read more

the shear layer displacement thickness changes from being negative to positive causing the surrounding fluid to be displaced and generating compression waves.

A reference impulse of 1000 kg·m−1·s−1 obtained from impulse measurements at pressure transducer P4 is used to calculate the increment.

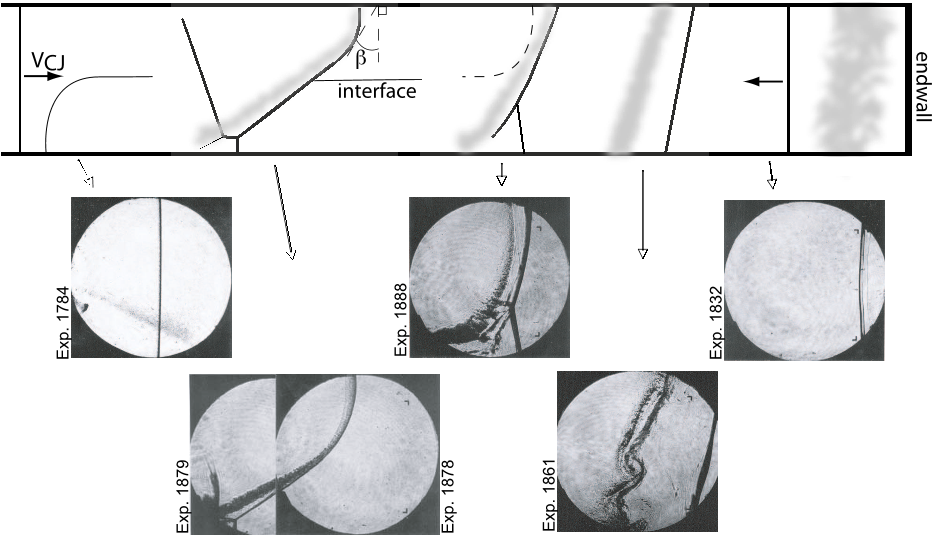

The main consequence of the mixture composition gradient through the diffuse interface was to cause the detonation wave to curve: eventually the reaction zone decouples from the leading shock wave when the combustible mixture becomes sufficiently dilute.

For a detonation modeled as an ideal one-dimensional discontinuity with no affect of curvature on reaction zone structure, the normal component of the curved wave will correspond to the local Chapman-Jouguet detonation velocity.

The sliding valve, actuated by a falling mass, was designed to completely isolate both the combustible mixture and test gas, as well as to open sufficiently fast to control the formation of the gravity current.

The rapid increase in induction time withdecrease in shock velocity results in the decoupling of the reaction zone from the shock and the formation of a gap between the transmitted shock and the turbulent mixing zone.

By using a fuel-rich ethylene-oxygen combustible mixture and an oxidizing test gas, the authors were able to observe and quantify the effects of combustion inside the turbulent mixing zone.

It is evident that the vorticity thickness of the interface is not uniform and exhibits a sinuous shape as a result of the turbulent flow structure present at the interface.

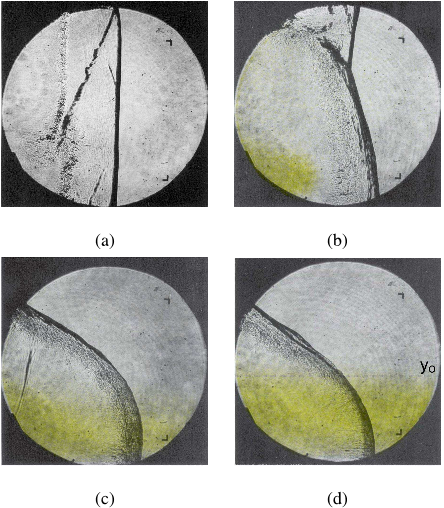

In these experiments the φ = 2.5 ethylene-oxygen combustible mixture is colored yellow for visibility and flows below the less dense nitrogen gas.

When the detonation propagation direction is perpendicular to the mixture gradient, a curved detonation wave results that ultimately decouples into a shock wave and turbulent mixing zone (TMZ), shown in Fig. 1b.

The constant of proportionality C is varied from a value of 1 to 10 to account for interface growth after the shock reflection off the end-wall.

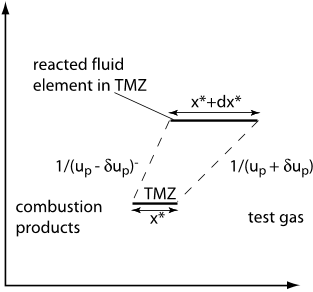

The velocity of the left (δu−p ) and right (δu+p ) edges of the fluid element are combined to obtain an expression for the growth rate of the fluid elementdx∗ dt = δu + p −δu−p .

Visualization for the experiments, using a schlieren system [1], was made through an optical viewport (BK7 or quartz windows) that could be arranged in two separate positions.

The details of this interaction are dependenton the mixture compositions, the relative geometry of the detonation and interface, and the characteristic thickness of the interface.