University of Central Florida University of Central Florida

STARS STARS

Faculty Bibliography 2010s Faculty Bibliography

1-1-2010

Directed assembly of solution processed single-walled carbon Directed assembly of solution processed single-walled carbon

nanotubes via dielectrophoresis: From aligned array to individual nanotubes via dielectrophoresis: From aligned array to individual

nanotube devices nanotube devices

Paul Stokes

University of Central Florida

Saiful I. Khondaker

University of Central Florida

Find similar works at: https://stars.library.ucf.edu/facultybib2010

University of Central Florida Libraries http://library.ucf.edu

This Article is brought to you for free and open access by the Faculty Bibliography at STARS. It has been accepted for

inclusion in Faculty Bibliography 2010s by an authorized administrator of STARS. For more information, please

contact STARS@ucf.edu.

Recommended Citation Recommended Citation

Stokes, Paul and Khondaker, Saiful I., "Directed assembly of solution processed single-walled carbon

nanotubes via dielectrophoresis: From aligned array to individual nanotube devices" (2010).

Faculty

Bibliography 2010s

. 828.

https://stars.library.ucf.edu/facultybib2010/828

Directed assembly of solution processed single-walled carbon nanotubes via

dielectrophoresis: From aligned array to individual nanotube devices

Paul Stokes, and Saiful I. Khondaker

Citation: Journal of Vacuum Science & Technology B 28, C6B7 (2010); doi: 10.1116/1.3501347

View online: https://doi.org/10.1116/1.3501347

View Table of Contents: https://avs.scitation.org/toc/jvb/28/6

Published by the American Vacuum Society

ARTICLES YOU MAY BE INTERESTED IN

High quality solution processed carbon nanotube transistors assembled by dielectrophoresis

Applied Physics Letters 96, 083110 (2010); https://doi.org/10.1063/1.3327521

Solution processed large area field effect transistors from dielectrophoreticly aligned arrays of carbon nanotubes

Applied Physics Letters 94, 113104 (2009); https://doi.org/10.1063/1.3100197

Single- and multi-wall carbon nanotube field-effect transistors

Applied Physics Letters 73, 2447 (1998); https://doi.org/10.1063/1.122477

Low voltage, high performance inkjet printed carbon nanotube transistors with solution processed ZrO

2

gate

insulator

Applied Physics Letters 103, 082119 (2013); https://doi.org/10.1063/1.4819465

The work function of the elements and its periodicity

Journal of Applied Physics 48, 4729 (1977); https://doi.org/10.1063/1.323539

Well-aligned and suspended single-walled carbon nanotube film: Directed self-assembly, patterning, and

characterization

Applied Physics Letters 94, 261903 (2009); https://doi.org/10.1063/1.3151850

Directed assembly of solution processed single-walled carbon nanotubes

via dielectrophoresis: From aligned array to individual nanotube

devices

Paul Stokes and Saiful I. Khondaker

a兲

Nanoscience Technology Center and Department of Physics, University of Central Florida, 12424 Research

Parkway, Orlando, Florida 32826

共Received 9 July 2010; accepted 7 September 2010; published 29 November 2010兲

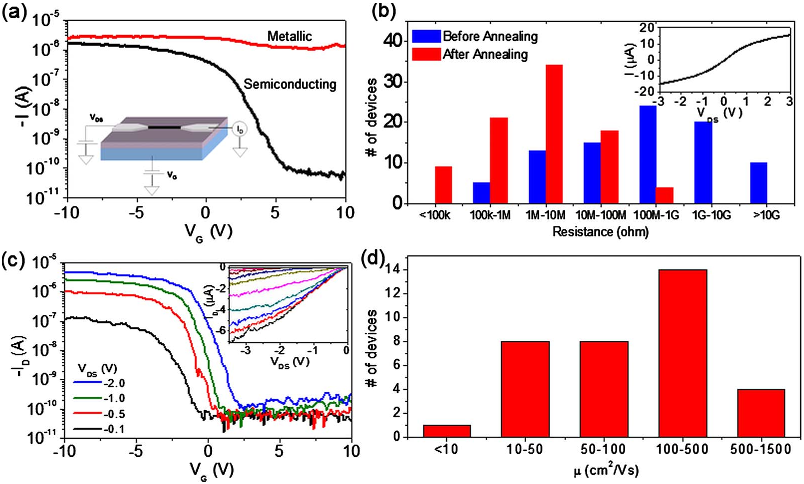

The authors demonstrate directed assembly of high quality solution processed single-walled carbon

nanotube 共SWNT兲 devices via ac dielectrophoresis using commercially available SWNT solutions.

By controlling the shape of the electrodes, concentration of the solution, and assembly time, the

authors are able to control the assembly of SWNTs from dense arrays down to individual SWNT

devices. Electronic transport studies of individual SWNT devices show field effect mobilities of up

to 1380 cm

2

/ V s for semiconducting SWNTs and saturation currents of up to ⬃15

A for metallic

SWNTs. The field effect mobilities are more than an order of magnitude improvement over previous

solution processed individual SWNT devices and close to the theoretical limit. Field effect

transistors 共FET兲 fabricated from aligned two-dimensional arrays of SWNT show field effect

mobility as high as 123 cm

2

/ V s, which is three orders of magnitude higher than the solution

processed organic FET devices. This study shows promise for commercially available SWNT

solution for the parallel fabrication of high quality nanoelectronic devices. © 2010 American

Vacuum Society. 关DOI: 10.1116/1.3501347兴

I. INTRODUCTION

The unique electronic properties of single-walled carbon

nanotubes 共SWNTs兲 make them promising candidates for fu-

ture nanoelectronic devices.

1

For practical applications in na-

noelectronics, it is important that SWNTs are assembled at

selected positions of the circuit with high yield. Chemical

vapor deposition 共CVD兲 growth of SWNTs using litho-

graphically patterned catalytic islands and then making elec-

trical contact to them has been used for the parallel fabrica-

tion of SWNT devices.

2,3

Although CVD grown SWNT has

shown good device properties, high growth temperature

共900 °C兲 is a major bottleneck to make them compatible

with current complementary metal-oxide-semiconductor

共CMOS兲 fabrication technologies.

An attractive alternative to CVD growth techniques for

the high throughput assembly of SWNT electronic devices at

selected positions of the circuit is from postsynthesis fabri-

cation using solution processed SWNTs.

4

Solution process-

ing could be advantageous due to its ease of processing at

room temperature, CMOS compatibility, and potential for

scaled up manufacturing of SWNT devices on various sub-

strates. Several assembly techniques from solution include

chemical and biological patterning,

5,6

flow assisted

alignment,

7

Langmuir–Blodgett assembly,

8

bubble blown

films,

9

contact printing,

10

spin coating assisted alignment,

11

and evaporation driven self-assembly.

12

However, most of

these techniques are used either for only large area devices or

only single nanotube devices. In addition, most of these as-

sembly techniques require postetching to remove excess

SWNTs in the circuit.

Dielectrophoresis 共DEP兲 offers a convenient way in which

SWNTs can be precisely positioned from solution at room

temperature using a nonuniform ac electric field on prepat-

terned electrodes.

13–24

DEP can be advantageous over other

solution processed techniques because it allows for the posi-

tioning from large areas to individual SWNTs at predefined

coordinates of the circuit and does not require the need of

postetching or transfer printing. One crucial aspect of the

DEP process is the quality of the SWNT solution. The solu-

tion should be free of catalytic particles, contain mostly in-

dividual SWNTs, and be stable for long periods of time.

Catalytic particles in the solution tend to make their way into

the electrode gap with the SWNTs during assembly process

due to their highly conducive nature which can disrupt their

device performance. Solutions containing bundles make it

difficult to only obtain individual SWNTs reproducibly into

the electrode gap as the DEP force will likely select the

larger bundles due to their higher dielectric constant and con-

ductivity. Additionally, avoiding degradation of the SWNTs

from processing is extremely important to maintain their ex-

cellent electrical properties.

25

In this article, we used a clean commercially available,

surfactant-free SWNT solution combined with the DEP tech-

nique to achieve directed assembly of high quality SWNT

devices with high yield. By optimizing the device design,

concentration of the solution, and assembly time, we are able

to control the assembly of SWNTs from large scale arrays

down to individual devices. Comparison of the assembly

from commercial solution of SWNT with other homemade

solutions in common organic solvents show that the clean

a兲

Author to whom correspondence should be addressed; electronic mail:

saiful@mail.ucf.edu

C6B7 C6B7J. Vac. Sci. Technol. B 28„6…, Nov/Dec 2010 1071-1023/2010/28„6…/C6B7/6/$30.00 ©2010 American Vacuum Society

assembly was obtained from the commercial solution. Elec-

tronic transport properties of individual semiconducting

SWNTs show field effect mobilities up to 1380 cm

2

/ V s and

saturation currents up to ⬃15

A for metallic SWNTs. The

field effect mobilities are more than an order of magnitude

improvement over previous solution processed individual

SWNT devices and close to the theoretical limit. Addition-

ally, field effect transistors 共FET兲 fabricated from aligned

two-dimensional 共2D兲 arrays of SWNT show field effect mo-

bilities as high as 123 cm

2

/ V s, which is three orders of

magnitude higher than solution processed organic FET de-

vices.

II. EXPERIMENTAL DETAILS

A. Electrode design and fabrication

Devices were fabricated on heavily doped silicon sub-

strates capped with a thermally grown 250 nm thick SiO

2

layer. The electrode patterns were fabricated by a combina-

tion of optical and electron beam lithography 共EBL兲. First,

contact pads and electron beam markers were fabricated with

optical lithography using double layer resists 共LOR 3A/

Shipley 1813兲 developing in CD26, thermal evaporation of 3

nm Cr and 50 nm Au followed by lift-off. Smaller electrode

patterns were fabricated with EBL using single layer PMMA

resists and then developing in 共1:3兲 methyl isobutyl keto-

ne:isopropal alchohol 共MIBK:IPA兲. After defining the pat-

terns, 2 nm Cr and 25 nm thick Pd were deposited using

electron beam deposition followed by lift-off in warm ac-

etone. Pd was used because it is known to make the best

electrical contact to SWNTs.

3

Figures 1共a兲 and 1共b兲 show a

cartoon of the electrode patterns for the DEP assembly of

individual SWNTs and parallel arrays of SWNTs, respec-

tively. The electrode patterns for the alignment of individual

tubes use a pair of adjacent taper shaped electrodes with

sharp tips separated by 1

m, whereas the electrode patters

for aligned arrays of SWNTs were done using 200

m long

parallel electrodes with 5

m spacing.

B. Solution preparation

We used three different SWNT solutions for the DEP as-

sembly: 共i兲 A homemade dimethylformamide 共DFM兲 solu-

tion, 共ii兲 homemade dichloroethane 共DCE兲 solution, and 共iii兲

already suspended, surfactant-free aqueous SWNT solution

purchased from Brewer Science Inc.

26

The DMF-SWNT sus-

pension was made by ultrasonically dispersing HiPCO

grown SWNTs 共Carbon Nanotechnologies Inc.兲 in ⬃5ml

DMF and 1 ml trifluoroacetic acid 共TFA兲. TFA was used to

dissolve any unwanted catalytic particles and amorphous car-

bon from the bulk material. After dissolving the SWNTs in

DMF/TFA, the solution was centrifuged, the supernatant was

decanted, and the solid is then redispersed for further

dispersion/centrifugation/decantation cycles. The final solu-

tion was diluted until it became clear and then sonicated for

several minutes before assembly. The DCE mixture was

made by simply adding a very small pinch of the HiPCO

SWNT soot to ⬃4 ml of DCE and then sonicating for

⬃5 – 10 min before the assembly. The commercial solution

has an original SWNT concentration of ⬃50

g/ ml and was

diluted using de-ionized 共DI兲 water to a desired concentra-

tion.

C. Dielectrophoretic assembly

The directed assembly of SWNTs at predefined electrode

positions was done in a probe station under ambient condi-

tions. A small drop of SWNT solution was cast onto the chip

containing the electrode pairs. An ac voltage of 1 MHz,

5V

p-p

was applied using a function generator between the

source and drain electrodes or by a simultaneous deposition

technique

14,22

共between source and gate兲 to align at several

electrode pairs simultaneously. The ac voltage gives rise to a

time averaged dielectrophoretic force. For an elongated ob-

ject, it is given by F

DEP

⬀

m

Re关K

f

兴ⵜE

rms

2

, K

f

=共

p

ⴱ

−

m

ⴱ

兲/

m

ⴱ

,

and

p,m

ⴱ

=

p,m

−i共

p,m

/

兲, where

p

and

m

are the permit-

tivities of the nanotube and, solvent respectively, K

f

is the

Claussius–Mossotti factor,

is the conductivity, and

=2

f is the frequency of the applied ac voltage.

27

The in-

duced dipole moment of the nanotube interacting with the

strong electric field causes the nanotubes to move in a trans-

lational motion along the electric field gradient.

Figures 1共c兲 and 1共d兲 show a simulation of the electric

field around the electrode gap for the adjacent taper shaped

electrode and parallel plate electrode, respectively. The simu-

lations were done using a commercially available software

共

FLEX PDE兲 assuming that the potential phasor is real and

therefore using the electrostatic form of the Laplace equation

共ⵜ

2

⌽=0兲.

14

Hence we can set the effective potential of the

electrodes to ⌽ = ⫾V

p-p

/ 2 for our simulation. From Fig.

1共c兲, it can be seen that the strongest electric field lines are

confined at the sharp tips. This increases the probability of

aligning individual SWNTs. For the parallel plate geometry,

the electric field is uniform throughout the electrode gap al-

lowing for many nanotubes to align parallel to one another

throughout the gap. After the assembly, the function genera-

FIG.1. 共Color online兲共a兲 Cartoon of the electrode patterns for DEP assem-

bly of 共a兲 individual SWNTs and 共b兲 2D arrays of SWNTs. 2D simulated

electric field around the electrode gap for 共c兲 the taper shaped electrodes and

共d兲 parallel plate electrodes.

C6B8 Paul Stokes and Saiful I. Khondaker: Directed assembly of solution processed SWNTs C6B8

J. Vac. Sci. Technol. B, Vol. 28, No. 6, Nov/Dec 2010

tor was turned off and the sample was blown dry by a stream

of nitrogen gas.

III. RESULTS AND DISCUSSIONS

A. Controlling the assembly of individual SWNTs

Figure 2 shows the effect of SWNT concentration on the

DEP assembly using the commercial solution diluted in DI

water. We use a simultaneous deposition technique

14,22

in

this case, applying the ac field between source and gate for 3

min. Figure 2共a兲 shows an atomic force microscopy 共AFM兲

image of a device after the assembly for a SWNT concentra-

tion of 1000 ng/ml. Dilution of the solution by ten times to

100 ng/ml concentration yield less SWNTs in the gap, as

shown in Fig. 2共b兲. It can be seen here in both cases that the

SWNTs mimic the electric field lines around the electrode

gap, as simulated in Fig. 1共c兲. The yield for the 1000 ng/ml

and 100 ng/ml concentration is ⬎95%. By diluting the solu-

tion to 10 ng/ml, we obtained an individual SWNT in the gap

关Fig. 2共c兲兴. The diameter of this individual SWNT is

⬃2.0 nm, measured by AFM. Figure 2共d兲 shows a histogram

of ⬃100 individual SWNTs giving an average diameter of

2.0⫾0.2 nm. Approximately 10% of the diameters are

greater than 3.5 nm, which is an indication of the possible

presence of some double-walled nanotubes or large diameter

SWNTs.

28

The total yield of individual SWNTs at low con-

centration is ⬃20% on average and as high as 35% for a

single chip. Figure 3 shows a number of SEM images of

individual nanotubes assembled by this technique. It can be

seen here that the devices are free of bundles and catalytic

particles which stems from the quality of the commercial

solution.

B. Comparison of solutions

We investigated the effect of the different solutions at low

concentration 共⬃10 ng/ ml兲 on the DEP assembly. In con-

trast to the commercial solution in water, for the DMF and

DCE solutions, we apply the ac voltage between one pair at

a time for ⬃5 s. This is done because long trapping times

are more complex to use as DMF and DCE evaporate

quickly in air. Figure 4共a兲 shows a representative AFM im-

age after the assembly for the DMF solution. As can be

clearly seen here, the resulting SWNT deposition contains a

bundle and catalytic particles shown by the arrows. At cer-

tain areas along the SWNT, the diameter is as large as 30–40

nm. Figure 4共b兲 shows the representative AFM image of a

device after assembling the SWNTs using DCE. The result-

ing device also contains catalytic particles near the electrode

tip on the right and shows diameters up to 10 nm along the

SWNT. Figure 4共c兲 shows an AFM image of a device after

assembly by using the Brewer Science SWNT solution. It is

clear from the AFM image that the SWNT is individual and

does not contain any catalytic particles. The commercial so-

lution turned out to be stable for months, therefore increasing

the reproducibility. For the DCE solution we were able to

assemble ⬃10 individual SWNT devices out of ⬃80 tries,

however, all of them contained catalytic particles 共with

diameter⬎10 nm兲 attached to the tubes. Another problem

that arises when using DCE is that it evaporates in air very

quickly, it is highly toxic, volatile, and did not remain stable

for more than a few hours. In the DMF case, the solutions

also only remained stable for a short period of time and the

results often came with larger diameter bundles ⬎15 nm out

of ⬃50 tries.

As can be concluded here, the commercial solution

yielded the best results for the assembly of clean and indi-

vidual SWNT devices. The good results from the commercial

solution are due to several reasons. First, its very low density

of impurity particles 共less than 50 ppb兲

26

is particularly ad-

vantageous in the DEP process because catalytic particles in

the solution tend to make their way into the electrode gap

during DEP due to their high conductivity. This is displayed

FIG.2. 共Color online兲 AFM image of nanotubes assembled between the

electrodes with SWNT concentrations of 共a兲 1000 ng/ml 共b兲 100 ng/ml, and

共c兲 10 ng/ml in the solution. Scale bar: 1

m in all images. 共d兲 Histogram of

diameters for over 100 nanotube devices.

FIG.3. 关共a兲-共l兲兴 SEMs of several individual SWNT assembled via DEP from

commercial solution at a concentration of ⬃10 ng/ml. Gap between the

electrodes is 1

m.

FIG.4. 共Color online兲 Representative AFM images of SWNTs assembled via

DEP 共a兲 from DMF solution, 共b兲 from DCE solution, and 共c兲 the Brewer

Science solution.

C6B9 Paul Stokes and Saiful I. Khondaker: Directed assembly of solution processed SWNTs C6B9

JVSTB-MicroelectronicsandNanometer Structures