A novel strategy to enhance interfacial adhesion in fiber-reinforced calcium phosphate cement

TLDR

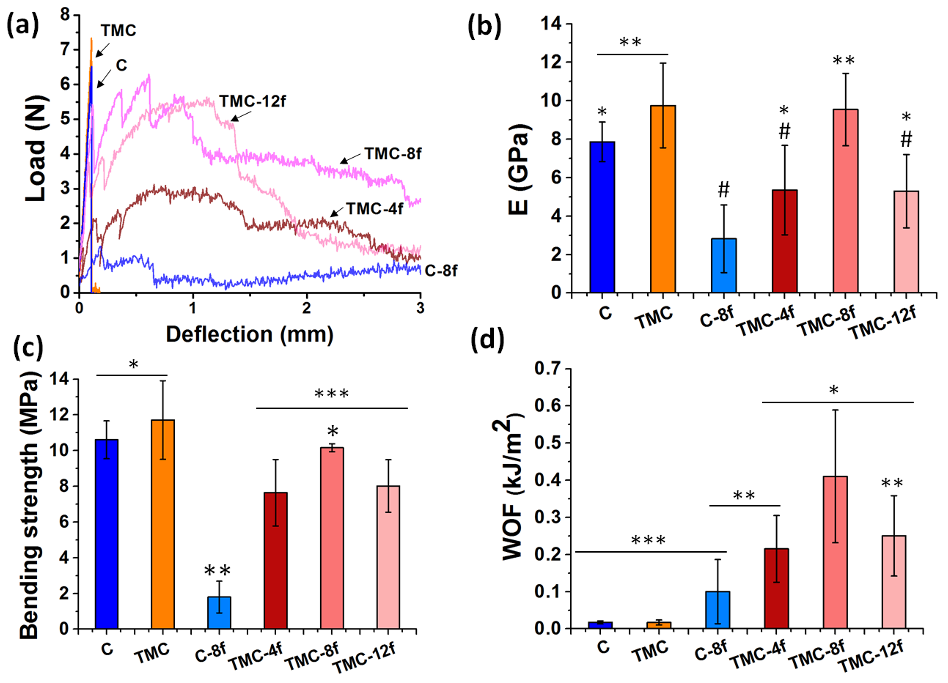

The aim of the present work was to improve the interfacial adhesion between fibers and matrix to obtain tougher biocompatible fiber-reinforced calcium phosphate cements (FRCPCs), which resulted in an increase of the work of fracture (several hundred-fold increase), while the elastic modulus and bending strength were maintained similar to the materials without additives.Abstract:

Calcium phosphate cements (CPCs) are extensively used as synthetic bone grafts, but their poor toughness limits their use to non-load-bearing applications. Reinforcement through introduction of fibers and yarns has been evaluated in various studies but always resulted in a decrease in elastic modulus or bending strength when compared to the CPC matrix. The aim of the present work was to improve the interfacial adhesion between fibers and matrix to obtain tougher biocompatible fiber-reinforced calcium phosphate cements (FRCPCs). This was done by adding a polymer solution to the matrix, with chemical affinity to the reinforcing chitosan fibers, namely trimethyl chitosan (TMC). The improved wettability and chemical affinity of the chitosan fibers with the TMC in the liquid phase led to an enhancement of the interfacial adhesion. This resulted in an increase of the work of fracture (several hundred-fold increase), while the elastic modulus and bending strength were maintained similar to the materials without additives. Additionally the TMC-modified CPCs showed suitable biocompatibility with an osteoblastic cell line.read more

Figures

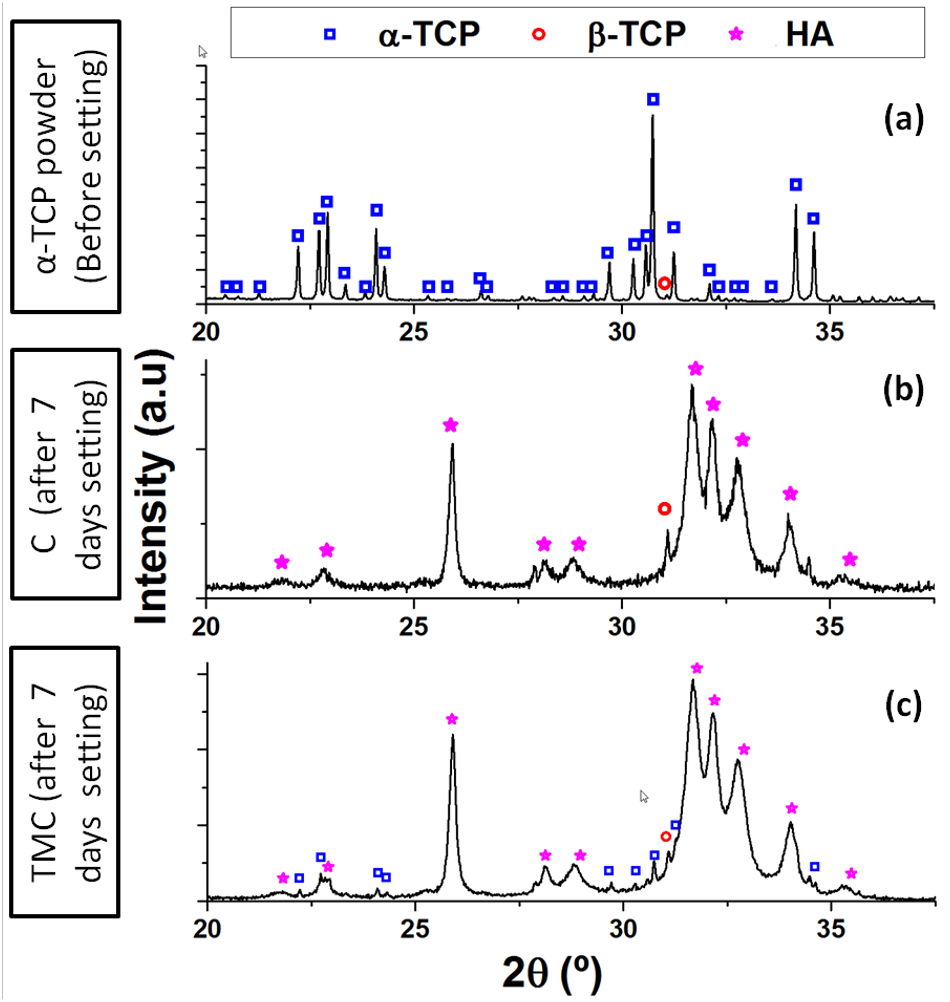

Figure 2. Crystalline phases determined by X-ray diffraction of a) initial powder α –TCP, b) sample C 7 days after setting, and c) sample TMC 7 days after setting.

Figure 3. Mechanical properties under bending of unreinforced CPCs (C and TMC) and fiberreinforced CPCs (C-8f, TMC-4f, TMC-8f, TMC-12f): a) Typical load/deflection curves, b) Young’s modulus (E), c) bending strength, and d) work of fracture (WOF). Groups indicated with same symbol do not have statistically significant differences (p > 0.05).

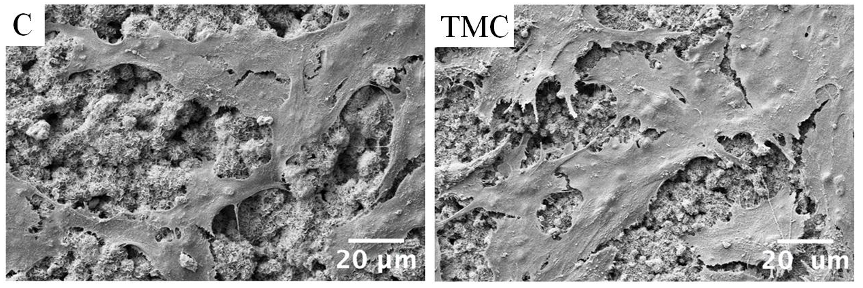

Figure 7. SEM images showing the morphology of cells cultured on C and TMC samples for 7 days.

Figure 6. Live/dead images showing the alive cells (green) and the dead cells (red) on the C and TMC samples surface at different time points (bar = 100 μm)

Figure 5. a) Number of cells adhered on the samples surface at different time points, and b) evolution with time of the pH of the cell culture medium (1 ml) in contact with a cement disc (15 mm diameter x 1.5 mm thickness).

Table 3. Crystalline phases as determined by X-ray diffraction, and specific surface area measured by N2 adsorption of the initial powder and set cements.

Citations

More filters

Journal ArticleDOI

Bone biomaterials and interactions with stem cells.

TL;DR: A comprehensive review of the state of the art of bone biomaterials and their interactions with stem cells is presented and the promising seed stem cells for bone repair are summarized, and their interaction mechanisms are discussed in detail.

Journal ArticleDOI

Bioceramics and bone healing.

TL;DR: Advanced technologies open up new possibilities in the design of bioceramics for bone regeneration; 3D-printing technologies, in combination with the development of hybrid materials with enhanced mechanical properties, supported by finite element modelling tools are expected to enable the design and fabrication of mechanically competent patient-specific bone grafts.

Book ChapterDOI

Synthetic bone graft substitutes: Calcium-based biomaterials

TL;DR: In this paper, the main characteristics and the potential of synthetic bone graft substitutes based on calcium for dental applications are described, and the current and novel strategies based on ion doping, surface functionalization, and additive manufacturing are discussed.

Journal ArticleDOI

Reinforcement and Fatigue of a Bioinspired Mineral–Organic Bioresorbable Bone Adhesive

TL;DR: Biological and biomechanical performance of the fiber‐reinforced adhesive is evaluated in a rabbit distal femur osteotomy model, showing the potential of the bone adhesive for clinical use.

Journal ArticleDOI

Toward stronger robocast calcium phosphate scaffolds for bone tissue engineering: A mini-review and meta-analysis

TL;DR: In this article , the current state of knowledge and existing research on robocasting of calcium phosphate scaffolds are presented, and a meta-analysis from the published literature of the compressive strength of the robocast calcium-phosphate scaffolds is provided.

References

More filters

Journal ArticleDOI

Quantitative interpretation of X-ray diffraction patterns of mixtures. II. Adiabatic principle of X-ray diffraction analysis of mixtures

TL;DR: In this article, the matrix-flushing theory and the adiabatic principle were applied in applied X-ray diffraction analysis to obtain the quantitative composition of a mixture.

Journal ArticleDOI

The mechanical properties of bone tissue in children.

John D. Currey,G Butler +1 more

TL;DR: Compared with the bone of adults, that of children had a lower modulus of elasticity, a lower bending strength, and a lower ash content, but the children's bone deflected more and absorbed more energy before breaking.

Journal ArticleDOI

A Biopolymer Chitosan and Its Derivatives as Promising Antimicrobial Agents against Plant Pathogens and Their Applications in Crop Protection

TL;DR: In this paper, the authors present an overview of the antimicrobial effects, mechanisms, and applications of a biopolymer chitosan and its derivatives in crop protection, and take a closer look at the physiochemical properties and chemical modifications of chitosa molecule.

Journal ArticleDOI

New method for the quaternization of chitosan

TL;DR: In this article, the role of sodium iodide as an electrostatic charges screening salt is discussed, and the reaction was performed in several steps to obtain derivatives of chitosan at various degrees of quaternization with a limit value near 64%.

Journal ArticleDOI

Injectable and macroporous calcium phosphate cement scaffold.

TL;DR: The injectability of a ceramic scaffold, a macroporous CPC, was studies for the first time and may be useful in surgical sites that are not freely accessible by open surgery or when using minimally invasive techniques.

Related Papers (5)

Reinforcement Strategies for Load-Bearing Calcium Phosphate Biocements

Fiber reinforced calcium phosphate cements -- on the way to degradable load bearing bone substitutes?

Reinhard Krüger,Jürgen Groll +1 more