Estimation of filament temperature and adhesion development in fused deposition techniques

TLDR

In this paper, an analytical solution to the transient heat conduction developing during filament deposition in Fused Deposition Techniques (FDT), which is coupled to a routine that activates or deactivates all relevant local boundary conditions depending on part geometry, operating conditions and deposition strategy, is presented.About:

This article is published in Journal of Materials Processing Technology.The article was published on 2017-07-01 and is currently open access. It has received 180 citations till now. The article focuses on the topics: Protein filament & Deposition (phase transition).read more

Figures

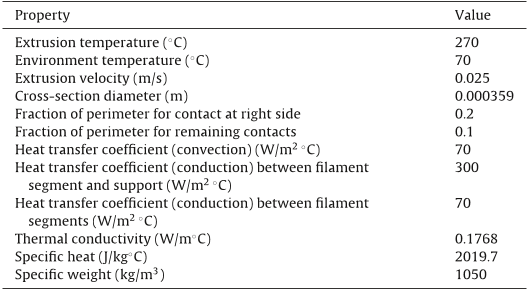

Table 1 Process parameters and material properties.

Table 2 Material properties of ABS FA 4475.

Fig. 5. Geometry and deposition sequence used to illustrate the results of the calculations (dimensions in mm).

Fig. 6 shows the filament temperature at various instants of he deposition process (an animated view of cooling can be creted). Clearly, the newest filament segment or elementary length s always the hottest one and cools down gradually, although the ffect of the physical contacts is difficult to perceive in this repreentation. The phenomenon is better seen in Fig. 7, which depicts he time evolution of the temperature of filament segments 1–9 t a vertical xx plan distant 0.05 m from the origin (see Fig. 5). As a ew filament segment is deposited, the temperature of the adjacent egments increases and so their cooling is delayed. The physical ontacts can alter local filament temperatures by as much as 18 ◦C.

Fig. 15. Temperature evolution with time (at x = 40 mm) of a filament segment deposited on top of another (die set to 200 ◦C and 220 ◦C).

Fig. 7. Time evolution of the temperature of filament segments 1–9 for the geometry and deposition sequence illustrated in Fig. 5, at a vertical xx plan distant 0.05 m from the origin.

Citations

More filters

Journal ArticleDOI

Recent Developments in Fused Deposition Modeling-Based 3D Printing of Polymers and Their Composites

TL;DR: Fused deposition modeling (FDM) is one of the most widely used 3D printing techniques that utilizes polymers to create models, prototypes or even end products as mentioned in this paper, and since 2009, the demand for FD...

Journal ArticleDOI

Process-structure-property effects on ABS bond strength in fused filament fabrication

TL;DR: In this article, the authors measured the tensile strength of interlayer bond lines in ABS coupons printed in two orientations and found that a plateau of 22MPa was observed for a normalized contact length greater than 0.6 independent of print orientation.

Journal ArticleDOI

Design of FDM 3D printed polymers: An experimental-modelling methodology for the prediction of mechanical properties

TL;DR: In this paper, a two-stage thermal and sintering model is developed to predict the bond formation process between filaments in 3D printed polymeric components with custom properties, directly in terms of manufacturing settings.

Journal ArticleDOI

Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament

TL;DR: In this article, the effects of extrusion speed and printing speed on the microstructure and dimensions of an extruded PEEK filament in 3D printing were investigated and a control algorithm that mathematically replaces the nozzle diameter with the diameter of the extruded filament was proposed.

Journal ArticleDOI

Numerical modeling of the strand deposition flow in extrusion-based additive manufacturing

TL;DR: In this paper, the authors proposed a numerical model to simulate the extrusion of a strand of semi-molten material on a moving substrate, within the computation fluid dynamics paradigm, and quantified the effect of the gap distance and the velocity ratio on the size and the shape of the strand.

References

More filters

Journal ArticleDOI

An Optimization Approach for Components Built by Fused Deposition Modeling with Parametric Internal Structures

TL;DR: In this paper, a genetic algorithm-based approach is used to estimate the mechanical properties and calculate the build time and materials utilized based on various internal structural configurations for the component's application.

Thermal Analysis Of Fused Deposition

TL;DR: In this paper, a detailed study of temperature field near the vicinity of deposition point is presented with particular emphasis on dimensional analysis and deposition of multiple material systems, and the impact of liquefier and nozzle design on thermal hardware behavior and operational stability has been quantified.

Book

Differential Equations, Mechanics, and Computation

Richard S. Palais,Robert Palais +1 more

TL;DR: The authors provide a conceptual introduction to the theory of ODEs and numerical methods, focusing on the initial value problem for equations of evolution with applications to the calculus of variations and classical mechanics, along with a discussion of chaos theory and ecological models.

Journal ArticleDOI

A Small‐Scale Experimental Extrusion Set‐Up for Exploring Relationships Between Process‐Induced Structures and Characteristics of Multiphase Polymer Systems

TL;DR: In this article, a small-scale experimental extrusion set-up for sightseeing the morphological evolution during processing and identifying relationships between process-induced structure, blend rheology, and product (extruded sheet) properties is presented.