A numerical approach for the study of glass furnace regenerators

TLDR

In this article, an open method to simulate the behavior of a glass furnace regenerator is presented, based on the Boussinesq approximation with a "fictitious thermal expansion coefficient".About:

This article is published in Applied Thermal Engineering.The article was published on 2005-10-01 and is currently open access. It has received 28 citations till now. The article focuses on the topics: Forced convection & Regenerative heat exchanger.read more

Figures

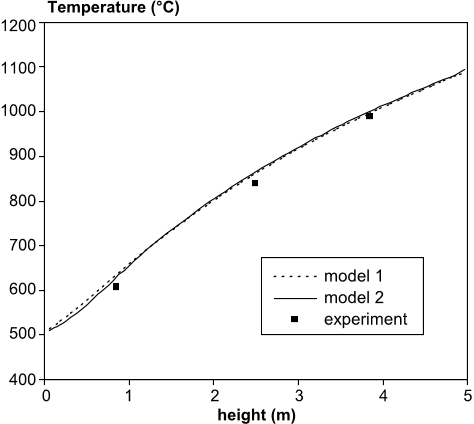

Fig. 15. Wall temperature profile in the middle of the period. ![Fig. 4. Evolution of the dimensionless velocity profile as a function of the distance to the wall when Grz = 8.44 · 1010: comparison between our numerical results and Ref. [28].](/figures/fig-4-evolution-of-the-dimensionless-velocity-profile-as-a-1sv6bmi9.png)

Fig. 4. Evolution of the dimensionless velocity profile as a function of the distance to the wall when Grz = 8.44 · 1010: comparison between our numerical results and Ref. [28].

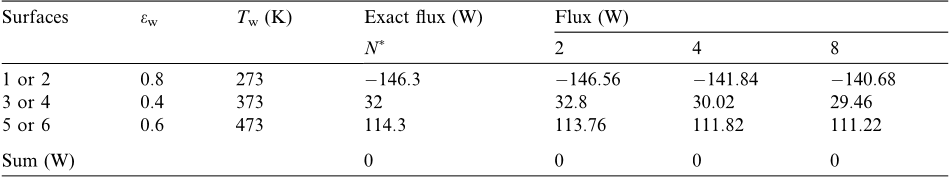

Table 2 Results of the test for a transparent medium ![Fig. 3. Evolution of the local heat transfer coefficient along the plate: comparison between our numerical results and Ref. [28].](/figures/fig-3-evolution-of-the-local-heat-transfer-coefficient-along-9sj31awp.png)

Fig. 3. Evolution of the local heat transfer coefficient along the plate: comparison between our numerical results and Ref. [28].

Fig. 8. Dimensions of the enclosure used for testing the radiative model.

Table 3 Results of the test for a semi-transparent medium

Citations

More filters

Journal ArticleDOI

A thermal energy storage process for large scale electric applications

TL;DR: In this paper, a new type of thermal energy storage process for large scale electric applications was presented, based on a high temperature heat pump cycle which transformed electrical energy into thermal energy and stored it inside two large regenerators, followed by a thermal engine cycle which transforms the stored thermal energy back into electrical energy.

Journal ArticleDOI

Pumped Thermal Electricity Storage: A technology overview

Alberto Benato,Anna Stoppato +1 more

TL;DR: A literature survey on the Pumped Thermal Electricity Storage technology is presented with the aim of analysing its actual configurations and state of development in this article, which is the most promising one due to its long cycle life, no geographical limitations, no need of fossil fuel streams and capability of being integrated into conventional fossil-fuelled power plants.

Journal ArticleDOI

Heat transfer—A review of 2005 literature

Richard J Goldstein,W. E. Ibele,Suhas V. Patankar,Terrence W. Simon,Thomas H. Kuehn,Paul J Strykowski,Kumar K. Tamma,Joachim Heberlein,Jane H. Davidson,John C. Bischof,Francis A Kulacki,Uwe Kortshagen,Sean C. Garrick,Vinod Srinivasan,Kalyanjit Ghosh,Rajat Mittal +15 more

TL;DR: A review of the heat transfer literature published in 2005 can be found in this article, where the authors restrict themselves to papers published in English through a peer-review process, with selected translations from journals published in other languages.

Journal ArticleDOI

Performance and cost evaluation of an innovative Pumped Thermal Electricity Storage power system

TL;DR: In this article, a new Pumped Thermal Electricity Storage configuration is proposed and tested, where an electric heater is used to convert electrical energy into thermal energy, a single heat exchanger is installed and air is used as heat transfer fluid.

Journal ArticleDOI

Performance analysis for glass furnace regenerator

TL;DR: In this article, a regenerator model is developed to estimate the actual performance of the regenerator and to compare it with the target performance, based on mass and energy balance of streams along with heat transfer characteristic equations.

References

More filters

Journal ArticleDOI

The prediction of laminarization with a two-equation model of turbulence

W.P. Jones,Brian Launder +1 more

TL;DR: In this article, the local turbulent viscosity is determined from the solution of transport equations for the turbulence kinetic energy and the energy dissipation rate, and the predicted hydrodynamic and heat-transfer development of the boundary layers is in close agreement with the measured behaviour.

Journal ArticleDOI

Application of the energy-dissipation model of turbulence to the calculation of flow near a spinning disc

Brian Launder,B. I. Sharma +1 more

Journal ArticleDOI

A Finite-Volume Method for Predicting a Radiant Heat Transfer in Enclosures With Participating Media

G. D. Raithby,E. H. Chui +1 more

TL;DR: A new finite-volume method is proposed to predict radiant heat transfer in enclosures with participating media and test results indicate that good accuracy is obtained on coarse computational grids, and that solution errors diminish rapidly as the grid is refined.

Journal ArticleDOI

Studies of mixed convection in vertical tubes

TL;DR: In this paper, the authors provide an up-to-date review of mixed convection heat transfer in vertical tubes, divided into two sections, the first dealing with laminar flow, and the second with turbulent flow.