Linköping University Post Print

α-alumina coatings on WC/Co substrates by

physical vapor deposition

T.I. Selinder, E. Coronel, Erik Wallin and Ulf Helmersson

N.B.: When citing this work, cite the original article.

Original Publication:

T.I. Selinder, E. Coronel, Erik Wallin and Ulf Helmersson, α-alumina coatings on WC/Co

substrates by physical vapor deposition, 2009, International journal of refractory metals

& hard materials, (27), 2, 507-512.

http://dx.doi.org/10.1016/j.ijrmhm.2008.10.007

Copyright: Elsevier Science B.V., Amsterdam.

http://www.elsevier.com/

Postprint available at: Linköping University Electronic Press

http://urn.kb.se/resolve?urn=urn:nbn:se:liu:diva-15359

α-ALUMINA COATINGS ON WC/Co SUBSTRATES BY PHYSICAL VAPOR

DEPOSITION

T.I. Selinder*, E. Coronel*, E. Wallin**, U. Helmersson**

*Sandvik Tooling, SE-126 80 Stockholm, Sweden

**Plasma and Coatings Physics Division, IFM Material Physics, Linköping University,

SE-581 83 Linköping, Sweden

Abstract

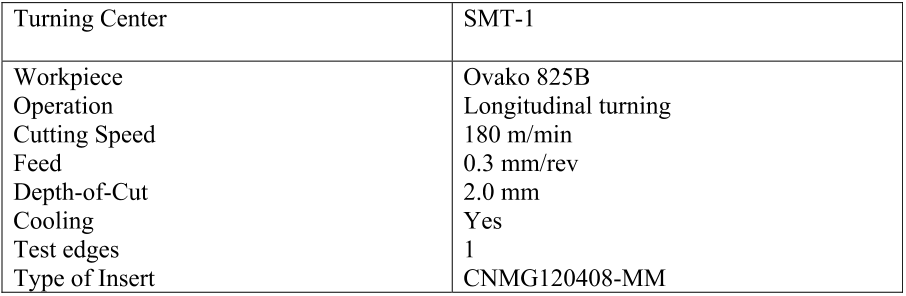

Physical vapor deposition coatings for cutting tools may be deposited by, e.g. reactive

magnetron sputtering. Alumina growth in Ar/O

2

gas mixtures gives rise to problems due

to insulating layers on targets, and hysteresis effects with respect to oxygen gas flow. In

this paper is described a technology for the deposition of crystalline alumina: reactive

high power impulse magnetron sputtering. Pure Al was used as target material, and the

cemented carbide (WC/Co) substrates were kept at 500-650ºC. Hysteresis effects with

respect to oxygen gas flow were alleviated, which enabled stable growth at a high

deposition rate. The high power impulses were helpful in obtaining a crystalline oxide

coating. X-ray diffraction and cross-section transmission electron microscopy showed

that α-alumina films were formed. Technological testing of these PVD alumina

coatings, with state-of-the-art AlTiN as benchmark, showed significantly improved

crater wear resistance in steel turning.

Keywords: HiPIMS, HPPMS, ionized-PVD, alumina, corundum

Page 1 of 18

Introduction

Hard physical vapor deposited (PVD) coatings may be coated by a variety of methods,

e.g. direct current (DC) magnetron sputtering in Ar inert gas. Reactive sputtering in

Ar/oxygen gas mixtures, may be used to grow oxides, but for insulators, in particular

alumina, this gives rise to problems due to the formation of insulating layers.

Conducting surfaces are a prerequisite to sustain an electrical glow discharge in DC

mode. These problems are circumvented in the bipolar pulsed magnetron technique

(BPDMS) [1-2], in which two magnetrons work in pair, alternating as anode and

sputtering target. By using pulse frequencies in the range of a few kHz the Al erosion

rate exceeds the rate of oxide formation at each target surface. Albeit stable, BPDMS

has only been repeatedly successful in depositing γ-alumina, which is a drawback if

phase stability of the coating is of concern. So far, commercial α-alumina coatings have

only been grown by chemical vapor deposition (CVD) at relatively high substrate

temperatures. In order to coat heat sensitive substrates, e.g. polycrystalline c-BN, high

speed steel, brazed tools, etc. the process temperature needs to be reduced. For this and

other reasons research and development on PVD alumina by, for instance, dual

magnetron sputtering [3], and arc evaporation [4] has been intense for the past few

years. Preoxidation of Cr-containing surfaces have enabled nucleation and growth of α-

alumina [5], but still requires substrate temperatures of 700-750ºC. A commercial

technology capable of growing highly crystalline mixed oxides (Al,Cr)

2

O

3

by the arc

method at temperatures below 600ºC were recently made available on the market [6],

but the commercialization of pure PVD α-alumina still remains. In this context the

novel technology high power impulse magnetron sputtering (HiPIMS) [7,8]have been

studied because this intermittent very high energetic sputtering technique widens the

Page 2 of 18

possibilities of supplying energy to the growth surface, which likely is the key to

success in nucleating α-alumina, and sustaining its growth. The HiPIMS technique has

been studied for deposition of both conducting coatings [9] as well as for oxide coatings

[10-11]. The degree of ionization of the sputtered material may be higher than for

traditional sputtering but the ionized species also accelerate towards the target, so-called

self sputtering, that has a lower sputtering yield than that of Ar sputtering. Therefore

one drawback with HiPIMS has been the inherently low growth rate. Recently, it was

shown that high rate sputtering is possible, and that long time stable operation of Ar/O

2

discharges is possible without feedback control of the reactive gas [12]. Stoichiometric

alumina was grown, with a phase structure that was dependent on substrate temperature;

at temperatures as low as 650ºC α-alumina was the only crystalline phase detected by

X-ray diffraction (XRD). Initial transmission electron microscopy (TEM) studies

revealed, however, that γ-alumina may grow, at least during the early stages in film

growth directly on WC/Co. XRD indicates that at the same temperature and identical

growth conditions AlTiN pre-coated substrates tend to favor growth of α- over γ-

alumina. A possible origin of this difference is discussed.

Experimental details

Coatings were made in a laboratory scale ultra-high vacuum system, with a base

pressure of less than 3×10

-5

Pa. A planar, 50mm diameter shuttered magnetron

sputtering source was mounted with a pure (99.999%) 3mm thick Al target. Cemented

carbide, WC10%Co (H10F), substrates were mounted flat on a resistive heater directly

above the magnetron, at a distance of 11 cm. Temperatures during different runs were

maintained at 650, 575, and 500 ºC. In order to grow films on cutting edges ISO style

Page 3 of 18

CNMG120408-MM H10F substrates were mounted, two at a time, on a tilted holder.

One nose and cutting edge was directed towards the magnetron. In this way both the

tool rake and flank faces were coated. In the latter case, however, it is estimated that the

real substrate temperature is approx. 50ºC less than the nominal set value. The

temperature reported herein is always the set nominal temperature, however, not the

estimated temperature. Substrates were either floating, or bias was applied by radio

frequency (RF) by an Advanced Energy RFX-600 power supply.

A fixed 99.997% pure Ar flow was adjusted to establish a pressure of 2.7 Pa. The

substrates were sputter etched for 15 minutes in an RF glow discharge resulting in a

-175 V DC bias of the sample holder, after which the pressure was reduced to 0.8 Pa,

and the sputtering initiated with the shutter closed. Sputtering was carried out by means

of a DC voltage source pulsed by a Melec SPIK1000A unit. The Al target was sputtered

at an average power of 110W (~5 Wcm

-2

) in pulses having a peak power in excess of

6kW, or 300 Wcm

-2

. The process working point was controlled by selecting the

99.9995% pure oxygen flow, to a value of approximately 2% of the Ar flow. The

oxygen flow was determined empirically so that transparent coatings were deposited. It

is expected that substrate oxidation during this stage is low: As the oxygen was

introduced when the discharge was running with the shutter closed it is reasonably

assumed that the partial pressure of oxygen is low in the deposition chamber; in the

working point chosen it is to a large extent consumed, incorporated in the growing film.

Also, there were no visible discolorations, after coating runs, of uncoated substrate

surfaces exposed to the sputtering atmosphere. To the extent of the analyses performed

in the present work the process was reproducible, in that consecutive runs under the

Page 4 of 18

![Fig. 5. Cross-section TEM bright field image and SAED pattern (inset) obtained from an alumina coating deposited on WC/Co at 650ºC. The SAED was obtained from an area close to the center of the coating showed in this micrograph. ZA = [2,1,1].](/figures/fig-5-cross-section-tem-bright-field-image-and-saed-pattern-csmo98n6.png)

![Fig. 1. Sputter deposition rate (a) and simulation (b) of deposition rate in the reactive Al/oxygen system as function of the oxygen flow in DC and in HiPIMS mode of operation [12].](/figures/fig-1-sputter-deposition-rate-a-and-simulation-b-of-3oa24axd.png)