A Chip and Pixel Qualification Methodology on Imaging Sensors

Yuan Chen, Steven M. Guertin, Mihail Petkov, Duc N. Nguyen, Frank Novak

2

Jet Propulsion Laboratory, California Institute of Technology , 4800 Oak Grove Drive, MS 303-230, Pasadena, CA 91109

2

NASA Langley Research Center, MS 468, 5 North Dryden St., Hampton, Virginia 23681

Phone: 818-393-0940; Fax: 818-393-4559; E-mail: yuan.chen@jpl.nasa.gov

ABSTRACT

This paper presents a qualification methodology on

imaging sensors. In addition to overall chip reliability

characterization based on sensor’s overall figure of merit, such as

Dark Rate, Linearity, Dark Current Non-Uniformity, Fixed Pattern

Noise and Photon Response Non-Uniformity, a simulation technique

is proposed and used to project pixel reliability. The projected pixel

reliability is directly related to imaging quality and provides

additional sensor reliability information and performance control.

[Keywords: CMOS Active Pixel Sensors, PD-APS, Imaging Sensor

Reliability, Pixel Reliability.]

INTRODUCTION

Imaging sensors of different varieties are widely used in

commercial and scientific applications. Compared to charge-coupled

device (CCD) image sensors, CMOS active pixel sensor (APS)

imagers are fabricated in standard CMOS processes, which make it

possible to integrate the timing and control electronics, sensor array,

signal processing electronics, analog-to-digital converter (ADC) and

full digital interface on one chip. This helps to achieve a cost-

effective highly integrated and highly compact imaging system, i.e.

camera-on-a-chip, by utilizing the same design techniques that have

been developed over the years for low-power CMOS digital and

analog circuits.

There have been extensive research efforts to enhance the

performance of the CMOS APS imaging sensors by adopting more

robust digital/analog circuit designs and sampling techniques, as

well as more advanced imaging processing technology and

semiconductor fabrication technologies [1-9].

On the other hand, few studies have concentrated on the

reliability or qualification of the imaging sensors. It is taken for

granted that the reliability of the imaging sensors should be

automatically guaranteed when the semiconductor process

technologies fabricating the imaging devices have been qualified.

However, unlike memory chips where failed bits can be detected by

functional testing and can be easily recognized as bad bits, pixels of

the imaging sensors can either be uniformly degraded or become

“hot” pixels. In both cases, imaging problems or decreased imaging

quality will result.

In the effort of qualifying a photodiode-type (PD) CMOS

APS imaging device for one of our space mission applications, we

developed a qualification procedure and reliability analysis approach

for imaging sensors. It should be noted that the environmental,

mechanical and packaging evaluation procedures and tests are also

part of the qualification plan and practice, but are not addressed

herein. In addition, the impact of radiation on the imagers -

including Gamma, protons and heavy ions - were presented in [10].

In this paper, a qualification methodology on imaging

sensors is presented. The experimental details of the accelerated life

testing will be described first, along with the reliability

characterizations on the imaging sensors. Then, the projection for

overall chip reliability and a simulation approach to correlate pixel

reliability and image quality will be presented, followed by

summary.

EXPERIMENTAL DETAILS

The image sensor is photodiode-type CMOS active pixel

sensor imaging system on chip, designed by Jet Propulsion

Laboratory and manufactured by a standard commercial CMOS

production line. The imager is a 512 by 512 photodiode pixel array,

which can randomly access any window in the array from 1 pixel by

1 pixel all the way to 512 pixels by 512 pixels in any rectangular

shape. The minimum interface consists of five wires: Vdd, Ground,

Serial Data Input, Serial Data Output and Clock. The imager size is

approximately 10 mm by 15.5 mm with pixel size of 12 um by 12

um. The nominal power supply Vdd is 3.3V.

Figure 1 gives a schematic of the photodiode-type active

pixel sensor cell [1, 3-4, 11]. In the pixel sensor cell, the transistors

designed for the imagers in our study have a minimum channel

length of 0.5um.

Vdd

row sel

M1

M2

M3 col sel

Figure 1. Schematic of the photodiode-type active pixel sensor cell.

Light into the photo-diode generates a small current

proportional to the light intensity and photo-diode area. Due to this

small photo current, the nMOS transistor (M1) operates in weak

inversion. In this region, the gate to source voltage depends

logarithmically on the drain current with a constant slope

independent of the technology and equal to kT/q, as shown in the

following simplified expression for the gate-source voltage for a

transistor working in its weak inversion region [3-4,11]:

th

d

d

gs

V

I

I

W

L

q

kT

V += )ln(

0

where V

gs

is the gate-source voltage, I

d

is the drain current or the

photo current, I

d0

is the I

d

at the on-set of weak inversion, W and L

are the width and length of the channel of the transistor, T is the

temperature in Kelvin and k is the Bolzmann constant. Therefore,

the pixel structure yields a continuous signal that is proportional to

the instantaneous light intensity.

Because of the characteristic deviation of the active

transistor M1 in the pixel cell, non-uniformity among pixels is

expected. Therefore, the following parameters are some important

figures of merit for imaging sensors.

Fixed pattern noise (FPN) is the variation from pixel to

pixel when the imager operated as normal with no light input. The

FPN is typically measured using the full array. Photon Response

Non-Uniformity (PRNU) is the gain difference between pixels and it

is typically taken with a field at approximately 50% of full well.

Dark Current is the thermally generated electrons discharging the

pixel just as if a photon had hit the pixel. Dark Current Non-

Uniformity (DCNU) is the leakage difference between pixels with a

dark field over a long integration time. All these parameters are

functions of temperature and measured during the accelerated

testing. Also, Dark Rate and Linearity, defined as the mV/s from

Dark Current and PRNU measurements, respectively, were also

monitored.

Shown in Figure 2, the accelerated testing was fully

controlled by LabView software running on a personal computer.

The image sensors were stressed in parallel and stopped in a pre-set

time interval to be monitored one by one for Dark Rate, Linearity,

Dark Current Non-Uniformity (DCNU), Fixed Pattern Noise (FPN)

and Photon Response Non-Uniformity (PRNU).

Figure 2. Schematic of the accelerated testing set-up.

The accelerated testing was performed on the image

sensors at elevated bias and temperature levels to accelerate

thermally activated failure mechanisms. It is very important to

ensure that the highest stress temperature cannot exceed the glass

transition temperature for the die attach material of the packages, in

our case, 117°C. At the same time, the highest stress voltage at each

stress temperature should be within the range when the sensor is still

framing and functional. The highest voltage that can be applied on

the imager when it is still framing was simulated as 6.8V, later

confirmed by experiment.

Following this procedure, the stress conditions were

determined as 6.5V at 85°C, 6.5V at 45°C, and 6.0V at 85°C to

estimate voltage acceleration factor and activation energy. The total

testing sample size was 18 with 5~6 imager sensors for each

accelerated stress condition. The limited number of stress conditions

in our case results from cost constraints. Additional stress conditions

and more testing samples can be utilized to further refine the bias

and temperature acceleration factors. Figure 3 gives the stress

condition matrix with the mission operating condition and the

recommended additional stress conditions.

3

3.5

4

4.5

5

5.5

6

6.5

7

-40 -20 0 20 40 60 80 100

Temperature (C)

Bias (V)

Stress Conditions Used

MIssion Operating Condition

Recommended Additional Stress Conditions

Figure 3. Stress matrix for the accelerated testing.

During the accelerated testing, the sensors were running at

5 MHz with the clock pulse matching the stress voltage applied on

the chips. A green LED carefully designed and tuned on each testing

board served as the light source within the chamber for Linearity and

Photon Response Non-Uniformity measurements. A typical clock

frequency during the mission operating condition is 4MHz.

The imagers were first characterized under each stress

temperature condition to determine an appropriate integration time.

The integration time was chosen to be 30ms during FPN and PRNU

measurements to represent the mission operating condition. The

integration time during dark rate and Linearity measurements was

chosen long enough for the imagers to reach saturation region for a

full characterization of the imaging response.

CHIP RELIABILITY PROJECTION

For overall VIDI APS chip reliability, Linearity and Dark

Rate are the two parameters to be considered since they reflect the

overall parametric shift or change on the imaging chips.

Figure 4 shows the linearity characteristics for the worst

case chip as a function of stress time. The black symbol indicates the

response at time zero while the white symbol indicates response at

the end of stress testing. The characteristics trend is representative

for all imaging chips under all stress conditions.

time (ms)

0 20 40 60 80 100 120 140 160 180

linearity (mV/s)

0

200

400

600

800

1000

1200

1400

Figure 4. Linearity changes with stress time, black symbols indicate

time zero, white symbols indicate at the end of stress.

Agilent 33120A

Function Generator

Agilent 3631A

DC Power Supply

PC

Interface

Board

APS chips

Stressed

In Parallel

Figure 4 indicates that it took a longer integration time to

achieve saturation when the device was degraded. This information

can be also presented by the slope of the linearity curves before the

saturation points. The percentage of the slope change of the linearity

curves in Figure 4 is plotted in Figure 5, showing almost linear

increasing Linearity slope versus stress time in a log-log scale.

stress time (s)

1e+5 1e+6 1e+7

Linearity slope change (%)

1

10

100

Figure 5. Linearity slope change with stress time.

The behavior of the dark rate is similar to that of Linearity

but with smaller degradation rate. Figure 6 shows a representative

change of the dark rate slope as a function of stress time in a log-log

scale.

stress time (s)

1e+5 1e+6 1e+7

Dark Rate slope change (%)

0.1

1

10

Figure 6. Dark rate slope change with stress time.

Since the Dark Rate and Linearity can indicate the overall

sensor performance, the sensor’s overall chip reliability can be

projected based on the Dark Rate and Linearity degradation.

Assuming the Arrhenius model [12]

o

a

o

kT

E

V

eet

β

~

%

where t

%

is the chip life time at certain failure fraction and is

determined to be 0.1% in our case; β, V

o

, E

a

, k and T

o

are the

voltage acceleration factor, operating voltage, activation energy,

Boltzmann’s constant and operating temperature in Kelvin,

respectively.

The voltage acceleration factor and activation energy were

estimated as 0.73 dec/volt and 0.7eV, respectively, for worst case

imaging chips. Using 10% degradation for Linearity as the chip

failure criterion, the chip life time at 3.3V, 27°C is over 112 years at

0.1% failure fraction with average failure rate of 1 FIT. Life and

failure rate can be also generated by using a percentage degradation

of Dark Rate as well.

It should be noted that the “failure” criteria used in this

reliability projection is defined as a certain level of parametric

shifting. Even though this parametric shifting does indicate some

performance degradation of the imagers, it is worthwhile to note that

the imagers still frame and function very well when the Dark Rate

and/or Linearity reaches 10% parametric degradation. In order to

estimate life and failure rate associated with the “imaging failures”,

pixel reliability needs to be projected.

PIXEL RELIABILITY PROJECTION

In the previous section, chip reliability projection indicates

reliability for a sensor’s overall performance as a function of

operation time, but it is difficult to relate it to image quality.

Therefore, pixel reliability needs to be considered and projected as

well.

The Dark Current Non-Uniformity, Fixed Pattern Noise

and Photon Response Non-Uniformity measurements during the

accelerated testing recorded the distributions of the photodiode

reference voltage for each pixel as a function of stress time, in order

to calculate the time-dependent DCNU, FPN and PRNU values.

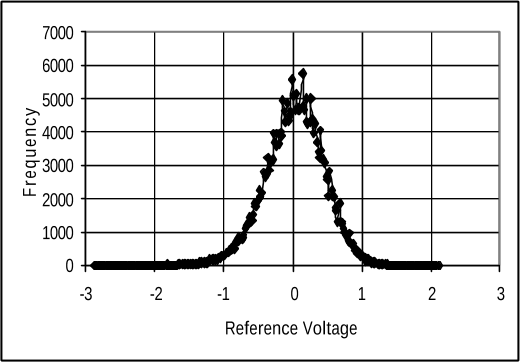

Figure 7 shows an example of the distributions of pixel

responses during FPN measurements with FPN suppression function

enable at 27°C.

0

1000

2000

3000

4000

5000

6000

7000

-3 -2 -1 0 1 2 3

Reference Voltage

Frequency

Figure 7. Pixel response during FPN measurement at 27°C.

During the accelerated testing, some of the pixels get

“hotter”, i.e. leak more than nominal pixels. In addition, the standard

deviation of the pixel distribution increases slightly with worst case

of 2% change, and the median of the distribution eventually shifts.

Based on our sample size of 20 CMOS active pixel

sensors (18 for accelerated testing and 2 for characterization testing)

with 512 by 512 pixels on each imager, we found that the “hot”

pixels tend to be randomly distributed across the pixel array and no

signature of the pattern can be found. This may indicate that the

imaging chips do not have evident process-related defects or stress-

induced weak-link pixels. The hot pixel generation rate is slow at

the accelerated stress levels. Based on the limited data, the estimated

hot pixel generation rate is approximately one and one-half pixel per

decade at 6V 85°C, which gives a rather long projected imager life,

assuming a few hot pixels do not have a severe impact on imaging

quality. Hot pixels do not seem to induce neighboring pixel to

degrade faster. Hot pixels can cause image problems but with a

proper refreshing scheme, the impact of hot pixel on imaging quality

can be significantly reduced.

The change in standard deviation of the pixel distribution

seems to increase faster at the beginning of the accelerated stress

conditions and then saturates at about 2% to 3% change. However,

due to the limited data sets and small sample size in our study, no

further conclusion can be made on the behavior of the standard

deviation change.

When the pixel distributions under DCNU, FPN and

PRNU measurements have shifted and/or the standard deviations

have changed, it indicates a change in black-white scale for imaging.

Therefore, by scaling the time-dependent pixel distribution against

the initial pixel distribution, images can be generated either by real

pixel distribution data or by projected pixel distributions.

The pixel distributions for DCNU, FPN and PRNU did not

have significant shift during our accelerated testing. This can be

expected since the minimum channel length of the active transistor

inside the pixel cell is rather “long”, i.e. 0.5 um. Therefore, based

on the trend of pixel degradation, the projected pixel distributions

can be and needed to be generated to simulate the image quality.

Figure 8 shows an original image of Saturn. Figure 9, 10

and 11 are the simulated images with 10%, 15% and 20% median

pixel degradation, respectively. The degradation on the imaging

quality can be seen very clearly from these Figures, thus a so-called

“imaging failure” can be determined based on the series of images.

For example, if Figure 8 is regarded as an imaging fail, a 10%

median pixel degradation is then chosen as the failure criterion. In

this case, the imager life is at least an order of magnitude longer than

the projected imager life using 10% Linearity degradation.

Figure 8. Original image of Saturn

Figure 9. Image with pixel degradation

(Median percentage change is 10%).

Figure 10. Image with pixel degradation

(Median percentage change is 15%).

Figure 11. Image with pixel degradation

(Median percentage change is 20%).

Figure 8-11. Imaging quality simulation with different level of pixel

degradation.

Another failure mechanism results from the read-out or

I/O circuitry. It happens rather suddenly when the imager stops

functional totally. Competing with the pixel degradation, which is a

relatively slower process, periphery circuitry failure may be much

more severe since it will cause a hard failure of the imager. This

happened during radiation testing when the imager failed in a

sudden owing to the periphery circuit failure.

The pixel reliability is a function of acceptable image

quality level and depends on the pixel responses to darkness and

light. Acceptable image quality can be chosen based on the same

experimental data or simulation results using small degradation

percentage increases. It should be noted that the reliability projection

based on the worst case parameter degradation, i.e. linearity

degradation, gives a much shorter lifetime prediction compared to

the pixel projection. Therefore, pixel reliability cannot be

overlooked during imaging sensor qualification.

SUMMARY

A reliability study on a CMOS active pixel sensor imaging

system is presented. While a reliability projection based on the

imaging sensor’s overall parametric performance may provide some

insight on the imager performance degradation, pixel reliability

projection, either by experimental or by predicted pixel distributions,

has to be performed. The projected pixel reliability can be directly

related to imaging quality and provide additional sensor

performance information.

REFERENCES

1. E. R. Fossum, “CMOS Image Sensors: Electronic Camera-

on-a-Chip”, IEEE Transactions on Electron Devices, Vol.

44, No. 10, pp. 1689-1697, October, 1997.

2. J. Janesick, “Lux transfer: Complementary metal oxide

semiconductors versus charge-coupled devices”, Opt. Eng.

41(6), 1203-1215, June, 2002.

3. F. Pardo, et al, “CMOS Foveated Image Sensor: Signal

Scaling and Small Geometry Effects”, IEEE Transactions

on Electron Devices, Vol. 44, No. 10, pp. 1731-1737,

October, 1997.

4. D. Scheffer, et al, “Random Addressable 2048 X 2048

Active Pixel Image Sensor”, IEEE Transactions on

Electron Devices, Vol. 44, No. 10, pp. 1716-1720,

October, 1997.

5. S. Mendis, et al, “CMOS Active Pixel Image Sensor”,

IEEE Transactions on Electron Devices, Vol. 41, No. 3,

pp. 452-453, March, 1997.

6. G. Deptuch, et al, “Design and Testing of Monolithic

Active Pixel Sensor for Charged Particle Tracking”, IEEE

Transactions on Nuclear Science, Vol 49, No. 2, p601-

610, 2002.

7. J. Nakamura, et al, “On-focal-plane signal processing for

current-mode active pixel sensors”, IEEE Transactions on

Electron Devices, Vol 44, pp. 1747-1758, 1997.

8. R.H. Nixon, et al, “128 X 128 CMOS photodiode-type

active Pixel Sensor with on-chip Timing Control and

Signal Chain Electronics”, Charge-Coupled Devices and

Solid-State Optical Sensors V, Proceedings of SPIE, Vol.

2415, pp. 117-123, 1995.

9. O. Yadid-Petch and E.R. Fossum, “Wide Intrascene

Dynamic Range CMOS APS Using Dual Sampling”,

IEEE Transactions on Electron Devices, Vol 44, pp. 1721-

1723, 1997.

10. L. Scheick, F. Novak, “Hot Pixel Generation in Active

Pixel Sensors: Domeimetric and Microdosimetric

Response”, Radiation and its Effects on Component and

Systems, Noorwikj, Netherlands, September, 2003.

11. N. Ricquier and B. Dierickx, “Pixel Structure with

Logarithmic Response for Intelligent and Flexible Imager

Architectures”, Microelectron. Eng., Vol. 19, pp. 631-

634, 1992.

12. W. Nelson, “Accelerated Testing”, John Wiley & Sons,

New York, 1990.

ACKNOWLEDGEMENTS

This work was carried out at Jet Propulsion Laboratory,

California Institute of Technology, under a contract with the

National Aeronautics and Space Administration. The authors also

would like to thank Dr. Bedabrata Pain and Chris Wrigley for

helpful technical discussions.