read more

Efforts are currently underway to investigate this possibility.

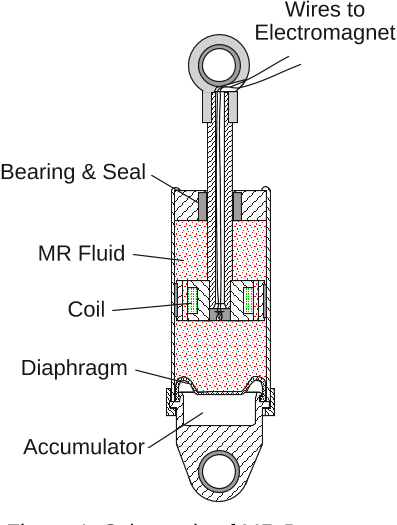

At 0 V the MR damper primarily exhibits the characteristics of a viscous device (i.e., the force-displacement relationship is approximately elliptical, and the force-velocity relationship is nearly linear).

The peak power required is less than 10 watts, which could allow the damper to be operated continuously for more than an hour on a small camera battery.

Semi-active control devices potentially offer the reliability of passive devices, yet maintain the versatility and adaptability of fully active systems.

They offer highly reliable operation at a modest cost and can be viewed as fail-safe in that they become passive dampers should the control hardware malfunction.

To date, active structural control has been successfully applied in over twenty commercial buildings and more than ten bridges (during erection) [20].

Because the MR damper is attached between the first floor and the ground, its displacement is equal to the displacement of the first floor of the structure relative to the ground, i.e., in Eqs. (1–4).

Because the semi-active system has the ability to vary its properties to more effectively control the structure, the clipped optimal controller performed better than both the passive-off and passive-on control systems.

This behavior is primarily due to the time the MR fluid in the damper takes to reach rheological equilibrium and the time lag associated with the dynamics of driving the electromagnet in the MR damper.

The rise time (defined as the time required to go from 10% to 90% of the final value) in the force generated by the MR damper during a constant velocity test when a step in the voltage is applied to the current driver is approximately 8 msec.

If the magnitude of the force produced by the damper is smaller than the magnitude of the desired optimal force and the two forces have the same sign, the voltage applied to the current driver is increased to the maximum level so as to increase the force produced by the damper to match the desired control force.

Various semi-active devices have been proposed which utilize forces generated by surface friction or viscous/viscoelastic-plastic fluids to dissipate vibratory energy in a structural system.

The performance of the semi-active control system employing the MR damper was found to be modestly better in reducing peak displacements than that of the linear active controller, indicating that the semi-active control system is capable of not only approaching, but surpassing, the performance of linear active control system, while only requiring a small fraction of the power that is required by the active controller.

When the MR damper is providing the desired optimal force (i.e., ), the voltage applied to the damper should remain at the present level.

Because accelerometers can readily provide reliable and inexpensive measurement of accelerations at arbitrary points on the structure, development of control methods based on acceleration feedback is an ideal solution to this problem and will be presented subsequently.

The structural measurements used for calculating the desired control force include the absolute accelerations of the three floors of the structure, and the displacement of the MR damper (i.e., ).

According to presently accepted definitions, a semi-active control device is one which cannot input energy into the system being controlled.

Assuming that the forces provided by the MR damper are adequate to keep the response of the primary structure from exiting the linear region, then the equations of motion can be written as(9)ż