General rights

Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright

owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights.

Users may download and print one copy of any publication from the public portal for the purpose of private study or research.

You may not further distribute the material or use it for any profit-making activity or commercial gain

You may freely distribute the URL identifying the publication in the public portal

If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately

and investigate your claim.

Downloaded from orbit.dtu.dk on: Aug 10, 2022

A New Method for Start-up of Isolated Boost Converters Using Magnetic- and Winding-

Integration

Lindberg-Poulsen, Kristian; Ouyang, Ziwei; Sen, Gökhan; Andersen, Michael A. E.

Published in:

Annual IEEE Applied Power Electronics Conference and Exposition

Link to article, DOI:

10.1109/APEC.2012.6165841

Publication date:

2012

Link back to DTU Orbit

Citation (APA):

Lindberg-Poulsen, K., Ouyang, Z., Sen, G., & Andersen, M. A. E. (2012). A New Method for Start-up of Isolated

Boost Converters Using Magnetic- and Winding-Integration. In Annual IEEE Applied Power Electronics

Conference and Exposition: Proceedings (pp. 340-345). IEEE. https://doi.org/10.1109/APEC.2012.6165841

A New Method for Start-up of Isolated Boost

Converters Using Magnetic- and

Winding-Integration

Kristian Lindberg-Poulsen

Technical University of

Denmark, Dept. of

Electrical Engineering

k.lindberg.p@gmail.com

Ziwei Ouyang

Technical University of

Denmark, Dept. of

Electrical Engineering

zo@elektro.dtu.dk

Gökhan Sen

Technical University of

Denmark, Dept. of

Electrical Engineering

gs@elektro.dtu.dk

Michael A.E. Andersen

Technical University of

Denmark, Dept. of

Electrical Engineering

ma@elektro.dtu.dk

Abstract—A new solution to the start-up and low output

voltage operation of isolated boost family converters is presented.

By the use of integrated magnetics and winding integration, the

transformer secondary winding is re-used during start-up as a

flyback winding coupled to the boost inductor. The traditional

added flyback winding coupled to the boost inductor is thus

eliminated from the circuit, bringing substantial cost savings,

increased efficiency and simplified design. Each subinterval of

the converter operation is described through electrical and

magnetic circuit diagrams, and the concept is extended to other

isolated boost family topologies. The principle of operation is

demonstrated with a 800W isolated boost prototype, and a 1600W

primary parallel series secondary isolated boost converter. Effi-

ciency measurements of both prototypes are presented, including

measurements during both start-up and normal boost operation.

I. INTRODUCTION

Isolated boost converters have been shown to be the most

efficient topology for high power, low input voltage, high out-

put voltage applications [1]–[5]. Suitable applications include

distributed generation systems, backup systems, fuel cell con-

verters, electric vehicle applications and avionic applications.

However, a disadvantage of the topology is that the boost

characteristic sets a lower limit for the output voltage, which

introduces in-rush current during start-up from zero output

voltage, as well as during fault situations such as output short

circuit.

Fig.1 shows a common solution to the start-up problem [6],

[7]. A flyback winding is arranged on the boost inductor, such

Fig. 1. Isolated full-bridge boost converter with traditional start-up method

using added external flyback winding and diode.

that the converter may operate as a flyback converter during

start-up with the associated buck-boost voltage modulation

factor allowing control of the output voltage all the way down

to zero volts. During normal boost operation, the flyback wind-

ing is completely inactive, but occupies part of the winding

window of the boost inductor, leaving less copper area for the

boost inductor, which in turn causes a drop in efficiency. Being

a power transferring magnetic component, the flyback winding

is a relatively expensive circuit element and complicates the

assembly of the boost inductor. Fig.2 and Fig.3 respectively

show the simplified and complete circuit diagrams of the new

circuit topology, where the magnetic integration of the boost

inductor with the transformer allows the boost inductor to

couple to the secondary winding during start-up, such that

the secondary winding acts as flyback winding.

II. PRINCIPLE OF OPERATION

Figures 4 to 7 explain the principle of operation as

applied to the basic full-bridge isolated boost topology. Each

Fig. 2. Electrical circuit diagram of new start-up method.

Fig. 3. Electrical and magnetic circuit diagram of new start-up method using

EI core with center leg air gap.

978-1-4577-1216-6/12/$26.00 ©2012 IEEE 340

subinterval of operation is shown with an electric circuit

diagram followed by the corresponding and a magnetic core

diagram. Relevant voltage polarities are marked with +/-

signs, and current directions are marked with arrows while

inactive elements are dimmed. The electric circuit diagrams

correspond to their respective core diagrams by the ports

marked a, b, c, d. The core diagrams include the flux rate,

dφ

dt

= φ

0

, induced by the inductor, as well as the flux rate

induced by the transformer. The circuit operation can be

understood by analysing voltage polarities and flux rates

together with the right hand rule, while taking into account

the switch states, current directions and diode bias.

Boost mode operation (D

sw

≥ 0.5)

In the familiar isolated boost topology, the full-bridge

switch duty cycle must be above 0.5, such that there is always

a current path available for the boost inductor. This is defined

as the normal boost mode operation. The gate signal is

phase-shifted 180

◦

between each diagonal high-side/low-side

switch pair. Since D

sw

≥ 0.5, the phase shifted gate signals

overlap such that either all switches are on, or two diagonal

switches are on.

When all switches are on, V

in

is applied to the boost inductor,

and the input current is increasing. Known as the charging

or boosting subinterval, the circuit operation during this is

shown in fig. 4. As seen in fig. 4(b), the flux rate induced by

the inductor is uncoupled from the transformer windings due

to the fact that the voltage drops induced on the transformer

windings on each side leg are of opposite polarity.

The second sub-interval, referred to as the boost mode

discharge subinterval, is shown in fig. 5. When two diagonal

switches are on and the other two are off, the inductor

current passes through the primary winding, allowing the

corresponding diagonal diode pair of the output rectifier to

become forward biased. The output voltage is reflected to the

primary winding, such that a negative voltage drop is applied

over the inductor, decreasing the current. The corresponding

core diagram in fig. 5(b) shows that the inductor flux rate

is decreasing, and is still uncoupled from the transformer.

Additionally, it is noted that the flyback diode D

f

is reverse

biased.

Start-up mode operation (D

sw

< 0.5)

When the switch duty cycle is reduced below 0.5, the

diagonal switch pairs are no longer overlapping in on-state,

meaning that either two diagonal switches are on or all

switches are off. When two switches are on, the circuit

operation is identical to the boost mode discharge subinterval,

except that the inductor current is now decreasing due to the

fact that the primary voltage is lower than the input voltage,

causing a positive voltage drop over L. Because of this,

the subinterval is referred to as the start-up mode charging

subinterval, and the corresponding circuit and core diagrams

are seen in fig. 6.

(a) Boost mode, charging subinterval, circuit diagram.

(b) Boost mode, charging subinterval, core diagram.

Fig. 4. Boost mode, charging subinterval. All switches are on, inductor

current is increasing. Core diagram shows that inductor flux rate is decoupled

from transformer.

(a) Boost mode, discharging subinterval, circuit diagram.

(b) Boost mode, discharging subinterval, core diagram.

Fig. 5. Boost mode, discharge subinterval. Two diagonal switches are on,

inductor current is decreased by transferring energy through the transformer.

It is noted that D

f

is reverse biased..

When all switches are off, there needs to be an alternative

current path such that the inductor flux remains continuous

in order to avoid MOSFET avalanche mode clamping of the

stored energy. This current path is provided by the secondary

transformer winding, which thereby acts as a flyback winding

during the flyback discharge subinterval seen in fig. 7. During

switch turn off, the inductor current is decreasing, creating a

341

(a) Startup mode, charging subinterval, circuit diagram.

(b) Startup mode, charging subinterval, core diagram.

Fig. 6. Start-up mode, charging subinterval. Two diagonal switches are on,

charging the inductor while also transferring energy through the transformer.

reverse in the flux rate, as seen by comparing φ

0

L

on fig. 6(b)

and fig. 7(b). Following the right hand rule, it is evident that

this induces respective voltage drops over each half of the

secondary winding, with polarities such as to allow D

f

to

become forward biased. The two halves of the secondary

winding will then be working in parallel to discharge the

energy stored in the air gap, with the full output voltage

applied to each winding half.

It should be noted that it would also be possible to run the

converter in "pure flyback mode", wherein either all switches

are on or all switches are off. However, this means that

zero energy is transferred to the output during the boosting

subinterval, leading to higher current ripple at same output

power. The "hybrid" startup mode shown in figs. 6 and 7 has

been described in-depth as applied to a conventional external

flyback winding [7], and the specific timing analysis of the

previous work can be directly applied to the new integrated

magnetic approach.

III. EXTENSION TO OTHER ISOLATED BOOST FAMILY

TOPOLOGIES

The concept can readily be applied to numerous isolated

boost derived topologies, such as flyback- current-fed push-

pull [8], dual inductor [9], and parallel primary isolated boost

[3]. It can also be applied to various rectification circuits,

including voltage doubler and center tap rectifier. Figure 8

shows the principle applied to an isolated boost converter with

a center tap rectifier. In this case, the flyback diode D

f

is no

longer required, and the start-up functionality is gained "or

free" using only the specified integrated magnetic structure,

which may be beneficial in itself by reducing magnetic com-

(a) Startup mode, discharging subinterval, circuit diagram.

(b) Startup mode, discharging subinterval, core diagram.

Fig. 7. Start-up mode, flyback discharge subinterval. All switches are turned

off. The drop in inductor current causes a reverse in the associated flux rate,

which couples to the secondary transformer windings. From the polarity of

the induced voltages, it is evident that this allows D

f

to be forward biased,

such that the energy stored in the air gap can be discharged to the converter

output.

Fig. 8. New start-up method applied to isolated boost with center tap

rectification circuit, where a flyback diode is not required.

ponent count and increasing efficiency [10]. Figure 9 shows

the principle applied to the parallel primary topology, which

has been shown to be an efficient way of scaling isolated boost

converter design for higher power [3], [4]. Additionally, the

shown implementation features a shared center leg for flux

cancellation, resulting in increased efficiency [11]. It is noted

that only a single flyback diode is required, regardless of the

degree of paralleling.

Additional applications include dual inductor isolated boost

and Weinberg/push-pull isolated boost topologies.

IV. EXPERIMENTAL VERIFICATION

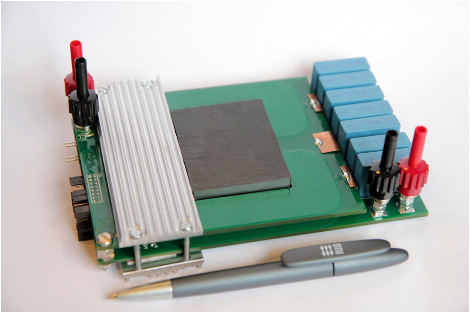

An 800W isolated boost prototype as well as a 1600W

parallel primary isolated boost prototype have been built

in order to verify the start-up functionality, as well as to

demonstrate the possibility of achieving high efficiency and

high power density by application of the integration method.

Both converters are hard-switched, and rely on extensive

interleaving to achieve a low transformer leakage inductance

342

Fig. 9. New start-up method applied to parallel primary isolated boost

topology.

of 91nH and 124nH respectively. The converters are designed

for fuel-cell application, where a fuel cell output voltage of

25-35V is expected.

Figure 11 shows current measurements during start-up mode

of the isolated boost prototype. The converter is running at

V

in

= 25V , D

sw

= 40%, V

out

= 60V and 100Ω load. C3

(blue) shows the AC component of the input current, C4(green)

shows the AC component of the current through a high side

output rectifier D

1

, while C1(yellow) and C2(red) show the

two gate signals.

When the gate signal C1(yellow) is high, D

1

and D

3

are

forward biased, conducting a constant current through the

secondary winding to the load. During this period, the boost

inductor current C3(blue) is rising. After C1(yellow) goes to

zero, all MOSFETs are turned off, and the boost inductor

current quickly drops. At this moment, current continues

flowing through D

1

, safely discharging the energy stored in

the boost inductor to the output. In fig. 11, C4(green) shows

the current of the flyback diode D

f

, clearly demonstrating the

commutation of the boost inductor current.

Fig. 10. Currrent waveforms of isolated boost prototype during startup mode.

C3 (blue) shows the AC component of the input current, C4(green) shows the

current through a high side output rectifier D

1

, while C1(yellow) and C2(red)

show the two gate signals.

Fig. 11. Currrent waveforms of isolated boost prototype during startup mode.

C3 (blue) shows the AC component of the input current, C4(green) shows the

current through the flyback diode D

f

, while C1(yellow) and C2(red) show

the two gate signals.

A. Efficiency Measurements

In order to measure the efficiency during start-up of the par-

allel primary prototype, the duty-cycle was gradually increased

from zero to 74%. A fixed load of 100Ω is used across the

range, corresponding to the rated 1600W at V

out

= 400V .

Figure 12 shows the resulting efficiency measurements, as

well as the measured output voltage at each duty cycle. The

local maximum of efficiency around D

sw

= 20% is caused

by discontinuous conduction mode. Close to D

sw

= 50%, the

efficiency rises dramatically, as an increasingly greater propor-

tion of the total power is transferred through the transformer

rather than the flyback operation. The converter is capable of

operating continuously in start-up mode without overheating,

and the voltage transitions smoothly across D

sw

= 50%.

The efficiency during normal operation was measured for

both the 800W isolated boost prototype and the 1600W

parallel primary. Figure 13 shows the isolated boost prototype

measurements, while fig. 12 shows the results for the parallel

primary prototype. Both prototypes have a peak efficiency

Fig. 12. Efficiency measurements of parallel primary prototype, showing

efficiency and output voltage as a function of duty cycle, with a fixed load

of 100Ω.

343