing studies by fused deposition modeling (FDM) technique in pharmaceutical sciences, extending into the fields of polymer processing and rapid prototyping, where more in-depth studies on the feedstock material properties, modeling, and simulation of the FDM process have been performed.

Journal ArticleDOI

Polypropylene Filled With Glass Spheres in Extrusion-Based Additive Manufacturing: Effect of Filler Size and Printing Chamber Temperature

Martin Spoerk,Florian Arbeiter,Ivan Raguž,Georg Weingrill,Thomas Fischinger,Gerhard Traxler,Stephan Schuschnigg,Ludwig Cardon,Clemens Holzer +8 more

TL;DR: In this paper, the incorporation of low aspect ratio fillers improved this issue by successfully decreasing the warpage of 3D-printed polypropylene (PP) parts, which is a promising material for FFF due to its high impact strength, chemical resistance, moisture stability, and low cost.

References

More filters

Journal ArticleDOI

Anisotropic material properties of fused deposition modeling ABS

TL;DR: In this article, the properties of FDM parts fabricated by the FDM 1650 were analyzed using a Design of Experiment (DOE) approach, such as raster orientation, air gap, bead width, color and model temperature.

Journal ArticleDOI

Parametric appraisal of mechanical property of fused deposition modelling processed parts

TL;DR: In this paper, five important process parameters such as layer thickness, orientation, raster angle, Raster width and air gap are considered and their influence on three responses such as tensile, flexural and impact strength of test specimen is studied.

Journal ArticleDOI

Effect of processing conditions on the bonding quality of FDM polymer filaments

TL;DR: In this article, the authors investigated the mechanisms controlling the bond formation among extruded polymer filaments in the fused deposition modeling (FDM) process and showed that the bonding phenomenon is thermally driven and ultimately determines the integrity and mechanical properties of the resultant prototypes.

Book

Rapid Prototyping: Principles and Applications

TL;DR: In this paper, the authors present animated illustrations of the working principles of today's key Rapid prototyping processes, the available models and specifications, and their principles, materials, advantages and disadvantages.